Waiting for the right soil conditions and keeping the crop standing are two key aspects of success for a N Yorks grower with plenty of experience in large blue combining peas. CPM pays him a visit.

The only way you’ll get farmers to grow peas is if they stand up.

By Tom Allen-Stevens

Mark Sampson is fairly frank about what he feels the secret is to growing a successful crop of large blue peas: “With peas, you just have to get the soil structure right. Everything else is pretty easy.”

But this could belie a modesty that comes from around 25 years’ experience with the crop, and you get the impression that things don’t just fall into place at Acclom House, one of two units he farms at Bedale in N Yorks. There’s a meticulous care that’s evident as he looks through records of inputs applied to the crop. Then in the grain store, there’s barely a flake of dust among the well ordered and tidy silos.

Most crops grown on the 340ha of magnesian limestone to blowing-sand soils are destined for seed. “It’s a pretty standard seven-year rotation we follow. There are three breaks – potatoes, peas and oilseed rape – with winter wheat the main cereal. We also grow naked oats before the OSR as it comes off a bit earlier,” explains Mark.

The potatoes are sold to the local fish and chip shop market, while the 16ha pea crop is grown on contract for nearby I’Ansons for the micronizing market (see below). “On areas not suitable for potatoes, we have grown linseed, but we’re not growing that any more – its harvest is too late and it’s getting more popular.”

Peas, on the other hand, have been in the rotation for almost as long as Mark’s been farming, and he’s clear on what makes a good variety. “The only way you’ll get farmers to grow peas is if they stand up – no one wants to spend £250,000 on a new combine harvester just to fill it with soil.”

That’s why Campus has been grown every year since it first appeared. “The very first Campus was grown here – we were supplied breeders seed from which we grew a pre-basic crop in 2013, and we noticed how well it stood.” With a score of 8 for standing ability, it still has the best score on the PGRO Recommended List, he points out, although its low yield score makes it outclassed.

“I’d rather harvest 100% of a crop that yields 93% of controls than a variety that may have a 107% yield, but you end up leaving 20% in the field,” he points out.

The farm’s Higher Level Stewardship agreement means stubbles stay in place until 15 Feb. The aim is then to spray off with glyphosate the next day and plough with the Kuhn Variwidth a week later.

“Soil structure is important for peas, but it’s not rocket science,” he says. “The main aspect is to keep off the land if it’s too wet and don’t overwork it. We generally go straight into the plough with the combination drill. If needed we’ll make a pass with the Shakaerator, but anywhere with two passes tends to lose moisture. We don’t grow cover crops, but find oats and linseed are fantastic for helping soil structure.”

Mark finds overwintered ploughed soil sits too wet to work into a decent seedbed in the spring, while spring ploughing rarely brings problems with compaction, that can be a severe limitation for peas. He aims to drill between mid March and mid April, guided by soil conditions. “Seed rate was 190kg/ha last year – 200kg/ha is generally the magic number.

“The depth needs to be set so the seed gets to the moisture – generally around 50mm for us. It turned very dry last year and we almost had to irrigate, which we can do.”

He reckons peas do benefit from potash, so applies 200kg/ha of MOP. There’s a strong spend on herbicides, with the pre-emergence Nirvana (imazamox+ pendimethalin) and Lingo (clomazone+ linuron) followed up with in-crop Tropotox (MCPB) to address broadleaf weeds. Manganese is routinely applied to all crops, and peas in particular.

Powdery mildew also gets attention, with Alto Elite (chlorothalonil+ cyproconazole) sprayed in mid June, followed up with Signum (boscalid+ pyraclostrobin) three weeks later. “We noticed some crops in the area were plastered with the disease last year, but ours was spotless,” notes Mark. He rarely has to spray for insect pests, however, with last year’s crop receiving just one mid-June dose of Aphox (pirimicarb) for aphids.

As harvest approaches, he tries to avoid a desiccant. “Good control of weeds should mean nothing’s needed, but we’ll go with glyphosate if necessary. You need nerves of steel for Reglone (diquat) as it makes the stems very brittle. I’m also convinced a pass with the sprayer at that time of year does a lot of damage to the crop.”

The trick with keeping the quality with peas is not to leave them standing in the field, he stresses. “The buyer looks for a nice, green colour in the sample and sunlight causes bleaching. So if you’re lucky, you’ll combine the crop on the first day it’s ready.

“We fetch it in as soon as it reaches 20%, then dry it. We have a Simplex bin-drying system, installed in 1959, that works well and peas are a relatively easy crop to condition.” Conversely, a pea that’s too dry, down to 14-15%, can crack and split easily in the combine, he notes.

Last year his crop yielded 5t/ha, although it achieved 6t/ha in 2015. “Headlands tend to be a bit disappointing, but as long as it’s standing, a pea crop will yield and combine well. That’s worth bearing in mind as it looks as though some of the newer varieties on the RL may have lost the ability to stand,” notes Mark.

Trade tends to turn to trusted growers

The micronizing market is the main premium outlet for large blue peas, which take up an estimated 75% of the UK combining pea market, covering about 30,000ha.

A small portion of large blues head to the high-value snack food market, fetching prices as high as £240/t ex farm, although very little of the 2017 crop made the grade, according to the British Edible Pulse Association (BEPA). Those destined for the third-tier canning market, currently oversupplied, will command little above £165/t.

The market for combining peas “continues to lack excitement,” says BEPA president Franek Smith. But forecasts suggest that by 2019, crop contract prices will have risen significantly higher as both carryover stocks and production levels fall through 2018.

I’Ansons, based in Masham, N Yorks, is one of the leading manufacturers of animal feedstuffs, according to group grain buyer Howard Jackson. The firm processes about 1000t/mth of large blue peas for the firm’s micronized feeds.

This is a process that uses infrared rays to cook cereals and pulses at lower temperatures and for shorter times than other methods. Passed under burners on variable-speed belts, a roller mill then creates flakes that can be used whole or ground into a meal. This is claimed to bring improved nutritional value, boosting available energy and digestibility as a result of the gelatinisation of starch molecules during the cooking process – particularly useful for young animals and poultry.

“We buy as much raw material as we can from around 400-500 trusted growers in and around Yorks and the north of England, but we’re always on the look-out for new growers,” explains Howard.

Campus is a variety that suits Yorks growers well, he says, while for those further north he recommends Zero4 as it’s earlier to harvest. “Daytona also fits the bill, but it’s not as deep a green as we would like.”

The company carries out trials and never offers a contract for a variety until they’ve tested it and are confident it’ll perform commercially. “Colour is of key importance. We’ll buy on sample, and generally the colour depends on the season – a wet harvest will cause problems. It’s important there’s low admix in the sample, while split and cracked peas can cause rejections or deductions, although this is rare.”

Howard believes attention paid at planting reaps rewards. “The land has got to be right – peas like to go into a warm soil, so don’t get carried away and plant too early. Also make sure there’s as little compaction as possible.

“Don’t put on too heavy a seed rate,” he continues. “The flowers need plenty of room to pollinate.”

It’s Mark Sampson’s attention to detail that makes him a trusted grower for I’Ansons, notes Howard. “He doesn’t cut corners and he doesn’t rush. He regularly hosts our trials and other variety trials, and you know that whatever variety you give him to grow will look its best when it comes to open days or grower demonstrations,” he says.

- The BEPA Open Day takes place on Mark Sampson’s farm on 21 June, 2018 – all growers are welcome to attend this free event.

Will the pulse quicken for peas and beans?

Those with peas and beans to sell should take note of recent movements on the market, comments PGRO’s Roger Vickers.

“The Australian bean crop has been around 300,000t – approximately half that of 2016 and returning to near normal levels. This may have some impact on prices going forwards,” he reports.

“Meanwhile the effect of the Indian import tax (of 30-50% depending upon pulse type) is putting price pressure into the world market and a more negative attitude with Australian growers. France too is impacted by these import tariffs, as it exported over 100,000 tonnes of peas to India last year.”

The UK feed market for beans is picking up as soya and rape meal values rise and significant feed compounders are looking to cover their summer requirements from beans as a good quality alternative, he adds. But the human consumption bean export market has stalled and shows little sign of renewed interest.

“The trade is still uncertain of the likely pulse area to be sown. Spring bean seed is in demand, but with the perception that less seed crops were realised in 2018, seed availability may be no clear indication of likely sowings,” notes Roger.

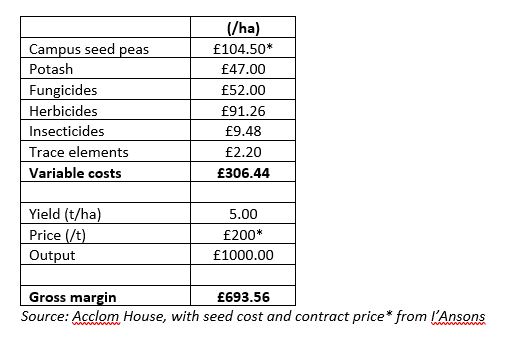

Large blue peas: how the finances stack up

Farm facts

Acclom House, Bedale, nr Northallerton, N Yorks

- Farmed area: 340ha

- Cropping: Winter wheat (KWS Siskin, LG Sundance); winter oilseed rape (Alizze, Aquila); potatoes (Estima, Sagitta, Maris Piper); large blue peas (Campus); permanent pasture for 90 head of beef cattle

- Soils: High magnesium limestone to blowing sand, with some black earth silt

- Mainline tractors: New Holland T7.235, T7.210, T6080

- Combines: Claas Lexion 620 with 5.6m header

- Loader: JCB Loadall 526-56

- Drill: 3m Kuhn power-harrow combination

- Plough: 5f Kuhn Variwidth

- Cultivation: 3m McConnel Shakaerator; 6.2m Cousins rolls

- Drier: 8x Simplex 40t silos

- Staff: two full-time plus Mark and son Harry.