AHDB has recently updated industry guidelines for sulphur in OSR. CPM takes a look at turning this into practical farm advice.

14% of farmers are still not applying any sulphur to OSR.

By Rob Jones

Turning the latest AHDB-funded work on sulphur into practical farm advice requires consideration of application rates, an understanding of soil type and thinking slightly differently about supplementary sources, says Allison Grundy of CF Fertilisers.

Latest results from AHDB-funded and ADAS-led research into the sulphur requirements of oilseed rape suggest current recommendations are not too far off the mark but more growers need to heed the advice and use this vital element in their crops, she believes.

“The results are encouraging and show that while there’s a case for revising application rates slightly, we haven’t been underestimating sulphur needs to any significant degree over recent years. Those that are already using sulphur and following industry guidelines can be reassured they’re using it effectively and likely to see significant benefits and, by and large, they don’t need to apply more.”

But the real issue is still the number of growers in the UK who are using no sulphur at all, highlights Allison.

“The British Survey of Fertiliser Practice for 2017 shows that 14% of farmers are still not applying any sulphur to OSR. Although there’s evidence average OSR yields in the UK have risen a little recently, they haven’t changed significantly since the 1980s. The gains seen in AHDB Recommended List trials since then haven’t generally been reflected in the field,” she says.

“The OSR area has grown substantially in the last 30 years reaching a peak of 756,00ha in 2012 and is now at 563,000ha. Although rotations have widened since the neonicotinoid ban, which could account for the recent yield increase, frequency of the crop in the rotation has generally increased since the 1980s.”

While this explains some of the yield challenge, it’s only one factor of many, including soil management, weed and disease control and nutrient use, she says.

“It can’t be ignored that at the same time OSR has taken off in the UK, the amount of sulphur deposited from the atmosphere has being reducing significantly.”

In previous years land could benefit from the equivalent of 80kg SO3/ha falling from the sky but following the UK’s widespread industrial clean up, it’s now little more than 7kg/ha, she points out. “OSR is particularly sensitive to sulphur deficiency, with lighter soils in areas of high rainfall and low atmospheric depositions being especially susceptible.

“Sulphate, the form of sulphur taken up by crops, is soluble in water just like nitrate and is therefore easily leached. Deep silty or clay soils are less vulnerable but, in most cases, they still require additional sulphur to protect yield and quality.”

According to ADAS soil scientist Dr Lizzie Sagoo, the new work has uncovered interesting insights into optimum sulphur use in OSR and the way this varies for different soil types.

“The response experiments were carried out at eighteen field sites across the country between 2011 and 2017. Recorded yield responses to sulphur fertiliser ranged between 0.1t/ha and 4.4t/ha, with the optimum economic rates at the sites varying between 30kg and 79kgSO3/ha.

“A range of varieties were used with no evidence to suggest that modern, higher-yielding OSR varieties require higher sulphur application rates.”

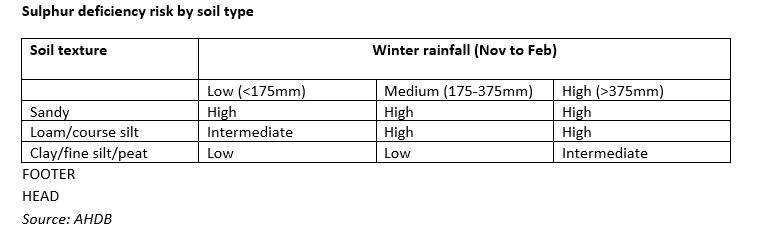

All of the sites showing a yield response had light or medium-textured soils, such as loamy sand, sandy loam or sandy clay loam soils. “Soil texture and winter rainfall were found to be a more reliable predictor of sulphur deficiency than simple soil analysis or tissue testing,” comments Lizzie.

As a result, researchers are suggesting the guidance for sulphur application to OSR is updated to include soil texture and winter rainfall as factors when assessing the risk of S deficiency.

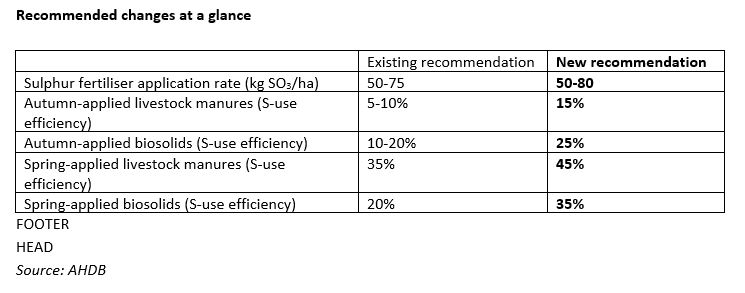

“As OSR at some sites responded to a slightly higher sulphur rate than the current 50-75kgSO3/ha recommendations, we believe the range should be extended slightly to 50-80kgSO3/ha.”

The results also show that OSR uses sulphur from organic sources more efficiently than previously thought, Lizzie explains. “Overall we believe that sulphur-use efficiency values associated with autumn applications of organic materials should be updated for OSR. These should increase to 15% for livestock manures from the current 5-10% and up to 25% for biosolids from the existing 10-20%.

“The work also suggests that the sulphur-use efficiency values for spring-applied slurry and biosolids should be increased for all crops from 35% to 45% and from 20% to 35%, respectively.

According to Dr Sajjad Awan, who manages nutrient research at AHDB, the work represents a valuable update to the original work on sulphur.

“The recommendations for sulphur use were first published in RB209 in 1994. Since then, deposition from the atmosphere has decreased dramatically and the yield potential of modern varieties has increased,” he says.

“The assumption has been that modern OSR production needs much more sulphur than the official recommendations suggest. Our research found this isn’t true and the current recommendations are not a million miles away from where they need to be.”

Previous AHDB-funded research determined how sulphur from organic materials contributes to winter wheat’s requirements, but the new work has now quantified its contribution to OSR, he points out.

Allison says balancing the nutritional value of organic manures with the appropriate fertiliser choice should be encouraged, as long as this doesn’t compromise the cost-efficiency of crop production.

“At the end of the day, crop efficiency is about maximising output at the minimal cost possible without compromising environmental concerns. As such, the priority is to optimise cost per tonne of production rather than reducing costs simply for the sake of it.

“There’s an obvious balance to be struck between use of farm-produced resources, such as FYM, and other bought in organic materials with bagged material, such as sulphur-containing granular compounds or blends.”

But she believes the key is for growers to make this balance work in their favour. “As well as focusing on optimising use of organic materials, it’s important to use the most effective sources of inorganic material to make the two forms work to their optimum potential. The sulphur used in blends is usually in the form of granular ammonium sulphate, which is very different in size and density to the urea or ammonium nitrate it’s usually blended with. This can lead to poor spreading and inaccurate distribution of nutrient, resulting in crop striping and reduced yield,” comments Allison.

“Blends are physical mixes so there’s a real risk of the various particles separating out and being distributed unevenly across the field, negating any benefits of carefully calculated application rates.”

With a true granular compound, such as DoubleTop (27N (30SO3) or SingleTop (27N (12SO3), it’s a very different situation, she explains.

“The constituent nutrients are granulated into each fertiliser particle, so that every granule contains the desired analysis of nutrients. The granules are also of a consistent size range, so they spread evenly across the bout width.

“Not only does this ensure plants receive the right amount of nutrients for optimum uptake and growth, it also minimises leeching risk from nitrogen and sulphur,” she says. “In OSR the most practical time to apply sulphur is the first or second application in early spring, towards the end of Feb to early March.”

Why sulphur is important in OSR

Sulphur helps develop and activate key enzymes and vitamins in the plant and is an essential structural component of two of the 21 amino acids that form protein. It’s also used by plants to produce the all-important oil content.

A plant takes up sulphur as it uses nitrogen, but unlike nitrogen, it’s not mobile in the plant. Crops require a sustained source of sulphur from the soil throughout the growing season.

In OSR, deficiencies can often be seen as a whitening of new flowers – they simply don’t have the rich yellow colour expected of the crop – but soil type can often be an indicator of likely problems, too.

Lighter soils in areas of high rainfall with low atmospheric depositions are especially susceptible to sulphur deficiency due to leaching. Deep silty or clay soils are less vulnerable but, in most cases, sulphur is still needed to protect against yield and quality loss.