Spring beans have slotted into the rotation for some time for a Herts arable business. CPM visits to find out how the crop has now become the mainstay break crop.

Grow a decent sample at 4.5t/ha and you’ll make money.

By Tom Allen-Stevens

Suggest that Will Streeter has “quite a good” crop of spring beans and you’re smartly corrected.

“It’s not quite a good crop. It’s an exceptional crop,” he replies. And he has every reason to be pleased with his Fuego spring beans that stretch away in uniform, band-sown rows over the field of Hanslope clay. Despite the dry spring, they’re promising real potential, with minimal weevil damage and not a sign of disease.

Despite the dry spring, the Fuego spring beans are promising real potential, with minimal weevil damage and not a sign of disease.

This is just as well, as spring beans now form the main break crop for TS Arable, farming a total of around 2000ha, based at Harps Farm near Bishops Stortford, Herts. The crop follows a second winter wheat in a five-course rotation.

“Historically, we’ve always grown around 400ha of spring beans. It’s winter oilseed rape that we’re questioning,” says Will Streeter.

Dry at establishment

Just 32ha of the brassica crop remain in the ground after most of it failed to establish last autumn. “We’d already taken the decision to move out of OSR and drilled just 150ha. But it was so dry after establishment, very little emerged. Just one block had enough moisture to get away, but every critter’s had a go at it, and if it yields one tonne for every ha we have, it’ll have done well.”

The business has over 1000ha of winter wheat distributed across nine individual farms. These are managed in a partnership comprising brothers Tom and Will Streeter and long-time family friend Dave Tinney. With the OSR area dropping back, Will Streeter, responsible for the day-to-day management of the arable concern, has been putting more spring barley, spring wheat and winter oats into the rotation, alongside 155ha of winter barley.

“We used to grow 800ha of OSR, but one day I worked out just how much of the crop you can typically expect to lose. By the time dry conditions, cabbage stem flea beetle, pigeons and rabbits have taken their portion of the crop, there’s not usually a lot to take through the spring,” he says.

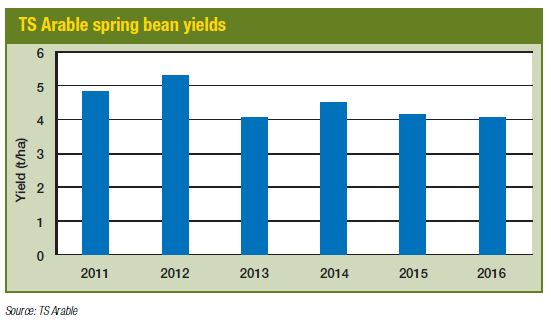

Spring beans by contrast have put in a much more consistent performance, producing an average 4.5t/ha over the past five years (see chart on pxx).

Another point in favour of spring beans is the opportunity for blackgrass control. “Having blackgrass is like being an alcoholic – you have to put your hand up and admit you’re hooked on the herbicides you’ve relied on to control it. The choice of chemistry in winter crops is increasingly restricted, but we’ve had fantastic control of blackgrass through spring cropping for the past ten years.”

A critical part of this has been rotational ploughing, continues Will Streeter. “When we set up TS Arable, the previous generation said we needed to keep the plough in the rotation. Our soils are consistent, but moisture retention is often a challenge, and ploughing for winter crops can be a problem. So spring beans and ploughing just fell together and over the past five years we’ve focused on getting the ploughing right – as reliance on chemistry has dropped off, grassweed control has come down to rotation and quality of the seedbed.

“It helps that we have staff who enjoy ploughing and take pride in it. You have to know what you want to achieve from the seedbed and then work back from there. For spring beans, we want a good level finish that we don’t want to move in spring.”

So as soon as the combine leaves the field, the tramlines are busted out if necessary with a three-leg Simba Flatlift. Then one of two Kverneland ploughs are put through, lugged by a Challenger MT765B or John Deere 8370RT. “We plough early and let it bake out, then run a secondary cultivator over the ground to get a level finish but not one that’s too fine. It should have plenty of air and clods in it to take the weather and drain well over winter,” he says.

Patience is the key in spring. “We’ll often drill a month later than others. We wait for the ground to dry and warm up – if you put seed into cold soil, you lose the vigour.”

An 8m Horsch Sprinter drill band-sows the seed to a 50mm depth in 320mm rows. Drilled at a steady 12km/h, the band-sowing ensures minimum soil disturbance and a seed rate of 250-300kg/ha aims for a target population of 50-55 plants/m². Seed is generally farm-saved, and Will Streeter’s view on varieties is that they all perform within 5% of each other. This means field and soil management form the focus, rather than variety choice.

Precision farming

“We’ve just started variable-rate seeding,” he says. “Precision farming isn’t something we’ve gone out of our way to invest in, but the kit comes as standard on most new purchases now. We’ve been gathering variable-rate information from our crops for about six years, and now we’re starting to make use of it.

“So with the help of IPF, we zoned all the fields and used this as the basis of variable-rate seeding. The aim is to achieve optimum crop population, so push the better land a little harder to achieve an improved yield.”

Phosphate and potash are also maintained through variable-rate applications, although 10-15,000t per year of biosolids spread across the farms in front of the other break crop in the five-year rotation contribute most to replenishing indices.

Glyphosate is the main weapon against grassweeds, reveals AICC agronomist Jamie Mackay, who advises TS Arable on crop protection. “The crucial application is the one in March just before drilling the crop, and I wouldn’t be against mixing glyphosate with the pre-emergence herbicide. If you’re not inverting the soil in front of beans, an application in Oct or Nov avoids a build-up of grassweeds.”

A post-em application of Laser (cycloxydim) is still effective on the farm’s reasonably susceptible blackgrass, he reports, while broadleaf weeds get a pre-em hit of Nirvana (imazamox+ pendimethalin). “This doesn’t work brilliantly in a dry season, however, and if expecting cleavers, I’d add Centium (clomazone).”

Loose lumpy soil

Pea and bean weevil pressure has been moderate this year he reports. “I’d expect it to hit the earlier crops harder, in any case, and the loose lumpy soil Will Streeter leaves tends to waylay the pest.”

Downy mildew is the main disease threat, while bean rust can also be a problem. “For downy mildew, control is pretty much down to SL 567A (metalaxyl-M). It’s expensive, but we’re tied to it,” notes Jamie MacKay.

One spray programme to get right is for bruchid beetle control, adds Will Streeter – usually two pyrethroid applications are necessary, made in June. “Logistically this can be a challenge and getting the timing right can be difficult. We use the BruchidCast service as a guide.” (see panel on pxx).

At desiccation, the preferred option is glyphosate, over diquat, he continues (except for crop grown for seed) and this adds to the weed control. “We also use Pod-Stik. It costs an extra £10/ha, but it does a good job of keeping the pods together until they’re safely inside the combine. Hot, midday temperatures during harvest can result in a very brittle crop, so on our scale, it’s a valuable treatment that keeps the combine running.”

Good storage facilities help with beans, notes Will Streeter – the business has 10,000t of on-farm storage, all of which has on-floor drying. “A wet bean crop is very difficult to dry. You need plenty of air movement and not too much heat, so we’ll condition it carefully on either side of our new 1200t store and move it to a longer-term store once it’s reached the right spec. To achieve the premium on beans, you have to look after the crop.”

While beans provide an ideal entry for the following wheat crop, it’s the contribution they make to the rotation Will Streeter values most. “We have blackgrass, but because of spring cropping and ploughing we don’t have a bad blackgrass problem. Last autumn we spent £40/ha on pre-em sprays in the wheat, and most fields didn’t receive a post-em blackgrass spray – that’s genuinely down to the spring beans in the rotation.”

Strong prospects for beans despite market dip

There are three basic elements to get right for those looking to make a decent return from spring beans, according to Chris Collings of Harlow Agricultural Merchants (HAM), to whom Will Streeter sells his bean crop.

“To get the human consumption premium, it must be the right size, which comes largely down to variety. You should aim for less than 2-3% bruchid damage, and generally most growers need a two or three-spray programme to achieve that. And you must avoid staining, which means combining at the right time and getting the desiccation right,” he advises.

Based at Bishops Stortford, HAM trades around 35,000t of beans every year with two thirds of this going for human consumption. “North Africa is the biggest market, with most shipments leaving farm and going straight on the boat. A small proportion may be processed in the UK, bagged and containerised, but a good sample is always essential.”

The premium the crop can command has come away from the highs of up to £100/t above feed wheat, with £5-35/t more realistic, he says. “Bean prices follow wheat. There’s good demand for the crop, and this increases year on year in Egypt, for example. In the UK, the area grown has increased as it’s a crop that contributes to your Ecological Focus Area, but it’s not that that’s affected the market,” he notes.

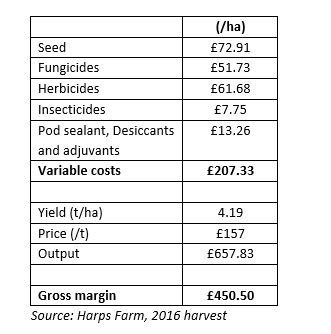

“The Australian crop always trades at a premium to UK, with 0% bruchid damage, and growers had four times their expected yields last year, putting the crop into markets it usually wouldn’t influence. There’s growing competition from Eastern Europe, but it remains a market with strong prospects – grow a decent sample at 4.5t/ha and you’ll make money.”

Time to spray for bruchid beetle

Bruchid beetles have been active in field bean crops for some time, according to PGRO, particularly winter beans that were flowering by the start of June.

“At that point, winter beans were at or almost at the first-pod formation stage, with pods forming inside flowers on bottom trusses. Insecticide sprays should be applied when the temperature threshold has been reached and around 50% of pods on bottom trusses are 2cm long,” advises Becky Ward of PGRO.

The Syngenta BruchidCast forecasting service (www.syngenta.co.uk/bruchidcast) gives guidance here, she notes, and predicts when the critical temperature threshold of 20°C for two consecutive days has been reached.

“To avoid risk to foraging bees, spraying should be carried out very late in the evening or at night time,” she adds.

Aphid populations are increasing following warm weather across the UK. For flowering crops the thresholds for treatment are 15% plant colonisation in vining peas, 20% in combining peas and 10% in field beans.

“Updates on suction trap catches and activity of crop aphid species can be found in the summaries provided by AHDB on the PGRO website,” says Becky Ward. “Information in the AHDB Aphid News bulletins helps growers optimise the use of insecticides, time treatments better and reduce harm to beneficial insects. This will also lower the risk of selection for insecticide resistance by reducing unnecessary or wrongly timed sprays.”

Spring beans: how the finances stack up

Farm facts

TS Arable, Harps Farm, Great Hallingbury, Bishops Stortford, Herts

- Farmed area: 2000ha

- Cropping: 1170ha winter wheat (Solstice, Skyfall, Zulu, KWS Siskin, JB Diego, Costello, KWS Santiago, Gator); 410ha spring beans (Fuego, Fanfare); 155ha winter barley (Volume, Bazooka); 130ha winter oats (Mascari); 62ha spring barley (Propino); 42ha spring wheat (Mulika); 32ha winter OSR (Elgar)

- Soils: Hanslope series clay

- Mainline tractors: Challenger MT765B; John Deere 8370RT; JD 7260R; JD 6215R; 2x JD 7810

- Combines: Claas Lexion 780 with 12m header; Lexion 760 with 10m header

- Sprayers: Chafer Multidrive 5000 litre with 24m booms; Chafer Sentry 6000 litre

- Drills: 8m Horsch Sprinter; 6m Accord Evo Drill

- Ploughs: Kverneland 9f and 7f

- Cultivation: 6m Horsch Terrano; 6.5m Väderstad Rexius Twin; 7.5m Simba Unipress; 6.5m Väderstad NZ; 4m Gregoire Besson subsoiler with Stocks seeder; 12.4m Cousins rolls

- Staff: Four full-time plus Will Streeter and extra help at harvest.