A variety strip trial is one of a number of measures used by the Stody Estate in Norfolk to evaluate how to improve performance of its oilseed rape crop. CPM visits to gather early results and pick up some tips.

These are genetics we’re familiar with, and we have confidence in the traits they express.

By Tom Allen-Stevens

A reservoir holding 225,000m³ of water on light soils in North Norfolk is a fine sight to behold, especially as this year’s drought begins to bite.

“The wet winter has been useful,” notes Mike Wilton, farm manager of the Stody Estate, near Holt, just a few miles from the North Norfolk coast. Completed in August last year, the new reservoir complements an existing one of 45,000m³ capacity and supplies a 23km underground network of pipes to bring irrigation to the estate’s potatoes, sugar beet, carrots, parsnips and onions.

DK Exalte and Expansion as well as HOLL varieties V316OL and V353OL are the varieties currently grown commercially.

Owned by the MacNicol family, the estate takes a long-term view of farming over its 1250ha of in-hand arable crops, explains Mike. While land is let out for most of the vegetable crops, he manages the combinable and root crops in-house, along with another 500ha contract farmed. There’s a 12-year rotation on the sandy loam soil with high stone content, putting winter wheat, oilseed rape, winter and spring barley in amongst the root crops. Maize is also grown for an anaerobic digester on the nearby Holkham Estate.

Mike takes the same long-term view with OSR, a crop he believes is worth investing in, both in terms of resource and knowledge. “If all you do is take seed off the heap and try to spend as little on OSR as possible, you start it off in a bad place, and it’ll be a crop that’s destined to fail,” he says. “We don’t have quite the same pressure here from cabbage stem flea beetle that hotspots have, so provided it’s given the right management, it’s still a very valuable crop.”

He’s distilled this into a five-point plan he aims to deliver:

-

- Invest in good genetics

- Maintain a sustainable rotation

- Keep the soil in good condition

- Give the crop nutrition at drilling

- Ensure moisture at establishment

Mike conducts a set strip trials of different varieties to ensure he’s getting the first point right. For the past ten years, he’s been part of Bayer’s Judge For Yourself network of growers carrying out on-farm trials, and recently this has broadened out to include OSR genetics. Bayer assists with site layout, candidate selection and monitoring of performance throughout the year, and joining him to review the season (maintaining social distancing guidelines) is local Bayer commercial technical manager James Wilkins.

“I’ve been working with field trials for many years, and know their value in comparing different treatments,” he says. “The advantage of carrying out your own on-farm trials is that you can see for yourself how various products perform within your own unique management system.”

There’s 220ha of OSR across the estate, with DK Exalte and Expansion as well as HOLL varieties V316OL and V353OL, explains Mike. “We have a fair area of virgin OSR land, so it made sense to start growing HOLL varieties, especially when the varieties became as high-yielding as other hybrids. The HOLL market has shrunk, though, so I’m not sure we’ll stick with them.

“DK Exalte and Expansion have served us well and look good this year, so I think we’ll continue with these. There are now some interesting new lines from the same stable that we’ll look to mix them with, depending on the trials results. What I’m looking for are good autumn and spring vigour, the Rlm7 gene for phoma resistance and pod-shatter resistance – it’s no coincidence that those are also the characteristics you find in the Dekalb varieties.”

James notes that the Dekalb breeding plots are kept untreated and under high phoma pressure, ensuring only those with good resistance scores come through.

With up to 14 crops in his rotation, that does offer Mike the opportunity to keep OSR well spaced out. “A long rotation is the secret to success with OSR,” he states. “We’re currently growing it once every six years, although there have been parts of the farm in the past where it’s been it been grown every other year and fields where it’s never been grown.”

Other critical aspects are seed rate and size. “I’m very particular about the seed I plant. The thousand grain weight can vary more than you might imagine and I’ve received seed that ranges from 3.4-8.1g/1000 seeds. There’s no point in having extra vigour in a small seed as it won’t have the stamina to germinate and survive in challenging conditions. I now won’t take any seed lower than 5g/1000 seeds,” he says.

“There are those who raise the seed rate for CSFB, but I still believe a low plant population works best, and it’s crucial if you want to get the right canopy. We drill at 40 seeds/m² in 315cm rows, aiming for a final population of 25 plants/m²,” continues Mike.

James agrees that barn-dipped, high seed-rate OSR is a recipe for failure. “All the evidence shows that you don’t reduce the larval damage from CSFB by presenting more plants to the pest – small, weak stems will not tolerate attack, while stronger thicker stems stand a much better chance.”

Although Mike has a Väderstad Biodrill and could establish the OSR in one pass, he’s not a fan. “Evenness of drilling is important – you want the whole crop to emerge on the same day to give a higher population than the CSFB can manage. Our 8m Väderstad Spirit drill ensures very even results, so it’s not worth compromising.

“Another crucial aspect is to give the plant every opportunity to root. Our light soils don’t self-structure very well, so we find a pass with the 5.5m HE-VA Combi-disc down to 200-300mm is needed.”

All straw is removed in front of OSR and cultivations follow straight after the combine to give time for volunteers to chit before drilling. “OSR needs readily available nitrogen and phosphate at drilling. So around five days before we drill, we apply 125kg/ha of diammonium phosphate (DAP). Sometimes the land will receive digestate from the AD plant,” says Mike.

But he’ll wait until the time is right before he puts the drill in. “Moisture in the seedbed is a fundamental part of success, so drilling can’t be decided by calendar date. We wait until there’s the prospect of rain and then we go. We’ll roll behind to lock in the moisture, although seed-to-soil contact isn’t such a problem on our light land.”

Generally the crop receives an autumn fungicide of Proline (prothioconazole), followed up with another triazole if disease pressure is high. Another dose of Proline will be applied at early stem extension in the spring.

James notes that analysis of leaf samples sent to ADAS for SpotCheck in March showed relatively high levels of light leaf spot, with 127 of 137 samples testing positive. Almost three-quarters of the samples had levels above 25%, he adds.

“Better LLS resistance is something we’re looking for in varieties going forward,” notes Mike. “We use the AHDB sclerotinia prediction model to help manage the disease. This year we’ve been trialling Aviator at mid flowering on the Dekalb strip trial as well on an entire field.”

James reports that the treatment delivered an average 0.2t/ha yield advantage over the farm standard in UK trials last year. “In addition to light leaf spot and sclerotinia control, it should bring to OSR the benefit of the Leafshield formulation system seen in cereals to bring a little extra yield at the end of the season,” he notes.

Mike will wait to see how the crops pass through the combine before making a judgement on what changes he’ll bring to his OSR management as a result of the trials he’s doing. But he remains confident in the system he has. “With OSR, you have to get the fundamentals right, but the best way to make improvements is to learn what works through on-farm trials,” he concludes.

New technology goes on trial

It’s been ten years since the first Bayer Judge For Yourself trial on the Stody Estate, which puts Mike in a reflective mood, especially in light of the current lockdown restrictions.

“It’s been a really good experience – Bayer’s kept the right mix of keeping us informed while putting on interesting events that bring the group together. It’s not all about how to get the best out of Aviator (bixafen+ prothioconazole). You meet farmers facing the same challenges as yourself, and while I know a lot about Norfolk, it’s a good opportunity to get a UK-wide view on farming. With the current COVID-19 restrictions, the networking and opportunity to exchange views are aspects I really miss,” he says.

On the farm itself, trials have always formed part of the operation for him. “On every farm I’ve managed we’ve done in-house trials. One of the differences with the Bayer trials is that you get a look-see at new technology before it’s rolled out on full commercial release, which I find really valuable.”

This year, he’s taking a look-see at Climate FieldView, Bayer’s new digital farming platform. Already used across 36M paid ha, mainly across North and South America, it’s currently on trial in the UK, notes James. “We still have availability on our trial for growers to look at FieldView for a year free of charge.”

Mike has received a FieldView Drive unit, a gadget the size and shape of a doorknob that sits in the tractor or combine controller area network (CAN) port. This feeds data through to the Cloud in real time via an app that sits on an iPad in the tractor that’s connected to the Drive via Bluetooth.

Mike’s hoping FieldView will bring more information on his crop and easier access to yield information. “Things are going to change – we’ll need to justify more our decisions to treat a crop. That can only be a good thing as we’ll make decisions more in line with what’s actually happening to a crop, rather than guesswork. While I can already get the yield I need through machinery manufacturer platforms, access can be difficult. I’m hoping FieldView will be easier to use.”

James has brought with him a Scouting map from Mike’s OSR trial field, taken from a satellite image with the app. “The image clearly highlights the best and worst areas of the field in terms of field health and is calculated from the vegetation satellite map. It’s a useful tool in identifying any issues early so that action may be taken to protect yield as well as managing expectations before harvest. Mike can easily share this field information with his agronomist to help make better informed decisions,” he says.

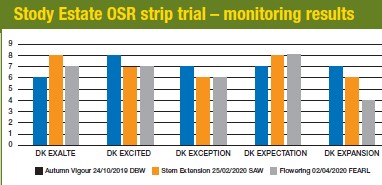

The map doesn’t show up the differences between the varieties, however, so James has brought the initial monitoring results. “The mild autumn has meant that the autumn scores are relatively close together, while this is data from just a single trial,” he cautions.

“DK Excited is one that really stands out, and it has the advantage that it carries resistance to TuYV. DK Exception has a good autumn vigour score. Also included in the trials (but not shown in the chart) are a couple of new coded lines that demonstrate very promising autumn leaf development and flowering,” he adds.

“DK Excited is one that really stands out, and it has the advantage that it carries resistance to TuYV. DK Exception has a good autumn vigour score. Also included in the trials (but not shown in the chart) are a couple of new coded lines that demonstrate very promising autumn leaf development and flowering,” he adds.

Mike’s noticed considerable differences between the varieties in the strip trials. “There are one or two of these varieties that promise a good progression from the Dekalb lines we have at the moment. These are genetics we’re familiar with, and we have confidence in the traits they express. But we’ll have to wait until harvest before deciding which ones to go with,” he says.

- For more information on Climate FieldView and to sign up for the trial, visit https://cropscience.bayer.co.uk/fieldview/

Partners in performance

Partners in Performance is the result of a long-standing collaboration between Bayer and a group of progressive growers.

It started in 2011 with the launch of Aviator Xpro when growers were invited to trial Aviator on their farm. In these split-field trials Bayer took a back seat with the only demands being the field area for fungicide comparison and crop yield verified over a weighbridge or via combine yield monitor –– everything else was down to the farmer.

Over time this has developed into a club. Each year the farmers meet to discuss results, listen to guest speakers and debate winter wheat management issues.

Farming has always been a challenging business, and with Brexit those challenges have intensified. The margin between profit and breaking even is likely to become even tighter and any incremental gain will be needed for sustainable combinable crop production.

To achieve that the industry needs to work together to share the latest research and thinking, exchange ideas and experiences.

Partners in Performance aims to bring farmers and specialists together to develop solutions to improve crop performance and investment return.