On-farm trials are allowing one Lincolnshire grower to apply a greater level of scrutiny to crop agronomy. CPM finds out.

The level of detail you receive in the reports is fantastic and raises your level of understanding.

By Tom Allen-Stevens

If there’s one aspect of crop agronomy that’ll show more value over the coming years it’ll be the detail behind what you see in the field, believes Alex Borthwick.

“You look at yield maps and you think there’s no difference, but drill into the detail and you find it. Going forward we’ll be required to ensure we have good evidence behind our agronomic decisions, and we’ll need it to ensure they’re the right ones for our business too,” he says.

Alex is agronomist for RM Cottingham, based at Hoehill Farm, Swinhope on the Lincs Wolds. His father, David, is manager of the 880ha farm, which has winter wheat, winter and spring barley and oilseed rape in the rotation, along with potatoes and sugar beet. “Dad’s been here for forty years, and it’s really useful having his experience – some new ideas turn out to be not so novel after all.”

Having trained as an accountant, Alex switched into agronomy, became BASIS-qualified and took on the farm agronomy in 2015. Keen to bring a level of scrutiny and detail into all aspects of the job, he has an active interest in on-farm trials.

“We have around three or four trials that take place on the farm every year. Most of these are small plot trials for various companies looking at herbicide treatments, and there are often one or two novel compounds involved in various stacks and sequences. I take a close interest in the different treatments and look at how we can tweak programmes over the farm to improve results.”

For the past three years, he’s also been one of the 50 BASF Real Results farmers carrying out tramline trials with the latest fungicide chemistry and putting the results through a fair degree of scientific scrutiny to ensure a result that’s ‘real’.

“It’s really valuable – the level of detail you receive in the reports is fantastic and raises your level of understanding. This is not just about efficacy or differences in green leaf area between treatments. The trial’s also entered into YEN (Yield Enhancement Network), so you get a full soil report and grain analysis, for example. This helps put the treatments into the context of the wider crop picture.

“A real positive has been the interaction with other farmers. They’re a fantastic group and there’s a willingness to share information and discuss common interests – it’s really opened my mind.”

One issue the farm has struggled with is blackgrass, he notes. “2013 was a wake-up call for us. We realised things had to change – rely less on the chemistry, think more strategically how this is used and bring in more cultural control options.”

Here it’s a combination of the little things with one or two more fundamental changes that are bringing blackgrass under control. Alex calls them “the icing on the cake” and include measures such as looking carefully at where pendimethalin and diflufenican are used, using contact chemistry in sequence in autumn, rather than in spring, and focusing on water rate and nozzle choice.

“A big step we’ve taken is to adopt later drilling, aiming not to establish a crop in bad blackgrass fields until mid October. While that’s caught us out over the past couple of seasons, there’s no doubt it’s helped the blackgrass control.”

This has been one of the factors that has moved on variety choice. KWS Siskin and KWS Extase currently make up the majority of the wheat area, with some of the Siskin on a C1 seed contract. RGT Saki and SY Insitor are also in the ground, along with Crusoe grown for its premium potential.

“For many years, JB Diego was the mainstay, and it was a fantastic variety. Septoria became the issue with it, though – although yellow rust is the main disease here, septoria is the one that’s harder to control and has informed our variety choice.

“The yield from Siskin has been phenomenal – it puts down a fantastic root system – and you just hope this is a variety that keeps its strengths for some time to come. There are higher yielding varieties – we tried KWS Kerrin which yielded well on some of our heavier ground – but it’s weak on septoria, so it’s risky,” says Alex.

“We look at varieties as a level of cultural control against disease. Yield performance of wheats hasn’t really moved on in recent years, but there’s no denying there’s stronger genetics against septoria. Meanwhile, the loss of chemistry such as chlorothalonil (CTL) and epoxiconazole is putting more pressure on the SDHIs, and all the time the septoria population is evolving.”

Alex is joined by local BASF agronomy manager Aliona Jones to review performance of the Real Results trials, who notes 2020 was a low disease year for septoria. “But there will still be iterations in the population. There hasn’t been much septoria pressure for the past few years, but my concern is that if we do get a bad year for the disease, it will be a very different prospect from the last time it was an issue,” she notes.

Alex has concerns, too, for other components in the fungicide armoury. “There’s a heavy reliance on prothioconazole across the spectrum of main fungicides used at key timings. What’s more, the loss of CTL will put a greater emphasis on the T1.”

Historically, the farm standard T0 application has been straight CTL, with Alex only adding a dose of azole, such as tebuconazole, if yellow rust shows up early on. With the wheat now drilled later and with better genetics, he’s considering dropping the T0 where there’s no sign of rust and working towards a more robust T1 spray.

“Folpet really doesn’t do much on septoria, so I don’t see the benefit in using it,” he continues. “Having seen how Revystar XE performs over the past two seasons, as well as seeing the trials results in Ireland, I can see that we’ll be making more use of this to strengthen the T1, as well as using it at the T2 timing, depending on how the season pans out.”

Aliona notes Revystar offers a fair degree of flexibility at both timings. “We’d recommend no lower than 0.75 l/ha at T1 with the standard dose being 1 l/ha. At the T2 timing, 1 l/ha achieves effective control while this should be increased to 1.2 l/ha in more testing situations.

“I expect many growers will make changes to their T0 strategy with the loss of CTL and much less epoxiconazole around this year too. Some with more disease-resistant varieties may consider dropping a T0 in favour of a more robust T1 then decide on the T2 strategy as the season unfolds. Another tactic may be to use tebuconazole with perhaps a bit of strobilurin at T0, a less robust T1, and then go strong on the T2. You’ve got the flexibility in Revystar, in terms of its curativity and longevity, to manage a variety of scenarios,” Aliona continues.

“But this year, we’re going to add digital tools to the Real Results trials.” Alex’ standard farm practice will be compared with timings decided by xarvio Field Manager, a disease support platform that uses local weather data and cropping information to deliver recommendations, based on calculated risk of disease prevalence.

“It uses powerful algorithms that have been ground-truthed and improved over many years and bases recommendations on how key pathogens will react to the specific weather and crop conditions,” explains Aliona. “It’ll never replace human intuition nor observation, but xarvio can ‘see’ in the crop what you can’t with the naked eye and works to a much higher level of detail over a wider area than an agronomist could.”

Alex has tried a very early version of xarvio and wasn’t impressed, but will be keeping an open mind. “I was frustrated by the lack of cropping options, but I understand the tool has really moved on in its usability. It’ll be interesting to see where my decisions differ from xarvio’s during the season,” he notes.

“There’s so much digital tech out there and there are issues to do with data ownership and compatibility with other datasets we hold that I’d like to see addressed. But going forward I can see that regulation will require our decisions to be increasingly evidence-driven, and digital platforms can play a key role here. What’s more, as long as they take a farmer-led approach to how they develop, they’re likely to deliver the high level of detail we need to get the best out of the chemistry we’re using,” Alex concludes.

A Real Result despite a low disease year

The calcareous silty clay loam field chosen for the 2020 Real Results trial is one of the more uniform on the farm. “It can be hard to find a uniform field on the Wolds, but I’ve learnt you get much better results from trials if they’re located in consistent fields,” notes Alex.

Drilled in late October in difficult conditions following oilseed rape, the crop of KWS Siskin established well and the later drilling date resulted in lower septoria pressure in the spring. “It would have been interesting if there’d been more septoria, especially to see how the different rates of Revystar XE performed – you couldn’t really tell any difference between the treatments,” he notes.

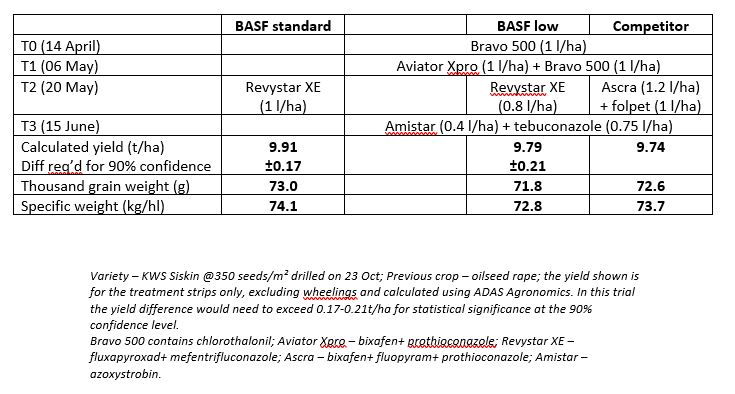

The level of disease was assessed on 24 June at GS75 by ADAS. Septoria was the only disease observed, at low levels up to leaf four. There were significant differences in percentage green leaf area (GLA) on leaf one and leaf three, with GLA lowest where the lower rate of Revystar had been used. The same trend was observed on other leaf layers.

“We got a better response in 2019,” Alex recalls. “It had been dry all through the spring, then the heavens opened in June after the T2 spray had gone on. The amount of septoria that developed on the flag and leaf two, especially in the non-Revystar treated areas, really made me rethink what the flag leaf spray is all about.”

The average measured yield of the Ascra treatment in the 2020 trial was 9.74t/ha, according to yield map data. This is likely to be a little higher than the true average due the exclusion of headlands from the analysis, notes the ADAS report.

“The field was harvested later than we ideally would have wanted,” continues Alex. “The crop was caught by some late storms and didn’t go through the combine until 11 Sept. By then, some of the grain had already shed.”

The modelled effect of the Revystar standard rate treatment was to increase yield by 0.17t/ha, relative to the competitor treatment, and the modelled effect of the Revystar low rate was to increase yield by 0.05t/ha, according to the ADAS report. But these would need to exceed 0.17-0.21t/ha to be deemed statistically significant at the 90% confidence level, so could have been due to other sources of variation, such as soil differences.

The protocols of the 2021 trial have yet to be finalised, other than that xarvio will have a role to play. “I’m sceptical about how useful xarvio will be, but will keep an open mind. However, with two years’ experience with Revystar, I can see where it delivers value in wheat fungicide programmes,” concludes Alex.

Hoehill Farm 2020 Real Results trials – Clickem

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their fifth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk or scan the QR code to visit the all-new, cereal fungicide virtual trial, offering a 360° map to compare plots.