Blackgrass control last season was generally below par but it wasn’t necessarily down to resistance. CPM canvasses expert opinion on which small changes can provide the biggest gains in the fight against blackgrass.

In dry years, the best strategy is to do as little as possible and let nature take its course.

By Lucy de la Pasture

The harvest is off, autumn seed’s purchased and the early birds are cracking on with field work. Blackgrass control is all about incremental gains, say experts, and these days relies on putting together a plan of attack that incorporates both chemical and cultural control in an effort to achieve the 97% control needed to keep blackgrass from gaining the upper hand.

This makes the gap between harvest and drilling a crucial slot for blackgrass control – crop-free fields are the best opportunity for some serious weed control. So what can growers do in the coming weeks before drilling and the pre-em programme?

Seed mortality is the number one priority. Eliminating viable blackgrass seed is essential, but this doesn’t always mean repeated

John Cussans believes going to all the effort of greening up fields then spraying them off may not be doing much for overall control.

cultivations and glyphosate as John Cussans of NIAB explains.

“There seems to be an over-riding assumption that if you can get blackgrass seedlings to germinate before you drill, then you’ll reduce the blackgrass population in the crop. But if you look at data from published UK data and from overseas, then there isn’t actually a very strong relationship between the amount of blackgrass you get to germinate before you drill and the blackgrass that you get in the following crop.”

This begs the question whether all the effort that goes into greening up fields then spraying off is doing much for overall control? According to John Cussans, the answer to this depends on the weather – the one thing we have no control over.

“If you compare dry and wet years in the data, then the best strategy diverges and become opposites. In dry years, the best strategy is to do as little as possible and let nature take its course. But in wetter conditions, which promote survival, anything you can do to promote germination will help to reduce the subsequent burden.”

Dry surface conditions are quite hostile to blackgrass and other weed seeds. Fluctuating temperatures, little moisture, UV radiation and biological activity all cause many of them to perish – known as direct seed mortality. Anything that increases soil contact can reduce direct mortality, he explains.

“The fact that we haven’t taken sufficient account of this part of the weed’s biology is perhaps why true no-till systems seem to work better with respect to weed management than you’d expect from existing models of the system,” he notes.

“Rolling and superficial cultivation take seeds from the surface and integrate them into the surface zone within the soil – so we’re not talking about deep cultivations, just the things people normally use to stimulate blackgrass germination by increasing seed-soil contact. In dry years, this small amount of soil disturbance can actually protect seeds from the harsh elements.”

Agrovista trials have shown that adding Remix to the pre-em herbicide (right) improves efficacy of a 0.6 l/ha application of Liberator through an air-inclusion nozzle.

In wetter years, the target is to achieve more indirect seed mortality – germination followed by destruction of the weed with a spray or steel. The important thing to keep in mind is that there needs to be a gap of about three weeks between cultivation and any subsequent spray. It needs this time so that all the weeds that can germinate, will germinate, he says.

John Cussans is keen to emphasise that by wet or dry years he doesn’t mean the occasional wonderful or appalling summer, but simply above or below average rainfall for the month after harvest. Less than 50mm in that month would count as a dry year according to his research.

Because the UK weather is inherently variable, in some years you can get a good dry spell for direct seed mortality, followed by rainfall towards the end of Sept which aids drilling and the activity of pre-em herbicides.

But in other years, all the factors can turn against you. 2012 was one of these, where it was wet post-harvest, increasing weed seed survival, and then conditions weren’t right for pre-ems so the blackgrass romped away, he says.

Although, we’re now halfway through the post-harvest window, now’s a good time to review progress and finalise the steps for drilling and pre-ems, reckons Ben Giles of Bayer.

“As John explains, conditions and decisions straight after harvest are important but now you need to work out what that means for establishment. Not everyone has the luxury of leaving land uncultivated – for example if you chop and incorporate straw the decision’s been made for you.

“There was high seed return from blackgrass this season, so there’s a case for spring crops on some fields. Investing in establishment and herbicides when blackgrass numbers are already very high makes no sense. Focus effort on land which can be managed well and deal with the other land later,” he advises.

The target drilling date where blackgrass is a problem is from mid-Oct onwards, so mid-Sept is the time for the final and perhaps only stale seedbed. This objective is to capture the dangerous autumn germinating blackgrass which swamps crops when you drill too early, he points out.

“The main operations for establishment are best completed in quick succession: spray off, drill, roll then apply the pre-em. Any delays will give weeds an opportunity which you can’t afford, so only drill the crops when you know you can come back with the sprayer for the pre-em.

“A good philosophy for pre-em programmes is to hit them hard and hit them early. Bayer has carried out research over many seasons and using Liberator (flufenacet+ diflufenican) at the true pre-em timing is the key to blackgrass control.”

Drilling in mid-Oct means there’s less likely to be an issue with soil moisture, which is necessary for residual herbicides to move and take effect in the soil. Even if it’s dry, the herbicides persist in the soil so can take advantage of moisture when it arrives, he advises.

Pairing Liberator with other residuals is the obvious way to boost overall control and protect herbicides from resistance as Ben Giles explains, “We’re in a situation where quite a small number of actives are doing the work on blackgrass every year, so everything you can do to support them with more diverse chemistry is a plus. Most importantly it reduces blackgrass numbers ahead of a post-em follow up.”

And that’s where attention to detail when it comes to spray application comes in. According to Chris Martin of Agrovista, application has never been more important. As blackgrass control becomes reliant on residual herbicides, getting this part of the equation right can bring bigger benefits in terms of percentage blackgrass control than using more herbicide, he believes.

It’s an area Agrovista has been researching and they recommend a twin line on the sprayer for best results when applying residual herbicides, Chris Martin explains.

“It’s all about coverage when it comes to using residual herbicides and that means using higher water volumes and a finer spray quality – two things that don’t normally go together. We’ve found that the best way to achieve both of these at the same time is to use two angles of attack by using a forward-facing line at a 30° angle and a downward-facing line, gives the best results.

“In small trials, backward-facing nozzles can help deposition of residual herbicide on soil but when it comes to field application, the forward speed causes too much drift. Putting the second line of nozzles facing downwards compensates for the higher forward speed of the sprayer,” he says.

If you don’t have a twin line on the sprayer, all is not lost. “Twin caps facing forward and backwards can solve the problem if you put a Defy nozzle in forwards in the backward facing cap. This effectively converts the Defy nozzle to a downward facing nozzle and also has the same effect with the new 3D nozzles,” he adds.

James Thomas of Syngenta points out that if the Defy 3D nozzle is used in such a way then it no longer has a three- star LERAP rating, which is something growers may need to bear in mind.

“Syngenta recommend the Defy 3D nozzles are placed in alternating forwards and backwards positions along the boom, and this is based on 10 years of field trials and research carried out at Silsoe Spray Application Unit. Positioning the nozzles this way consistently gives the best spray deposition in more than 10,000 wind tunnel experiments,” he explains.

Paying attention to spray quality has a big impact on the chances of residual herbicides working, explains Chris Martin. “For the same water volume, a coarse spray of 400 microns will have one droplet, a medium quality spray of 200 microns produces 8 droplets. When it comes to using a fine spray of 100 microns then the number of droplets for the same water volume increases to 64.”

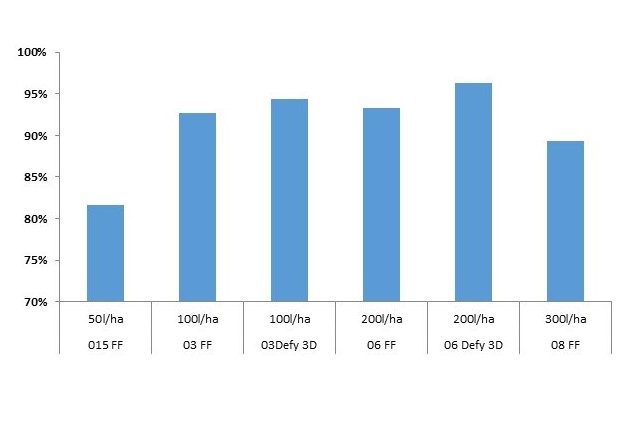

But the same isn’t necessarily true across all nozzle types, explains James Thomas. “While a flat-fan nozzle produces more droplets in a fine quality spray, the Defy 3D has been designed to optimise the droplet spectrum to reduce drift and our trials show that you can apply in a lower water volume (100-200 l/ha) and get the best coverage and control of blackgrass (see results in chart on pxx). When water volumes are 300 l/ha or more then there’s a drop-off in control, mostly due to the concentration factor and larger droplets.”

Another problem that can lead to poorer blackgrass control at the periphery of fields is a reduced coverage as the headlands are approached, explains Chris Martin. “As the sprayer slows down to turn on the headland, the pressure is reduced leading to a drop in spray angle and an increase in coarseness of the spray.”

He recommends using the adjuvant Remix to reduce this effect. By increasing the volume medium diameter (VMD) of the spray droplets –

essentially by losing the very fine droplets – adding Remix also helps reduce drift. Paying attention to the finer details of application can boost control of blackgrass regularly by as much as 30%, with even greater improvements possible where application practices were previously poor, he comments.

James Thomas reminds recommends that pre-ems are applied within 48 hours of drilling for best effect. “Drilling brings moisture to the surface which both encourages blackgrass seeds to germinate and activates the herbicide. Having the residual in place to act on the blackgrass as it starts growing and is most vulnerable is what you’re aiming for,” he says.

Farmers will measure the success of pre-em programmes with some caution following the way blackgrass fought back this spring. Mild conditions last winter meant that pre-ems weren’t backed up by winter kill, so the plants recovered in the absence of a few hard frosts in Dec, adds Bayer’s Ben Giles.

“The question is: can you guarantee a cold winter to support your pre-em programme? And the answer is no, so coming back with a post-em before Christmas is worth considering,” he believes.

Farm trials seek answers on adjuvants

As soon as spray quality gets into the finer spectrum, drift becomes a problem, but can adjuvants help address this? That’s what Dorset-based former spray operator of the year, Iain Robertson, has been investigating.

“I found it hard to understand how an adjuvant could help retard drift and increase coverage, as I felt this was a contradiction. But if it’s possible, then it could improve the number of spray days in the autumn.”

So Iain Robertson put aside his scepticism and decided to investigate to see how nozzle selection and the use of an adjuvant could help improve his herbicide application.

“Adjuvants were pretty much snake oil and wizardry to me but I wanted to answer the two questions – does an adjuvant increase coverage compared to water and does an adjuvant reduce drift?”

He set out to answer these queries using two nozzle types – 03 GuardianAir (air-induction nozzles) and 03 Defy 3D nozzles (flat fan 80° with an in-built 38° angle), alternating forward and backwards as best practice to ensure best coverage. The treatments he chose to compare were water alone, water with Back Row (Adj 0472) and water with Intracrop Stay Put (Adj 0507), applied through both sets of nozzles. Treatments were applied with the farm’s Bateman RB26 self-propelled 24m sprayer in a water volume of 100 litres/ha, at a forward speed of 12km/h.

As part of the experiment, he placed water sensitive paper (WSP) on the ground and on a wooden block, to replicate a clod so that he could see the pattern of spray deposition and assess coverage.

“The WSP showed there was better ground coverage when the adjuvants were added, regardless of the nozzle used. The Defy 3D gave superior coverage, especially around the ‘clods’ so would be my nozzle of choice, but if the weather conditions were sub-optimal then the Guardian Air would be the next option.

So what conclusions does Iain Robertson come to? “Adding an adjuvant, such as Back Row or Stay Put, to the tank-mix can improve the efficacy of a pre-em application. It appears to improve coverage and either extends the operating window that Defy 3D nozzles can work in, or if it’s too windy and a low drift option has to be considered, the adjuvant makes air-induction nozzles a good alternative,” he reckons, adding that he’ll be using the adjuvants he tested on the farm this autumn.

“I’ll also be using C-Cure (Adj A0467) as it contains an extra component binding the herbicides to the soil particles keeping it in the important top zone. I feel this is another important aspect that the adjuvants bring to the table,” he adds.

The puzzle of why the adjuvant reduced drift and improved coverage was also clarified by Iain Robertson’s WSP experiment. “The adjuvants don’t make the whole spectrum of droplets coarser, as I’d previously thought. They actually work by taking out the very finest droplets, most susceptible to drift.

“The outcome of using an adjuvant could be as dramatic as making the difference between a pre-em herbicide being applied well at the correct time or not at all,” he believes.

Agrovista has been recommending an oil-based adjuvant, Remix (Adj A0765), in their residual herbicide programmes for some time, says Chris Martin. “Remix contains a long-chain carbon molecule which carries a positive charge, creating a bond between the spray and negatively charged clay and organic matter particles in the soil.

“One of the things Remix does is keep the residual herbicide where it’s needed on the soil surface layers. We’ve found crop damage is reduced because the herbicide isn’t washed into the rooting zone of the crop – something that’s becoming even more important for crop safety as we’re using a stack of residual herbicides,” he notes.

Effect of water volume on blackgrass control

In 2016 trials, using the Defy 3D nozzles at 200 l/ha provided 96% control against blackgrass.

Source: Syngenta; assessed 12/05/16

John Cussans believes going to all the effort of greening up fields then spraying them off may not be doing much for overall control.