Magnesium is easily overlooked, in spite of its crucial roles in plant nutrition, and this may have much to do with available sources, both in the soil and on the market. CPM travels to Germany on a quest to address this.

There’s a poor understanding of the function and importance of magnesium.

By Tom Allen-Stevens

From the moment you step into the buildings above the K+S Kali mine at Neuhof-Ellers, you can feel the power of the plant driving the unit.

In front of you is the headframe of the mine’s shaft, the cables spinning furiously as they pull another 25t ore skip to the surface. This whooshes past at 24m/s and disappears to the top of the headframe. A solid clank signals it’s deposited its load of crude salt, and it plunges down again on the 1000m journey to the drift from where the minerals are extracted.

The group standing at the headframe of the mine is a delegation from across Europe that has come together to explore the value of the minerals extracted, and in particular magnesium – a somewhat neglected crop nutrient, according to Dr Rolf Härdter, of K+S’ agronomy and advisory unit.

“Erroneously, the industry talks of nitrogen, phosphorous and potassium as macronutrients and then calcium, magnesium and sulphur as secondary nutrients. But Mg and S are needed by plants in the same order of magnitude as P,” he says.

The mine at Neuhof-Ellers is one of seven in Germany operated by K+S Kali, this being its southernmost production plant, about 100km east of Frankfurt. It’s also a key source of kieserite, a mineral valued for its high magnesium and sulphur content, that comes to the surface along with the potash salts.

Around 500-600t/hr of crude salt is carried along 36km of conveyors and processed, producing 60-70t/hr of potash and 80-90t/hr of kieserite, with the remaining rock salt adding around 400t/hr to the vast ‘Mount Kali’ that overshadows the plant. This results in a factory output of around 1.3M tonnes per year across six product lines, with around 550,000t of this sold as kieserite-containing fertilisers.

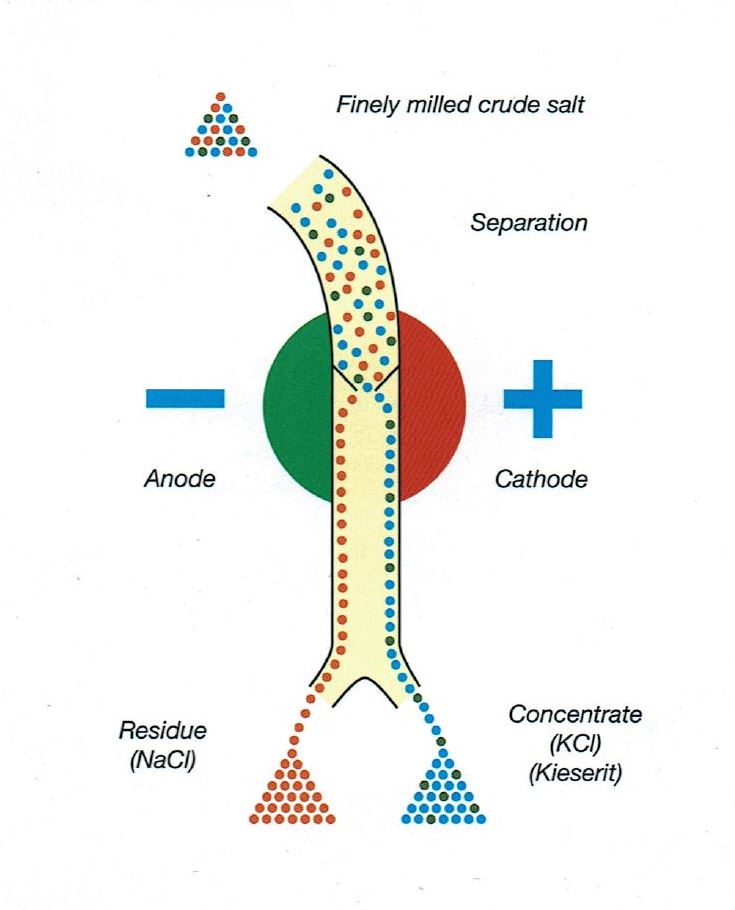

The electrostatic process through which the kieserite is extracted from the crude salt.

The process through which the kieserite is separated is fairly ingenious. A dry, patented process, the finely milled crude salt particles are treated in such a way they naturally become electrically charged. They then free-fall past electrodes, that separates them and gives the process its name – Esta (ElectroSTAtic). Sylvite (KCl) and kieserite (MgSO4) are drawn towards the cathode.

Further processing then produces the fertiliser Esta Kieserit, sold in its fine form (27% MgO, 55% SO3) for producing complex compound fertilisers and as a granular material (25% MgO, 50% SO3) for use as a straight or for blending. Made only in Germany, Kieserit is fully water-soluble, so it’s immediately available to the plant, and its natural production process means even organic farmers can apply it.

So why does magnesium remain a neglected nutrient? “In the hierarchy of yield effects, it’s not as dramatic as N, P and K,” notes Frontier nutrition specialist Edward Downing, one of the UK representatives on the study tour. “But it’s nonetheless a macronutrient and the crop takes it up in kg/ha. There’s a poor understanding of the function and importance of Mg – you’ll find it at the centre of every chlorophyll molecule.”

In fact, there are six processes Rolf spells out where Mg plays a “crucial” role:

- Photosynthesis – it’s needed to turn light energy into yield. Mg is the central atom of the chlorophyll molecule.

- Synthesis, transport and storage of important plant substances such as carbohydrates, proteins and fats.

- Root growth, which means Mg affects water and nutrient uptake from the soil.

- Stress tolerance, such as heat/radiation stress.

- The function of a number of enzymes that regulate metabolic processes.

- RNA synthesis and therefore the translation of genetic information into proteins.

“If a crop is inadequately supplied with Mg, these processes don’t happen, and in severe cases you see the cell damage and death signalled by yellowing or discolouration of leaves. But long before you see symptoms, these processes are shutting down,” notes Rolf.

In acidic soil conditions – something that affects the majority of European soils – the saturation of aluminium increases, he says, which impairs root growth. “But soils with an adequate Mg level will combat the negative effect of Al.”

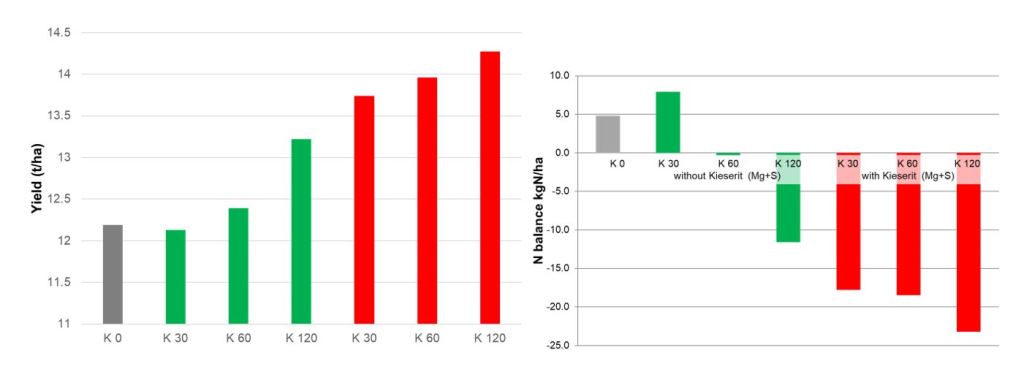

Trials carried out in N Germany have shown Mg can also improve nitrogen use efficiency (see charts below). More nitrogen was taken up by a crop of winter barley where kieserite was applied, resulting in a 1t/ha yield advantage.

Nitrogen use efficiency in barley

Source: K+S trials, Ostenfeld, 2015; Preceding crop: winter wheat; cv KWS Meridian; Nmin 31kgN/ha; Applied N 190kgN/ha.

In the UK, there’s been little recent research that would make much difference to the recommendations on Mg advised in RB209, notes Edward. “It’s therefore important to know your soil indices and crop offtake before deciding whether to apply any product.”

This is usually expressed as the oxide MgO, with combinable crops typically taking up 30-60kg MgO/ha at peak. “Cereals are relatively tolerant to low Mg levels, with even a 10t/ha crop removing not much more than 20kg MgO/ha, and applications are usually only justified when Mg indices are close to or at 0. Oilseeds are more responsive, and a 4.5t/ha crop will take up around 50-60kg MgO/ha, so it’s worth making applications at index 0 and 1.”

Root crops are very much more responsive, with sugar beet typically removing 0.5kg/ha MgO for each t/ha of yield. “Applications to both sugar beet and potatoes are justified at indices of a low 2 and below,” he advises.

For soil applications, the usual recommendations are 150kg MgO/ha at soil index 0 and 75kg MgO/ha at index 1 for responsive crops. For a non-root crop rotation, 50-100kg MgO/ha every three to four years is recommended at index 0.

“The reason not much is applied to cereals is that levels tend to be corrected in other crops, however smaller, but more regular applications may be a better strategy to cover crop removal and provide sulphur to these crops. Mg is water-soluble, but doesn’t usually leach, as long as you have reasonable clay content in your soil.”

As kieserite delivers both magnesium and sulphur it provides most value where the crop is also utilising the S content. “That way the cost is spread over both valuable nutrients. You can use it all year round, but it’s best applied in spring to make use of the S, so an early application to oilseed rape fits perfectly.”

If applying at a variable rate following nutrient mapping, remember the rate will vary for both Mg and S. “More and more growers are variably applying nutrients and Kieserit is a good choice for Mg here. I’d suggest applying a minimum rate, though, to ensure the S rate is correct, with extra applied in low areas as required. It’s a good idea to talk to your Soyl agent or agronomist about what’ll work best for your farm,” advises Edward.

According to advice from the Potash Development Association (PDA), soil usually contains between 0.05-0.5% total Mg but only a small proportion is in exchangeable forms available for plant uptake. Like K, available Mg is in the soil solution, held on the exchange sites of clays and organic matter. But unlike K, Mg doesn’t move from its non-exchangeable to exchangeable forms easily.

Although the magnesium content of fertilisers is expressed as MgO, this is just a convention, and it’s usually applied in sulphate, carbonate, oxide or, occasionally, nitrate forms or in mixtures of these. Magnesium sulphate is readily soluble and quick acting whether applied to soil as kieserite or kainit or as a foliar spray.

Another common source of magnesium is dolomitic or magnesian limestone, which typically contains around 20% MgO in the carbonate form and is commonly used in some areas to correct acidic soils. Here, regular use over many years has increased soil Mg to very high levels, and this can cause concern. But a high soil Mg level can also occur naturally, due to the soil’s parent material.

High Mg indices don’t damage crop growth, but may hinder the uptake of K (see panel on pxx). So if soil Mg is at index 4 or above, PDA advice is to switch to calcitic limes in these situations.

Livestock and other manures also contain Mg and a typical application of 35t/ha of cattle FYM will provide around 60-65kg MgO/ha. Nutrient content of manures can vary, however, so PDA advises a laboratory analysis is carried out.

There are other magnesium options, explains Alan Gray from Origin fertilisers. “Calcined magnesite is a cheaper form of magnesium, typically around 83% MgO, which is formed from burning off the calcium carbonate from dolomite, but it has low solubility and is less available at high pH. It comes in a powdered form too, so it’s more difficult to spread accurately.”

Magnesium sulphate is also available in lower concentrations in its natural form as Magnesia-Kainit (11% K2O, 5%MgO, 27% Na2O, 10% SO3, 43%Cl) and other products such as Korn-Kali (40% K2O, 6%MgO, 4% Na2O, 12% SO3) and Polysulphate (14% K2O, 6%MgO, 17% CaO, 48% SO3).

“Blends are a good way to get the constituents you’re looking for,” continues Alan. “These can be tailored to suit the situation, but a typical NPK blend using kieserite might be 13:13:13 with 6% MgO and 12% SO3.”

He favours blends based on Magnesia-Kainit for sugar beet, to take advantage of the higher Na content. “If the crop doesn’t require N, such as for pulses, a blend based on Korn-Kali might be a good option to go for – you can work the same analysis in a number of different ways with blends.”

K+S is the only producer of kieserite, notes Jerry McHoul of K+S UK and Eire. “Of around 6M tonnes of product we supply, about half are straight potash while the rest contain Mg.

“There’s also Patentkali (30% K2O, 10%MgO, 42.5% SO3) based on sulphate of potash that suits potato and vegetable growers. For processing potatoes, it’s been found to help reduce blackspot bruising and improve quality and storage properties.”

All K+S products spread well across a 36m bout width, he adds. “They also spread well with ammonium nitrate or NPK blends, because the size of the granules is well matched.”

Struvite excitement

Trials in maize using placed diammonium phosphate (DAP) and Esta Kieserit at planting have produced impressive results suggesting struvite (magnesium ammonium phosphate) may be the cause.

Used in high-value crops, struvite improves the utilisation of nitrogen and phosphate, leading to yield improvements and reduced losses. But it’s rarely cost effective on broad-acre crops.

“We know from lab studies that if DAP and Esta Kieserit are placed next to each other, struvite can be naturally formed,” notes Rolf Härdter. “We think the same may be happening when the two products are placed in close proximity at planting within the crop root zone.”

The K+S trials showed remarkable improvements in maize establishment through this technique, which wasn’t seen when either was used separately. “The N is often nitrified and the P can be quickly locked up. The addition of kieserite appears to keep both available,” he surmises.

“It needs further investigation, but we think with this method, we can improve the efficiency of both organic and inorganic nutrient sources,” concludes Rolf.

Watch the magnesium balance

Even when soil Mg levels appear to be correct, uptake by plants may be compromised. “There’s a difference in the way plants take up K and Mg,” explains Rolf Härdter.

“K is taken up in a preferred way, while Mg is drawn from the soil solution more passively. That means in certain situations, such as peak K demand, Mg may be left behind.”

Release of the two nutrients into the soil solution can be slow and is affected by a complex of processes. Jerry McHoul believes relative concentrations play a part. “Where the ratio of exchangeable K is less than half that of Mg, potash supply can be limited and conversely when K levels are above six times that of Mg, supply of Mg can be a problem,” he says.

Apart from grassland situations, where imbalances may bring about hypomagnesemia, Edward Downing doesn’t believe it’s too much of a concern. “Uptake can be affected if there are nutrient imbalances, but that tends only to happen when one index gets very high – above index 4.”

Where there are known problems with Mg uptake or deficiencies have been experienced in the past, he recommends using a foliar Mg product, such as Epsom salts or Bittersalz, on wheat at the T2 and T3 spray timing. “If you have any limitations with photosynthesis, that will hit yield and quality, so why would you not want to consider a foliar spray? The same goes for OSR at stem extension.”