Spring barley has been part of the cropping mix for the past five years on a Shropshire farm. CPM visits to find out how on-farm trials are helping develop a successful approach to how it’s grown.

It’s part of learning to do things differently.

By Tom Allen-Stevens

The bright green lines of Propino direct-drilled spring barley stand out in the sunshine against the dying cover crop residue. The crop appears to have established well into Andrew Williamson’s silty clay loam, with an even germination and barely a patch across the field betraying the limitations of the current parched conditions.

But Andrew’s not altogether happy. He takes a penknife and prises a few seedlings from their well sealed slot. “It may look a good crop, but we’re struggling to get the seed drilled to a consistent depth. You have to give spring barley every chance to perform as it has such a narrow season, particularly when it turns dry.”

The crop has formed part of the rotation for the past five years across the 320ha of undulating land at Upper Overton Farm, near Bridgnorth, Shrops. A cropping mix that previously included wheat, oats and oilseed rape – all autumn-sown – now brings in spring barley and beans, extending the break between OSR and offering an opportunity to tackle blackgrass.

“Historically, all crops were autumn-sown, but I’ve seen how grassweeds can take over on many farms and trial sites and wanted to put in cultural measures that would avoid that happening here. The biggest effect is to delay drilling or spring cropping. You rarely get a chance to establish a crop at the end of October on this land, so spring crops are now part of the mix.”

Andrew’s a keen advocate of on-farm trials to see what works within his own conditions and farming system. From the start, he’s also been one of the 50 BASF Real Results farmers carrying out tramline trials with the latest fungicide chemistry and putting the results through a fair degree of scientific scrutiny to ensure a result that’s ‘real’.

As with his autumn-sown crops, practices he applies to his spring barley get the on-farm trial treatment. So when a difficult autumn in 2019 resulted in no winter wheat at all drilled across the farm, the Real Results trial was switched to his spring barley.

It forms part of a close scrutiny he applies to the crop to improve prospects, destined for breweries at nearby Burton-on-Trent. “We’re growing Propino because it’s the variety maltsters want – we don’t want to give them any excuse for rejections. Having said that, we can struggle to achieve the correct spec – last year around half the crop had a grain N that was too high.”

Land going into spring barley is largely decided by its blackgrass burden. “Fields coming out of a dirty wheat crop are the ones we’ll choose. Blackgrass isn’t a problem, but we don’t want it to become one, so we have a policy of zero seed return.”

A cover crop is sown soon after harvest. “We’ll establish this before the end of August and typically include vetch and spring beans, phacelia also works well. We avoid brassicas to reduce the risk of club root – OSR is our second most profitable crop. Also we’ll avoid cereals in the cover crop before a cereal.

“But the greatest challenge with cover crops is getting the date right to drill them. Too late and there’s no point growing buckwheat, for example, and we don’t want too big a canopy as that delays the soil drying out in spring.”

Sheep come in from a local farm to graze off the green cover from the end of December, but Andrew sounds a note of caution. “Sheep grazing needs close management – if they’re not moved on early enough, you suffer compaction. Ideally you’d strip graze and fence back.

“We’ll apply glyphosate pre-drilling and ideally wouldn’t spray a pre-emergence herbicide – I find that checks the crop growth which can do more harm than good in terms of grassweed competitiveness,” he notes.

Around 70-80% of the farm is now direct drilled with a 4m Sky Easy Drill. Andrew’s conscious that there’s blackgrass seed lurking in the soil he doesn’t want to wake up, and the drill delivers the establishment with minimum disturbance he’s looking for. But the inconsistent sowing depth is a concern.

“We drill at a variable rate of 180-270kg/ha, delivering 300-450 seeds/m², and with the variance in our soil, it’s important for an even germination to match conditions to crop requirements. There’s no evidence the crop is suffering from being drilled at an inconsistent depth, but you can see the seedlings develop roots at a slightly different pace, and that may affect how they take up nutrients in the early stages.”

Andrew delivers about 40% of the crop’s nitrogen requirement through the drill, with 30% broadcast before drilling and the balance applied as soon as the rows are visible, all with an SO₃ content. “We apply around 130-140kgN/ha total, looking primarily to achieve the yield, and hoping this will bring the right grain N for malting,” he notes.

“The barley also receives 20-30 l/ha total of Liquid Boost carbon fertiliser, applied across all spray applications. It gives the plant a carbon source and I think it helps soften the effect of any chemistry applied.”

Keeping barley stress-free is important for ensuring ramularia doesn’t develop, he notes. This has become all the more important with the loss of chlorothalonil. “We probably relied a lot on CTL without really being aware of it,” he comments.

“On wheat, it gave us flexibility at the start of the season, and going forward we’ll be looking at making the T1 and T2 sprays more robust. The extra protection from CTL also helped if spray application timings slipped, although I’d hope we have the capacity to stick to the correct timings.”

Andrew’s now looking at the early season sprays in a new light, however, having taken part in variable rate trials of Caryx (mepiquat chloride+ metconazole) in his OSR. Across three tramlines, he’s been comparing results of a flat rate sprayed at green bud stage, against none applied and against a variable rate decided through xarvio Field Manager. This uses satellite-derived biomass data to generate variable rate maps with field-zone specific dosing of crop protection and PGRs.

“I’m not convinced of the crop protection benefits of variable rate applications, but I do think there’s scope to tailor PGRs to crop growth, and the T0 application could be an ideal timing,” he says.

“It’s part of learning to do things differently. Just as with grassweeds that prompted us to look at spring cropping, it’s important to develop a crop production system that adapts to the tools and techniques you have available. Losing products such as CTL and neonicotinoids brings challenges for issues such as ramularia, BYDV and cabbage stem flea beetle. We’re moving to a new way of farming, and the best way to adapt is to trial the new tools available on your own farm under your own specific conditions,” Andrew concludes.

Step-up in performance is a Real Result

Winterburn is typical of the fields at Upper Overton Farm – a silty clay loam with a fair degree of variability. This makes it a job for Andrew to assess how a new product or technique he’s trying actually performs, which is where Agronomics steps in – it’s a method of analysis tramline-trial results that strips out a lot of the variation attributable to background factors.

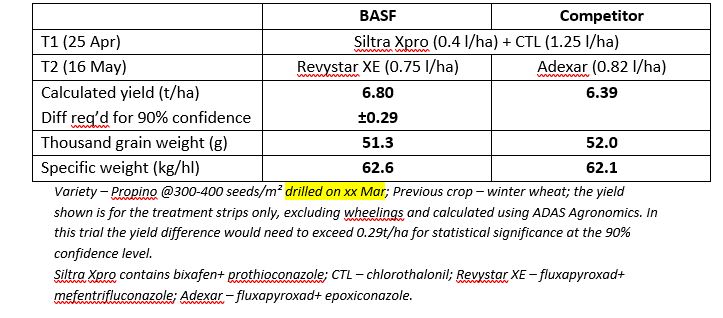

With no wheat drilled in autumn 2019, the spring barley crop was chosen for the 2020 Real Results trial, he explains. “Adexar has become our farm standard T2 spray application on spring barley. With epoxiconazole in its use-up period, I’m keen to see if Revystar XE offers a step-up in performance.”

Local BASF agronomy manager David Griffiths has arrived at the farm to assess the results of Andrew’s trial. “The focus with Revystar has been very much on wheat, but we’re keen to develop best practice for its use with spring barley,” he explains.

“We already know Xemium has key strengths in barley, reducing brackling for example. AHDB fungicide-performance trials identify it giving better control of rhynchosporium than prothioconazole and shown it’s highly effective as a protectant on net blotch. Revystar’s noted as performing ‘extremely well’ in 2019 ramularia trials, so it’s clearly no slouch.”

Andrew recalls his 2020 spring barley crop established well and “looked a decent crop” despite last year’s dry spring. “It coped with the weather as well as any crop. There wasn’t much disease and I’m not sure I could really pick out a difference in green leaf area (GLA),” he notes.

“The potential of the crop was hit hard just before harvest – some heavy rain included hail, and there were signs of brackling in the crop with heads on the floor. But I suspect this would have been worse without Xemium.”

Analysis by ADAS of NDVI images and the xarvio Powerzone map, that shows yield potential based on the field’s satellite history, shows the field had potential, particularly towards its eastern side. While NDVI images showed up no differences between treatments, an assessment of GLA on 25 June indicated a trend for a higher value for the Revystar treatment, although this wasn’t significant.

Harvest did reveal a significant difference, however. While the Adexar T2 delivered a yield of 6.39t/ha, Revystar pushed this up to 6.8t/ha. Importantly, these figures were derived from yield data analysed using Agronomics, excluding tramlines, wheelings and a low-yielding tramline on the west side of the field. This gave a result that is significant at the 90% confidence level, notes ADAS, and “in accordance with the trend for higher GLA”.

It’s the step-up in performance that Andrew was looking for, he confirms, and places Revystar as the new farm-standard T2 application for his crop. “I suspected I saw the difference as the combine was passing through, but couldn’t be sure. The results confirm it,” he says.

David believes the trial shows the strength of Agronomics. “It was a low disease year and difficult to tell the difference in GLA. It’s where a scientifically robust analysis pays dividends.”

This year, the trial has come back to wheat, and Andrew has more searching questions for Revystar. “I’m keen to know how Revystar will perform at the T1 timing where you haven’t applied a T0. Also, if the crop has received its T0, but you’ve cut back on the T1, the difference it’ll make at T2.

“The key aspect for me, though, is that Revystar is proving itself as a step-up in fungicide performance. We’ve seen that in wheat, and now it’s proven itself in barley. So the Real Results trials have given us more confidence in how we take our crop protection forward,” he notes.

Upper Overton Farm 2020 Real Results trials – Winterburn

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their fifth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk or scan the QR code to visit the all-new, cereal fungicide virtual trial, offering a 360° map to compare plots.