With extreme weather events now the norm, successful autumn establishment has become even more of a challenge. CPM finds out how two farmers are managing risk.

With more roots, our crops are more efficient and can scavenge for nutrients.

By Charlotte Cunningham

With the end of harvest now in sight, and combines prepare to take a well-earned rest, focus turns to getting ready for next year’s crops.

The approach to crop establishment has shifted over recent years, with weather extremities meaning growers have to take a much more pragmatic approach to drilling – rather than just aiming for a specific date. This is in tandem with trying to time drilling to avoid weed pressures.

And then factoring in pressure from consumers and government to farm more with the environment in mind, the whole decision-making process around crop establishment becomes a bit of a minefield to navigate. So how do you strike the balance between optimising crop production and minimising the risks at this key timing?

In Fife, Matt Waldie is looking at all the options available to aid crop establishment under increasingly challenging growing conditions.

Weather remains his biggest agronomic challenge for Matt Waldie, who is often faced with either extreme drought or extreme rainfall.

Fourth-generation arable farmer Matt is the farm manager at 4 Front Farming Co, which operates across four farms with varying sites, from sea level up to 215m. “4 Front Farming Co is a collaborative between four farmers set up to use economies of scale to farm more efficiently, in a quest to farm more profitably and sustainably,” explains Matt.

Over the past five years, Matt has made the switch to a more regenerative approach, in a bid to marry up those ambitions of sustainability and profitability. “Up until 2016 our soil organic matter had been dropping – between 1993 it went from 7.84% to 6.1%. Yields had plateaued, yet our fixed and variable costs were increasing, and we had seen a reduction in the numbers of grey partridge on the farm too.

“Together with the increasing loss of actives and volatility on world markets, we knew we had to make changes to the way we were farming. So in 2017 we adopted a regenerative farming approach to restore our soil carbon. Our goal is to maintain and enhance the land that we farm and to increase our soils’ organic matter.”

To do this, the farm introduced cover cropping and moved to a system of direct drilling. The cover crop is an eight-way mix of different plants – including oil radish, phacelia, clovers, vetch and sunflower – drilled at the end of May and left to establish, he explains. “The multi-cover crop not only creates a huge green biomass above ground, but it also puts down an enormous root system that brings massive benefits to soil organic matter and increases the water holding capacity of our soils.”

Matt is using the cover crop mix not just for soil health benefits, but for the environmental advantages too, creating biodiversity havens ahead of the next crop for pollinating bees and insects. “We allow the cover crop to re-seed over the winter which also provides food and shelter for songbirds, and then spray off with Ally Max (metsulfuron-methyl+ tribenuron-methyl) in the spring.”

Matt uses an eight-way cover crop mix of different species which is drilled at the end of May and left to establish.

In addition to fertiliser savings from the use of cover crops in the rotation, he’s also saving money by direct drilling. “We’re using 6l/ha of fuel to establish our crops, as opposed to 50-80l with a conventional plough-based system. The reduced fuel use brings diesel and carbon savings.

“The use of direct drilling means we’re not moving any soil, so we’re drilling straight into a green biomass and allowing it to create a cover for the emerging crop. The blanket effect it produces also enables us to reduce our herbicide usage. Brome can be a problem, but we manage it with glyphosate.”

This cover crop “blanket” has also enabled Matt to stop using slug pellets and insecticides across the whole farm. “The brackling effect of the cover crop means we still get good air flow into the seedbed that keeps slugs at bay, and we have a huge population of ladybirds that help to control aphids, so we don’t have to worry about BYDV.”

They have also sought help from some four-legged friends, bringing mob-grazed cattle back on to the farm in a bid to help build more soil organic matter. “Our system is all about building organic matter to supercharge our soils and this is where the mob-grazed cattle come in. The worlds’ most fertile soils are the ones that have been created by large numbers of ruminants moving in mass. What we are trying to do is imitate this process.”

Matt has 300 cattle on the farm, which have been brought in through collaboration with one of the other landowners, Edward Baxter, who owns the herd. The cattle are grazed on the cover crop, moving them once or twice times a day depending on how much they’ve eaten and to avoid compaction. Land which isn’t suitable for food production is useable for mob-grazing grass leys. Grazing the cover crop and grass with cattle helps encourage top re-growth and a bulk of roots that all add to soil organic matter as it breaks down in the soil. It effectively creates a green manure, he adds. “Our focus is not just on sustainability, but on profitability too. You can’t farm green if you’re in the red.”

Winter oats drilled by Matt in September (photo taken in November). The left is naked seed and the right is the Newton-treated seed. Matt says the Newton treated had emerged 2.5 days faster than the naked seed and went on to establish much better into the winter, growing more vigorous roots and shoots.

Despite his efforts to bring in measures to overcome some of the hurdles associated with crop production, Matt says the weather remains his biggest agronomic challenge and he’s often faced with either extreme drought or extreme rainfall. “At 215m above sea level we need to get crops in early and in good condition in the winter.”

“In the spring, we need to get the barley deep rooting as fast as possible. Where we’ve adopted the direct drilling system, we’re able to drill our winter crops earlier and into better conditions, and with that comes an earlier harvest the following year.”

At this stage, Matt has also seen benefits from the use of a biological tool called Newton – a biostimulant seed treatment from Interagro. “We use Newton biostimulant seed treatment on all our crops except the beans – on the oats, the wheat and the spring barley. Especially in the winter, we’ve seen big improvements in emergence with a good two-three days earlier emergence from using Newton compared with undressed seed. They develop more tillers which gives us higher yield potential and provides better frost heave resistance through the unbelievable rooting it provides.

“We have to focus on a way to make our business more resilient and sustainable. With more roots, our crops are more efficient and can scavenge for nutrients. It costs so much to establish a crop, the more you can do early the better. We’ve achieved higher yields with Newton and now use it across the farm.”

Newton has also proved beneficial in the Midlands for Simon Bayliss, farm manager at Wincote Farms in Eccleshall, Staffordshire.

Simon Bayliss is eight years into his regenerative farming journey across 273ha and has seen soil and plant health go from strength to strength with yields averaging 11.5t/ha in a “normal” year.

His ambition is to achieve resilience and self-sufficiency has driven much of the decision-making on farm. “Tight, compacted soils were the motivation to start taking soil organic matter more seriously,” he explains. “It makes good logic that if you have healthy soils you will grow healthy crops.”

Simon started out in the mid-2000s using green waste compost supplied by the local council and while that made a big difference to the condition of heavier soils, microplastics were found in the compost so he stopped using it.

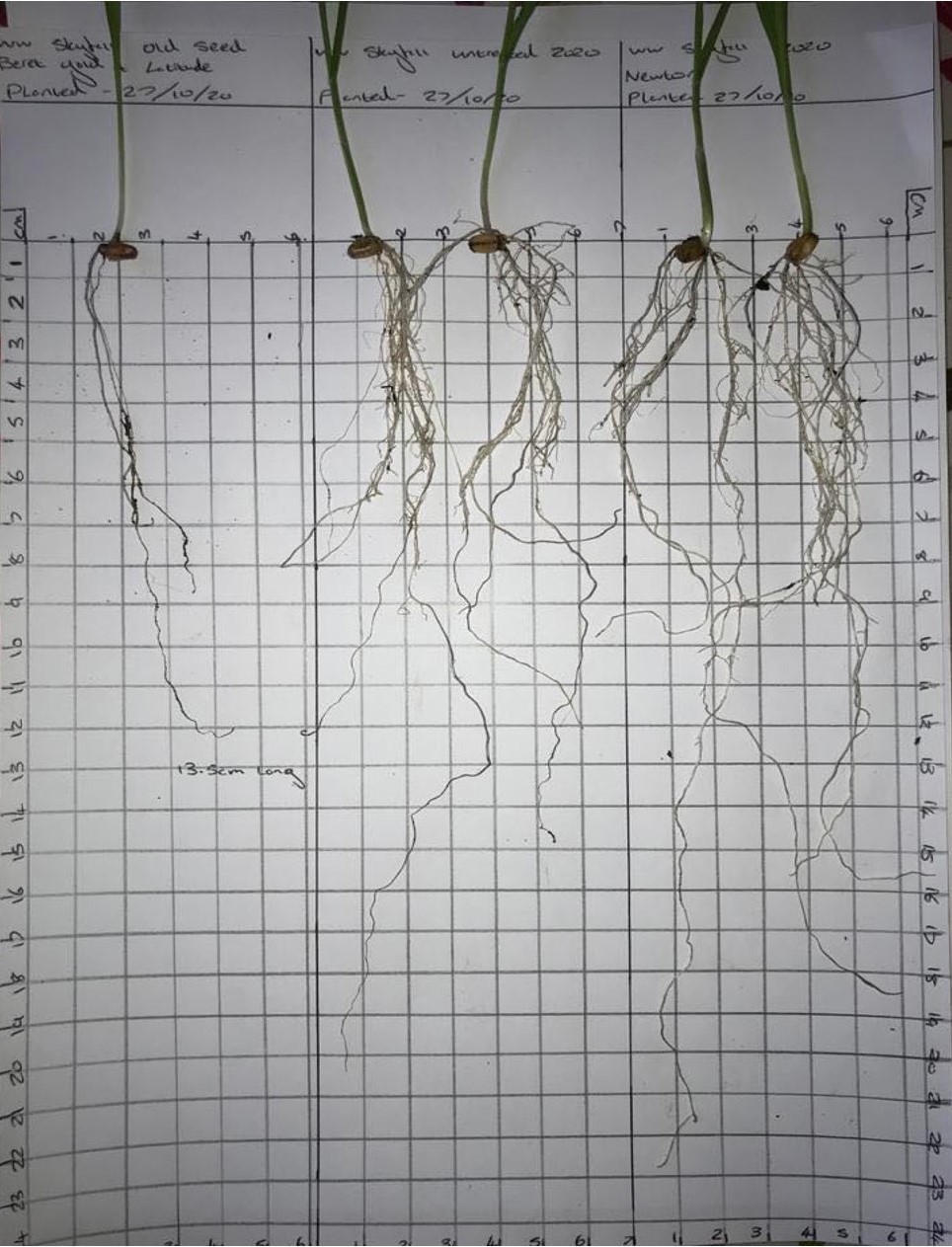

To test the benefits of Newton, Simon set up a three-way tramline trial comparing Beret Gold plus Latitude (left), untreated naked seed (centre) and Newton-treated seed (right).

Quickly changing tack, Simon began focusing on reducing cultivations instead, with the help of a Claydon Hybrid drill. “It improved our soil structure and organic matter even without the compost. Then, four years ago, we made the decision to move away from the contract farming business we were operating across the country to move things on so we could concentrate on our own farming resilience. We’re now fully regenerative, pretty much.”

The benefit of this transition is evident within the soil organic matter content which has gone from an average of 1.6-1.7% across the farm to 7.2% on some parts, and 4.5% on others. “Yields have also increased from 10t/ha in our old conventional system to 13.8t/ha in the best of our regen fields.”

To feed this organic matter, all soil is chopped and left, adds Simon. “Straw has huge value in terms of organic matter and P and K. We chop the straw at harvest and leave this on the surface to decompose over time which supports soil biology and helps build soil structure for healthier crops.

“Straw obviously has a monetary value, but we value its nutrient benefits more. It also removes the risk of compaction from balers coming into the field. It’s helped us reduce our fertiliser use as we’re now down to 150kgN/ha in the wheat and just 80kgN/ha in the barley, which we apply in the form of liquid fertiliser.”

For the past five to seven years, Simon has also been applying digestate for its fertiliser value. “I will only have 100% food waste. We did struggle to get the volume we needed this year and have had to apply some liquid N to top it up, but we use an N-tester and SAP test twice in the growing season to ensure we’re only feeding the crop what it needs. We’ll also apply a foliar biostimulant twice in the growing season to help optimise nutrient uptake and feed plant health.”

Variety choice also plays a fundamental role in the strategy, with early maturing, robust types selected for early drilling and to reduce chemical inputs. “All our wheat is Skyfall, which we grow for feed rather than milling, and all the barley is Bazooka. Both are early maturing and suit our September drilling preference.”

As part of Simon’s regenerative approach, no insecticides, growth regulators or post-emergence herbicides are used, and fungicide use has also been dramatically reduced. “We prefer to feed enzymes and biology during the season.

Simon Bayliss is eight years into his regenerative farming journey across 273ha in Eccleshall, Staffordshire.

“We apply liquid silicon for disease control and will only apply a T2 fungicide for rust if we have to, though we don’t have any problems with septoria. We’ll stick with Skyfall for another season but may move to another early driller, like Graham, for better rust resistance,” he adds.

So where does Newton fit into the programme? All seed is home-saved and chemical dressings have been replaced with a more natural alternative in the form of Newton. “We moved away from chemical seed treatments three years ago and now have Anglia Grain Services treat all our wheat and barley seed with Newton biostimulant seed treatment, explains Simon.

“I wanted to move away from chemical dressings to protect soil biology and when I read about Newton, I was keen to test it for myself. So, I set up a three-way tramline trial comparing Beret Gold (fludioxonil) plus Latitude (silthiofam), untreated (naked) seed and Newton-treated seed.

Matt has 300 cattle on the farm, which are grazed on the cover crop in a bid to build soil organic matter.

With straight Newton, Simon says there was a huge improvement in the structure and size of roots. “Newton is all about root development and better crops – the root system and root length were greatly improved over Beret Gold plus Latitude and the untreated. Newton also puts our crops streets ahead on emergence, by a good two days compared with untreated seed and four-five days faster than the chemical dressed seed,” he adds.

“Crops do better when they are up and out of the ground quickly, especially in warm weather to put their roots down. Now we have all our wheat and barley seed treated with Newton. Our crops are up faster, we get more nutrient uptake and a better symbiotic relationship between the soil biology and the plant which gives us better crops.

“Healthier crops are giving us higher yields and from using less chemicals across the farm in general, we are seeing more insects, bees, butterflies and wildlife.”

Knowledge on Newton

Newton is a peptide-based biostimulant seed treatment, suitable for use on conventional and organic crops, designed to optimise seed health at drilling to promote and protect final yield potential, explains Stuart Sutherland, technical manager at Interagro.

“These signalling peptides play a fundamental role in the regulation of growth and development and crucially, lad to faster germination and emergence. Climate change is putting considerable pressures on farmers and their crops, and the window to establish a fit healthy crop before the winter sets in can be tight.

“Therefore, by using Newton at the time of drilling, growers can speed up the growth of young seedlings and stimulate deep-rooted, well tillered plants which are much better prepared to cope with the cold, wet stressful winters that may follow. What’s more, the unique stress-busting peptides help the plant cope better under stress and support higher emergence,” he claims.

Newton is recommended at a rate of 1 l/t of seed at a cost of approximately £3-4/t. It’s compatible with other seed dressings and can be applied through a conventional seed treater or a mobile treatment system.

Pushing performance

At the heart of good crop production lies careful use of chemistry to protect the plant and maintain performance, right through the season. But optimising the efficacy of plant protection products can be challenging, while increasingly restrictive regulations limit just how far you can go.

This series of articles explores the science behind the use of adjuvant and biostimulant tools to help power both chemistry and crop performance, as well as increase understanding of why they’re needed and what they do. We’re setting out to empower growers and drive crops to reach their full potential.

Newton is an organic biostimulant seed treatment that promises vigorous crop establishment minus the stress. Newton has been shown to speed up emergence by several days and fuels exceptional increases in rooting for better nutrient uptake and resilience against drought and other environmental stresses. Less stress for you, less stress for your crops.

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.