In the fourth of the 5 for 5 to beat blackgrass series, CPM finds out how delaying drilling is a crucial weapon against the pernicious grassweed.

Delayed drilling is the engine behind all the other control strategies.

By Lucy de la Pasture

The most important strategy to help growers get back on top of blackgrass is to delay drilling, believes Dr Stephen Moss.

“Delayed drilling is the engine behind all the other control strategies and the blackgrass problem can’t be solved without employing it. But the devil is in the detail. Delaying autumn sowings by 4-5 weeks and replacing autumn with spring drilling will help reduce blackgrass populations,” he comments.

With around 80% of blackgrass emerging in autumn, delayed drilling is a vital control tactic as it provides a longer window to kill the weed before a crop is sown. Spring cropping is the ultimate delayed drilling, providing a wide window to remove autumn-germinating blackgrass with stale seedbeds, additional cultivations and non-selective chemistry.

“Both delayed autumn and spring cropping was generally perceived as being an ‘impossibility’ by growers on heavy land just a decade ago and dismissed as a control option. But in recent years blackgrass has forced their hand and many growers have found that they can do both – the ‘impossible’ has become ‘possible’,” explains Stephen.

Stephen Moss believes that the worst thing that could happen for blackgrass control now would be the introduction of a highly effective new herbicide.

“When post-emergence herbicides worked well, there was less pressure to make the change,” he notes. “Although I doubt many would agree with me, I firmly believe that the worst thing that could happen for blackgrass control now would be the introduction of a highly effective new herbicide. The temptation would be to throw out the cultural controls we’re now successfully adopting, which would be a retrograde step.”

The big question is how many successive spring crops are necessary, as one spring crop isn’t likely to do the job, points out Stephen. “There’s no panacea, it will vary from field to field depending on the severity of the blackgrass problem. It may be that up to five successive spring crops will be needed, but this is where it’s important to record, review and revise after each crop.”

These three ‘R’s are an important part of the ‘5 for 5 to beat blackgrass’ strategy, he explains. “Continually assessing the success of your programme is essential. Record the amount of blackgrass and its location in every field, review progress each year and then be flexible, revise the plan if necessary. Dramatic improvements will take longer than the first couple of years.”

Frontier’s Dr Paul Fogg agrees, adding that it’s sometimes difficult to know when to drop in a ‘reset’ year using spring crops, even when you’ve got on top of the problem. “Based on the work we’ve done at our Staunton blackgrass site, more than one year of spring cropping is essential before returning to a first wheat in the rotation. Two years is preferable, and three years will give even better results.”

He advises growing a spring crop that has a good fit with the farm. “If you have access to an AD plant then it’s easy to utilise spring cropping around crops for biogas production. In other situations, spring wheat works well, but it needs high seed rates of 500-600 seeds/m2 to compensate for its reduced tillering capacity compared to spring barley.

“Spring oats can be an option if a contract is available, spring oilseed rape isn’t an option for many because of flea beetle and spring beans present a bit of a challenge,” he adds.

An alternative to spring crops is to rejig the rotation to include either grass leys or fallow, suggests Stephen. “Modern fallowing or grass can be useful to help manage blackgrass, but the question is what do you do at the end of the fallow or ley. The worst thing you could do is to work the soil and drill straight away. There needs to be a stale seedbed otherwise you miss the opportunity to exhaust the residual blackgrass seedbank and capitalise on what has been achieved in the previous few years.”

Changes in rotation aid blackgrass control

Ben Stroud manages arable and forage crop production on the family dairy–arable operation in partnership with his father and uncles. Situated on the Leics–Notts border, the farm has 222ha which supports 161ha of crops including 80ha of wheat and 170 dairy cows.

There’s always been moderate blackgrass pressure on the farm which Ben is keen to prevent getting worse. “Over the past two years the situation is much improved and I put that down to three things; crop rotation, delayed drilling and cultivation technique with more low disturbance and direct drilling.”

Ben Stroud uses a two-year grass ley or lucerne to help regain control of his worst blackgrass fields.

Land which has lower blackgrass pressure, which Ben defines as one or two heads but no really bad patches, has a winter cereal/oilseed rape rotation. For winter cereals, he prioritises drilling so that the worst fields get drilled last. On land with more blackgrass, a spring crop is included in the rotation because Ben doesn’t believe you can greatly reduce the level of blackgrass with just winter cropping.

“Spring barley is our preferred option because the straw is very useful for the dairy herd, but it also stacks up financially. On difficult blackgrass land we get a better gross margin from spring barley than winter barley or second wheat. This year, we are trialling a cover crop ahead of spring barley with the aim of helping to condition the soil and allowing us to get in earlier in the spring with the direct drill.”

Even where he remains committed to the winter crop rotation, Ben still drills late to help his blackgrass control. “This year winter barley went in on the 14 Oct and wheat from 15-27 Oct. There was a flush of blackgrass early in the month and time for two stale seedbeds during the autumn, which will help,” he says.

The wheat area received Liberator (flufenacet+ diflufenican) + Defy (prosulfocarb) pre-emergence, but he’s concerned that the dry weather might mean residuals won’t perform to their best this season. “It’s been a challenging autumn for establishment, seedbed conditions weren’t ideal and the lack of moisture may mean I come back and top up the residual in some areas.”

Ben will target any top-up Liberator on the cleaner land so that it stays clean, but in places where the blackgrass problem is more serious, he’s taken the decision not to use a top-up because the land is likely to go into a two-year grass ley or lucerne to regain control of the situation.

He’s also prepared to experiment to achieve the best blackgrass control. Last season he used hybrid winter barley because others had reported better control, but it didn’t work in his case. “They said that the vigour would smother out blackgrass, but I don’t fully agree, the canopy was thick but the blackgrass was still there plus the gross margin on conventional barley is better so this year I’ve gone back to all conventional.”

For cultivation, the big change has been a move to lower disturbance and direct drilling. “I think the one pass cultivator was probably the worst decision we made for blackgrass control, so we have sold that on and bought a direct drill.

“The direct drill is not the ‘silver bullet’ but it certainly helps to keep the focus on managing the top couple of centimetres so that weed seeds aren’t being mixed through the soil profile, plus this season I’ve noticed far more worms. In addition, the reduced workload means we can do some contract direct drilling for other farms.”

He uses a subsoiler to sort out compaction – usually on headlands and in tramlines – but has made adjustments to reduce disturbance. “We’ve fitted discs to open the soil surface slightly before the leg moves through and changed to lower disturbance wings to help.

“We also have some very shallow discs that we run at 20–40mm to level the soil and mix in trash, it’s not used on all the land but it’s especially useful for incorporating muck from the cows.”

Red means stop

The right crop sown properly can out-compete spring-emerging blackgrass, but the wrong crop or cultivation choice could exacerbate problems. “Spring cropping alone won’t solve blackgrass problems”, says Hutchinsons technical manager Dick Neale.

Tenant farmer and Hutchinsons agronomist Simon Wilcox took on a 165ha County Council farm last Oct at Warboys in Cambs, and inherited fields with high populations of herbicide-resistant blackgrass. Spring cropping is central to controlling the problem, accounting for almost half the rotation, alongside other cultural and chemical options, he explains.

At Hutchinsons Regional Technology Centre at Warboys, Dick Neale and Simon Wilcox are using spring crops to tackle the blackgrass problem.

“The starting point at Warboys is to assess weed pressure and categorise fields using a traffic light system of red (significant levels of blackgrass present), green (clean) or amber (seed bank largely confined to soil with limited seed return).

“I take a zero-tolerance approach, so it’s very clear cut; fields are either red or green,” says Simon. “Anything red goes straight into spring barley, regardless of rotation, as this is by far the most competitive spring crop. The worst fields will go into a second year of spring barley.”

RGT Planet was sown last season, but he favours Laureate next spring due to its wider range of end markets (brewing and distilling) and slightly improved rust scores. Looking at other spring crops, beans are the least competitive against blackgrass and need sowing relatively early to maximise yield, so should be reserved for “green” fields, advises Dick.

“Spring wheat is an option, but is less competitive than spring barley and should only be sown on ‘amber’ or ‘green’ fields.”

Peas or linseed are other options for “amber” situations as they can be sown slightly later than beans, allowing time to spray off any spring blackgrass flush before drilling. But they lack barley’s competitiveness and have more limited in-crop chemical options.

Minimising soil disturbance is vital to keep blackgrass within a “kill zone” (the top 50mm of soil) and avoid bringing up old seed. Land destined for spring cropping should be prepared in autumn, so the first and only spring cultivation is the drill. At Warboys, the traditional plough-based system has been replaced with surface tillage using a Cousins Surface cultivator and low-disturbance drill.

“Stubble is left until Sept so the sun can dry out any blackgrass seed on the surface which reduces its viability. We then cultivate to no more than 5cm deep to stimulate blackgrass germination and break-up residues,” says Simon.

“If conditions allow, we’ll follow with a second pass at an angle 3-4 weeks later, after the initial flush, often using this cultivation to kill the weed rather than glyphosate initially.”

Blackgrass flushes are sprayed-off with 720g/ha glyphosate before the three-leaf stage, with the last spray applied around mid-Nov. “There’s not much winter blackgrass growth, so we leave fields until the weather window in Feb or Mar allows a final glyphosate before going straight in with the drill.

“We don’t wait for spring blackgrass flushes as these normally occur in Apr. With barley, it’s better to get the crop up and away ahead of blackgrass emergence to maximise the competitive effects.”

About 5 for 5

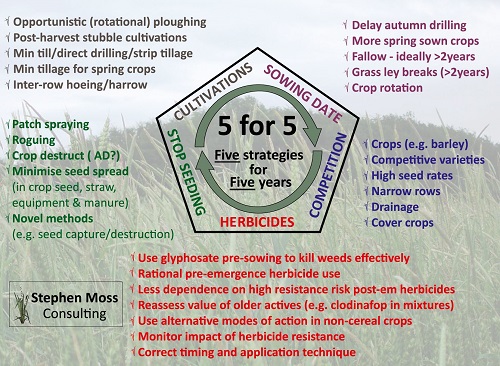

The ‘5 control strategies for 5 years’ has been put together by blackgrass expert, Dr Stephen Moss, and is based on his years of research. The initiative aims to encourage growers to adopt comprehensive strategies to tackle blackgrass by maintaining a planned, integrated approach at an individual field level for at least five years.