Judicious use of new techniques, following on-farm trials, is helping the estate manager of a family-owned Notts estate bring long-term benefits to its arable enterprises. CPM calls in as the latest harvest results are assessed.

By Tom Allen-Stevens

There’s a new drill that takes pride of place in the yard of Grange Farm on the Oxton Estate, near Southwell, Notts. By the start of September, it had only established 36ha of oilseed rape, but estate manager Richard Cross has high hopes for how it’ll take forward his aspirations for this traditional, family-owned estate.

“It should save us around £70/ha, and rather than moving soil and bringing up lumps that we then have to bash down again, it’s part of our aim for a more friable soil structure that needs less working to establish a crop,” he says.

The composting site has recently received a multi-million pound investment to upgrade facilities, and currently takes in 75,000t/yr of green waste.

There’s a steady change he’s overseen since he arrived on the 1000ha estate in 2010, which marries the best application of new technology with the farm’s inherent experience and knowledge of the lie of the land. “Our costs may be higher than some of the leaner arable farms, but this estate has been in the same family for 500 years, and at one stage had three members of staff with 134 combined years of service between them. So we’re modernising and introducing efficiencies in a way that we can be sure will bring long-term benefits.”

And there’s plenty to suggest this is a thriving, diversified rural business – aside from the 770ha of arable crops, there’s 160ha of grassland and 70ha of woodland, forming part of Sherwood Forrest, that supports a large shoot. There’s a golf course, composting business and even a green burial ground. With 28 residential properties, the estate is also branching out into commercial lets.

“The arable land lies on two distinct soil types,” explains Richard. “We’ve Notts sand and gravel that benefits from borehole irrigation, so has a rotation of vegetable crops on land let out one year in three or four. The rest of the rotation on these lighter soils comprises winter wheat and maize, the latter grown for Severn Trent’s anaerobic digester.

“The rest of the farm is a very different Keuper Marl heavy clay. Here we’re growing winter wheat and oilseed rape, with spring barley in the rotation mainly to keep on top of blackgrass – we’re trying to grow as few second wheats as we can.”

It’s these soils, combining the twin challenges of heavy land with steep slopes, that have seen the biggest evolution in cultivation practice. “When I first arrived, there were four Kuhn power harrows that formed the backbone of autumn cultivations. Everything was ploughed and pressed and then bashed into a seedbed,” Richard recalls.

“We started to rationalise, introducing a Sumo Trio and Väderstad Rexius Twin, and losing two of the power harrows. Since then, the staff on the arable side has dropped from seven to three, and we’ve been going progressively shallower.”

More recently, a 5m Proforge Inverta speed-disc harrow has lifted cultivations further to as little as just 5cm depth. But the Kverneland tine-seeder drill, extended from 4m to 4.8m width, was proving to be a limitation. “We’ve been moving all the soil just to make a seedbed for the drill, so we looked around for alternatives.”

Costing £3.50/t to deliver and spread, the compost improves the drought resilience of the sand and gravel soils and workability of the clays.

Settling on a 3m Mzuri Pro-Til drill, this is designed to strip-till in front of seed sown straight into 33.3cm rows in one pass. Covering 30ha/day, Richard estimates the time, diesel and wearing-part savings will quickly cover the investment. But he’s not rushing into a one-pass system, with at least a light cultivation likely to remain part of procedure with the cereal crop for the time being.

“It’s not a silver bullet – there’ll still be areas of compaction we’ll need to take out, and there’ll be years when wet conditions may mean it’s simply not the most suitable tool for the job. But the move to strip-till drilling complements other moves we’ve made to improve the drought resilience of the sand and gravel soils and workability of the clays.”

This is where the composting operation comes in. This started as a joint venture with green waste operator Simpro in 2006. Now the 4ha site is operated by Veolia UK, which has recently made a multi-million pound investment to upgrade facilities, and currently takes in 75,000t/yr of green waste.

“We spread 10,000t/yr of compost on the farm, rotating it so every field gets an application once every 3-4 years. On the lighter land, this adds humus and body, and aids moisture retention, while the organic matter opens up the clays and makes them more friable,” Richard explains.

“It contains around 5% of a slow-release N, 7% P and 9% K, but this is a soil conditioner, not a fertiliser – the nutrients aren’t readily available.”

The compost is supplied free of charge, with the farm paying for haulage and spreading. “This costs about £3.50/t spread. Waste regulations limit applications to 33t/ha per year or 66t/ha biennially, but we find the biggest limiting factor is moving the compost on to the land at suitable times of the year.

“Currently, we incorporate it with the plough, although I’m looking into shallower cultivations.”

All of the straw is baled, much in demand by local carrot growers, although Richard reveals this may come under review to ensure further improvements in the estate’s soils. “It’s difficult to pinpoint or quantify the benefits, but workability’s improved, and the fields that were really knotty are showing a considerable difference.”

Along with improving returns, the long-term objective is to remove variability from the contrasting soils, and Richard’s considering trialling precision seeding technology to complement other changes he’s made.

“What we’re aiming for is consistency, from every ha we farm. We’ve brought this estate from using very little technology to benefiting from some of the best available, judiciously applied alongside traditional practices. We still want a barnful of wheat every year, and through careful application of new techniques, following on-farm trials, I’m confident that’s what we’ll achieve.”

Harvest results confirm a GAI boost

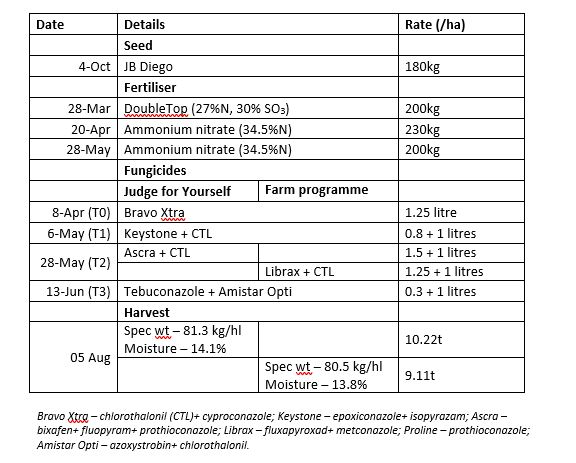

Richard Cross has been involved with Bayer’s Judge for Yourself (JFY) trials since they first started to pitch Aviator Xpro against other fungicide programmes used on farm. “I’m BASIS and FACTS trained so already quite involved in decisions on the fungicide technology we use. The on-farm trials add a bit more interest to the job,” he says.

Lately, he’s been particularly keen to see whether Ascra can complement the farm’s soil-improvement programme. “We’re trying to eke out that little extra bit from the crop. With the soil, we’re looking to improve rooting and moisture retention. Above ground, it’s all about getting sunlight into the canopy and building yield. If we can change practice so the crop retains its green leaf area for longer, that should extend the grain-filling period.”

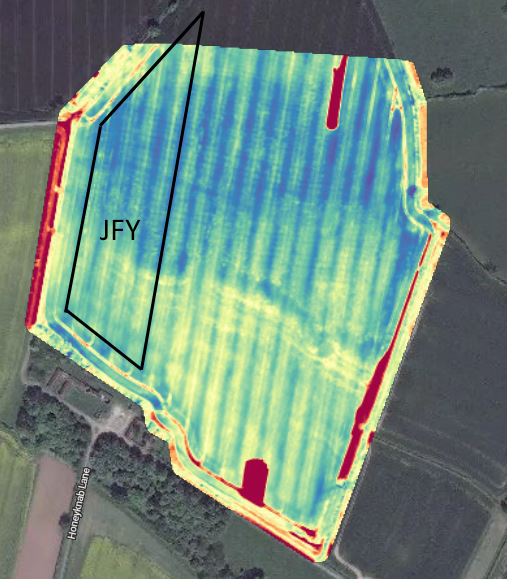

So along with harvesting separately the 2ha plot treated at T2 with Ascra, the field was flown over on 28 June with a drone fitted with a Normalised Difference Red Edge Index (NDRE) camera. This highlights the differences at the far-red end of the light spectrum much more clearly, giving a good indication of any differences in green area index (GAI).

The NDRE image this year hasn’t picked out the difference quite as much as it did last season, probably as a result of the drought.

“Ascra has a label claim for the physiological benefits it brings the crop,” notes Bayer E Mids technical manager Darren Adkins. “Research indicates that every day you can extend green leaf area adds an extra 0.15t/ha of yield to a wheat crop. We’re monitoring the JFY trials carefully to assess what difference it makes.”

The results on Richard’s farm are looking promising. “In 2017, Ascra was pitched against Elatus Era (benzovindiflupyr+ prothioconazole) at T2 on Skyfall, and then against Librax this year. The NDRE image this year hasn’t picked out the difference quite as much as it did last season – probably as a result of the drought. But in both years the crop treated with Ascra has performed 1t/ha better.”

Ascra was first used on the farm in 2016, before its commercial release, recalls Richard. “It was very noticeable how much greener the area was. Driving through with the sprayer, the crop in the treated area just looked that bit healthier,” he notes.

“Ascra’s a step on from Aviator that also has an ability to keep the crop growing. Previously, Seguris (epoxiconazole+ isopyrazam) seemed to have the edge with yellow rust, although it didn’t give the ultimate performance you’d get from Aviator. But I’ve noticed with Ascra, you don’t need to top up with anything else for yellow rust.”

Two very different years with positive results are enough to convince him it’s a treatment to consider over the rest of the wheat area, in his quest to bring a little bit more productivity into the wheat enterprise. “Ascra was used in the trial at 1.5 l/ha, which is a little higher than a rate I’d probably use at T2. But if we can replicate this yield benefit across other parts of the farm, that’s certainly a change worth making.”

And the rewards from eking out that little extra may be quite substantial – the estate has recently started to grow KWS Montana, a high quality German E wheat, well suited to the sands and gravels. Grown on contract for ADM, it attracts a £40/t premium over feed wheat if the protein exceeds 14.6%.

“This year was our first harvest, with 100ha, and while it yielded just 5t/ha, the protein was hitting 16%. It’s a crop you have to keep spoon-feeding with N, and it needs plenty of PGR as it does grow tall. But if we can get its end of season right, we could really earn some big bucks from it,” notes Richard.

The green screen: wheat SDHI programme on trial

Award for place of quiet contemplation

It’s not just the compost that’s interred at Oxton – there’s a 5ha natural burial ground on the edge of Sherwood Forrest, established with wildflowers and where wildlife is encouraged. Single plots are purchased for up to £550 apiece, with relatives given free access to the tranquil meadow. With the option to plant a tree to mark your final resting place, residents must be buried within entirely biodegradable materials. The meadow has just won the title of Best Burial Ground in the UK at the 2018 Good Funeral Awards.

Partners in Performance

Partners in Performance is the result of a long-standing collaboration between Bayer and a group of progressive growers.

It started in 2011with the launch of Aviator Xpro when growers were invited to trial Aviator on their farm. In these split-field trials Bayer took a back seat with the only demands being the field area for fungicide comparison and crop yield verified over a weighbridge or via combine yield monitor – everything else was down to the farmer.

Over time this developed into more of a club. Each year the farmers would meet to discuss results, listen to guest speakers and debate winter wheat management issues.

Farming has always been a challenging business, and with Brexit those challenges have intensified. The margin between profit and breaking even is likely to become even tighter and any incremental gain will be needed for sustainable combinable crop production.

To achieve that the industry needs to work together to share the latest research and thinking, exchange ideas and experiences.

Partners in Performance aims to bring farmers and specialists together to develop solutions to improve crop performance and investment return.