For over 17 years, South Oxfordshire farm manager Simon Beddows has put a number of variable-rate systems to the test across his highly varied soils. CPM visits to see how he’s getting on with xarvio Field Manager.

You walk across one of our fields and you can see how the growth varies.

By Tom Allen-Stevens

As Simon Beddows reflects on the cropping season that’s drawing to a close, it’s clear his life is dominated by managing variables.

“March was unusually cold, and we didn’t apply a T0 fungicide spray. April then headed towards being the driest on record and there was a frost nearly every single night. We had 90mm of rain in May and there was barely a day to spray, with another 90mm falling in June.”

All that considered, the crop of wheat he pulls the canopy back on looks in remarkably good shape. But then you could say Simon has spent most of his career mastering the art of managing the variables. Farm manager of Coppid Farming Enterprises, he’s responsible for 750ha of arable cropping based at Dunsden Green near Sonning Common, S Oxon.

With fields that dip and fold into steep undulations, he wrestles with no fewer than 17 different soil types, from clay caps, to chalk, to gravel, and “everything in between”, he says. “You can get the full range of soils in just one field.”

So for the past 17 years, he’s developed variable rate application (VRA) systems across the cropping that tailor inputs more closely to the situations he’s faced with. A keen advocate of on-farm trials, this has led him to join BASF’s Real Results Circle – 50 farmers carrying out tramline trials with the latest fungicide chemistry and putting the results through a fair degree of scientific scrutiny to ensure a result that’s ‘real’.

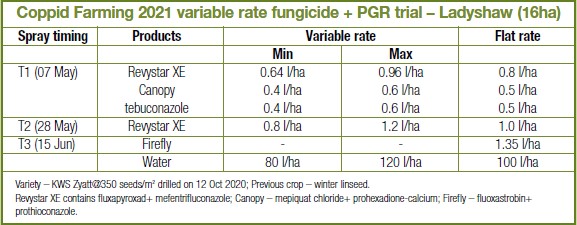

This year, Simon’s one of a number within the group who are not just putting the fungicide through its paces. His field trial has been specially set up to compare how Revystar XE and growth regulator fare when applied variably. The variable-rate applications themselves are managed through xarvio Field Manager, the crop optimisation tool from BASF Digital Farming.

“I was particularly keen to take part in the trial, both to see what xarvio’s like to use, and to apply some scientific scrutiny to variable-rate fungicide applications,” explains Simon. Louis Wells from xarvio, along with BASF local agronomy manager Jenny Lawes have arrived at the farm to review how the trial has gone and glean some of his experience.

For Simon, this is the latest stage in a progressive journey he’s made, which started off with varying phosphate and potash applications. “Standard testing in a W pattern showed our fields were around Index 2 for P and K. But when tested in a grid system, we found they actually varied from Index 1 to 4.5, so it made sense to put the fertiliser on only where it’s needed.”

Over the years, Simon has managed to even out the indices and reallocated applications of P and K by variably applying it. “The next step was to vary N, and as with the P and K, this wasn’t so much about saving fertiliser as evening the yields – the combine maps showed they varied from 5-11.5t/ha, with the average being around 8.5t/ha.”

He undertook tramline trials to confirm the results he was getting, comparing flat rate applications with varied, based on in-season crop biomass information supplied via satellite. Three years of trial results showed the yield in the variable rate N tramlines exceeded that where the flat rate had been applied by an average of 0.25-0.75t/ha. “Wherever we applied by variable rate, the yield benefit was at least 0.1t/ha, which more than paid for itself. It takes more management to achieve that, but you’re paid for the effort you put in,” he says.

A lot of this effort has been applied grappling with the precision-application kit itself. Simon has spent more than his fair share of downtime trying to get various bits of software talking to the hardware they’re supposed to link with. “We’ve settled on myJohnDeere’s telematics system now, not because it’s the best, but because it’s the least worse. It’s a real problem in precision farming that nothing joins up. They’re getting there, but there needs to be a better system.”

The focus of his attention currently is spray application, and it’s a Chafer Sentry 5000-litre trailed machine, fitted with a Müller ISOBUS system, that handles the variable-rate applications he makes to his crops. “The 30m boom is divided into ten sections, which is useful for auto shut-off, but you can’t vary the rate across the boom width, and that’s something worth noting if you’re going down the precision application route – the granularity of the system deciding your variable rate can be better than the machine actually applying it.”

The rate is varied through pressure, and Simon notes this is limited by the sprayer nozzles and what they can accurately apply. “Generally, I’ve found 20% up or down is the limit. Beyond that you compromise the spray pattern.”

The variable input he’s been pursuing has been growth regulator. “You walk across one of our fields and you can see how the growth varies. I’ve always believed that PGR knocks the yield in thinner areas of crop, but you can’t afford not to apply it where it’s growing well.”

So again, Simon’s carried out some thorough field testing and has found a yield benefit of up to 0.5t/ha from VRA which, given the cost of the PGRs themselves, is a fair return on investment, he points out.

The software platform he uses most for VRA, to generate maps, is MySOYL, part of Frontier’s MyFarm platform. He’s currently running xarvio along with a number of other packages. “They all essentially do the same, but slightly differently, and it would be personal preference as to which one you choose for a specific job,” he says.

“The advantage with xarvio is that it’s simple and easy to use to generate VRA maps. I’m familiar with the SOYL system which is more flexible. They offer more of a service, with the option that their staff will create the maps for you. But I generate my own, which I prefer, although it can be a more complicated job than it needs to be.

“Setting up zones in xarvio, on the other hand, is very intuitive, although you can only create one field at a time at present. Like other satellite-based services, the availability of the images in season is limited by cloud cover,” says Simon.

Louis notes that xarvio has been designed around a self-serve digital system, although on-line help is at hand from the xarvio support staff. “The Power Zone maps in xarvio, used to create management zones, are based on 15 years’ historic satellite images, and have been found to give a very accurate picture of crop biomass. But we are constantly improving in-season satellite images, with radar-based coverage that’s irrespective of cloud cover, due to be introduced soon.”

VRA is a particular strength of xarvio, Louis notes, with five years of trials across Europe showing a £30/ha benefit. “For both PGR and fungicides, there’s a greater need for protection where the crop is thicker. It also aids resistance management as dose is tailored closer to disease pressure. There are guards in the system that prevent a dose rate being applied outside those permitted by product labels.”

For Simon, a key benefit is that he can show he applies crop protection products more responsibly. “That’s not just about ticking the right box now – this sort of technology will be important to smooth regulatory approval for future products.

“What’s more, the products we have at the moment are good, but they’re costly – I only want to apply as much of them as I need. And the weather will only get more challenging – technology that helps find the right time to spray at the right rate will be increasingly valuable,” he adds.

Hopes raised for a VRA Real Result

The cold start to the season with barely any disease convinced Simon a T0 application wasn’t necessary for the KWS Zyatt in the trial field. “By the T1 timing, a bit of yellow rust had crept into the KWS Zyatt in other fields, but this one, following winter linseed, stayed clean. However, we added tebuconazole in the trial field in any case to bolster the rust protection,” he recalls.

In-season biomass maps from xarvio Field Manager were used as the basis for the trial maps for T1 and T2, with rates varied in the VRA areas by ±20%. Three sets of twin tramlines across the field provide the flat-rate comparison.

“Canopy PGR acts on the crop in two ways,” explains Jenny. “At T0 it’s beneficial for rooting, while it acts on the stem internode at T1. Thicker crops are much more vulnerable at this stage and more likely to put on faster growth, so it makes sense to apply the PGR variably.”

Despite the odd weather, Field Manager kept reasonable track of growth stages and timings, although Louis notes growers should continue to monitor crops and be guided by leaf layers. “If the growth stage drifts from what’s actually found in the field, you can create an observation in Field Manager to correct it,” he adds.

The cold weather meant the T1 was applied late with the T2 sprayed not long after. “Despite conditions turning wet, there was very little septoria, and latent disease testing confirmed this,” notes Simon.

There was no visible difference in the levels of disease in the crop, nor indications as to whether the VRA has done its job. But Simon knows to reserve judgement until the yield data’s in and has been analysed as part of Real Results using ADAS Agronomics, that accounts for in-field variability.

“The scientific rigour of Real Results is the key benefit of these trials, along with seeing how the latest technology performs in my own field conditions. But you also get to share the results with like-minded farmers in the group, so I’m looking forward to hearing how others have fared, too,” he says.

xarvio ASSISTs with biodiversity

Detailed environmental data has now been brought into xarvio. BASF Digital Farming has worked together with the UK Centre for Ecology and Hydrology to integrate the Centre’s ASSIST E-Planner tool within Field Manager.

The tie-up allows users to identify less productive areas, assess their suitability for a range of environmental management options and integrate this information with their seeding, nutrition and crop protection maps.

xarvio Field Manager itself was launched in the UK in Jan 2020. Its user base has more than doubled since summer 2020 to 2500, while it’s being used on more than 3M hectares of arable land across Europe.

It offers agronomic insights for crop production including VRA for fertiliser, seed and crop protection, with accurate field-specific prediction for disease, pests and lodging risk. This supports decisions on fungicides and PGRs in winter wheat, winter barley and now spring barley has been added. Prediction of pest risks is offered for OSR, while there’s field-specific automatic modelling of crop growth stages for all four crops.

Application maps from Field Manager can be sent and received wirelessly to and from the tractor terminal via MyJohnDeere and Agrirouter or via the new in-cab xarvio Connect box.

‘Buffer Zones’ is a new feature in development whereby application maps will automatically prevent nutrient being applied where risk of run-off and/or leaching is high.

‘Field Notes’ allow growers to accurately record, image, and pinpoint the location of issues, such as weeds, in any given field. xarvio has detailed in-season weather analysis to inform the best conditions to spray, or you can connect to your own arable weather station.

Packages start with Field Manager Basic available for free, with Premium costing £500/year.

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their fifth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to basfrealresults.co.uk to visit the all-new, cereal fungicide virtual trial, offering a 360° map to compare plots.