Atlantis is the UK’s most widely used in-crop herbicide of recent years, but good stewardship has always determined its performance. CPM tells the story of one of weed science’s most significant discoveries.

Right from the word ‘go’, we knew we had a winner – this was the rat’s pyjamas.

By Tom Allen-Stevens

Can you remember the first time you witnessed the power of Atlantis (mesosulfuron+ iodosulfuron)? Chances are, you’d never seen such an effective blackgrass herbicide. And there’s a good chance you never will again.

“We called it the ‘wow’ effect,” recalls Bayer’s Dr Klaus Kӧtting, who from the mid-1990s was project leader on the Mesomaxx project that brought Atlantis to market.

“You’d take a colleague, researcher or distributor to a plot that had been treated with mesosulfuron and that’s what they’d say. No one had ever seen such performance before.”

It’s a sentiment echoed by Dr Stephen Moss, recently retired from Rothamsted Research. “The level of control really was remarkable. It looked like obliteration of blackgrass and while this was certainly impressive, it was almost too good – it could lead you to believe you’d solved your blackgrass problem.”

And this was something of which Bayer UK development manager Gordon Anderson-Taylor was only too aware. “The trials guys loved it because there were hardly any blackgrass heads they had to count in the treated plots. For us, it wasn’t a question of selling this product – it sold itself. The bigger job was stewardship.”

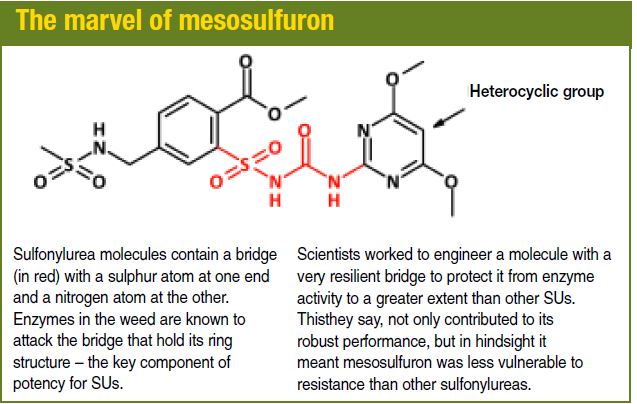

But the ‘wow’ effect of mesosulfuron was less than half the story. Dr Lothar Willms became group leader responsible for herbicides at Hoechst, that was to eventually become Bayer, in the 1980s. “The potent properties of sulfonylurea (SU) chemistry had been known for some time. We developed some new compounds, such as amidosulfuron (included in Chekker),” he recalls.

Making it safe

“We also developed a number of very effective graminicides, but the difficulty with developing a grassweed herbicide for cereal crops is making it safe, so that it selects out the weeds and leaves the crop unharmed.”

At the time, the active under investigation was the ACCase herbicide fenoxaprop. “It was a remarkably effectively graminicide, but also damaged the host cereal crop. So we set about developing a safener.”

This is a chemical that’s formulated with the active ingredient – a sort of catalyst that helps a plant break down a herbicide so that the product is harmless, but it’s only activated in the host crop, not in weed species. “The concept wasn’t new – there are safeners that had been developed for pre-emergence herbicides. But it had never been done before in post-emergence cereal graminicides,” notes Lothar Willms.

“A screening programme was started. It was huge – we must have looked at over 120,000 different molecules. A lot of people said it could never be done, that it would be impossible, but we persisted.”

Then, one day in 1989, the scientists got the breakthrough they were looking for. “We came across this one compound – mefenpyr-diethyl. It was the prefect safener for fenoxaprop and reduced crop damage from 80-90% to 0%. It was a remarkable discovery.”

The resulting product was sold as Puma and Cheetah, for example, and remains one of the most successful cereal graminicides of all time. But the development team then turned its attention to the SUs. “Many thought this safener was tailor-made just for ACCase products. But we set up a screening model with some very strong SU material using mefenpyr-diethyl,” continues Lothar Willms.

“The results were astonishing and we very soon realised we had the breakthrough we needed – a safener that worked with SU chemistry.” It was combined first with iodosulfuron – an active noted for its efficacy on dicot weeds, that also offered grassweed control.

“It was an interesting start, so we took in more compounds. Then in 1993, we detected mesosulfuron. I’ll never forget the day I saw the results of the first field trials – it was 1994 in a plot where the untreated control had over 1000 blackgrass plants/m², but the Mesomaxx controlled every one perfectly and the wheat was unscathed.”

Significant resouce

At the time, it wasn’t actually mesosulfuron the herbicide team had pinned its hopes on, however. “We were bringing on a sister compound and channelling significant resource into its development,” notes Klaus Kӧtting.

But mesosulfuron was no accidental discovery, he points out. “It was engineered by a group of chemists looking specifically at how to manipulate molecules that would be taken up by blackgrass and then persist in order to develop their full efficacy.” (see diagram on pxx).

So in Nov 1996, the project team switched its focus to mesosulfuron, and then looked at combining this with iodosulfuron. “This active was launched in 1998 – a leading brand was Hussar, with good efficacy on dicot weeds. It also had an effect on some grasses so we tried it in combination with mesosulfuron and the safener, and there was a synergy – it was a second ‘wow’ effect,” notes Klaus Kӧtting.

In effect, the project team had made not one important discovery, but three – the powerful potency of mesosulfuron, the synergy iodosulfuron brought in and the remarkable reliability of the safener technology. But that in itself created a huge regulatory challenge, recalls Achim Zöllkau, who joined the team as the dossier was submitted for approval in 2000.

“There had already been considerable investment in this herbicide, and the parent company had passed through restructuring changes, from Hoechst, to Aventis CropScience to Bayer. And we had huge challenges ahead of us, with environmental fate investigations for an SU herbicide that was to be used both in autumn and spring, for example. To get this through its final stages we needed researchers who had the ‘Columbus gene’, because this was unknown territory, and we needed even more investment.

“But the discovery team stuck together like glue, and what carried the product through was the ‘wow’ effect – it gave everyone the confidence to invest, commit and persist. Because we knew this had the potential to change the herbicide market.”

Atlantis was launched in France in 2002. It was a major product launch but needed little publicity. “Growers had already heard about it or seen it in trials and were really excited about it. There was a rumour that German farmers even crossed the border to get their hands on the chemistry a year early, although this was never confirmed.”

It was launched in the UK in 2003 and quickly became the most widely used in-crop herbicide – it’s been applied to nearly seven million ha of UK wheat since then. At its peak in the 2007/08 growing season, Atlantis was applied to over 824,000ha, or 40% of the UK wheat area.

This popularity presented a further challenge, however, recognised even before Atlantis came to market. “How could we safeguard the power of this product? By its nature, the technology is vulnerable to resistance,” notes Achim Zöllkau.

Unknown territory

Once again, the project team was steering into unknown territory. “We had to manage the stewardship of Atlantis. There was the internal perception as well as to how growers would perceive it. Historically, there had been a certain amount of denial mode within the agchem industry we needed to confront.”

Previously, some people within the industry had been reluctant to talk openly about weed resistance for fear this would affect product sales. But Bayer took a longer-term view with Atlantis, he points out, realising the commercial potential, as well as the benefit for the industry as a whole, would be greater if careful stewardship extended the life of the product.

But there was still the grower perception to address. “There was this expectation that, just as a product began to lose its efficacy, manufacturers would magic up another. We needed to overcome this simplistic view, because we knew it would be way more than the standard five years before this chemistry would be superseded.”

In the UK, that responsibility fell to Gordon Anderson-Taylor as well as to Nick Duncan, who was project manager for 04H, as Atlantis was known before its launch. “Right from the word ‘go’, we knew we had a winner – this was the rat’s pyjamas,” remarks Nick Duncan. “It was dynamite stuff in our own demonstration plots, as well as those conducted by independents.

“But right from the start we talked about resistance. We were very open and honest about it– chemistry with that efficacy allows growers to take the easy path and that would result in blackgrass developing resistance to Atlantis very quickly. At the time of its introduction, however, the whole industry had got its head round stewardship. We didn’t magic up best practice guidelines as these had already been established by WRAG (Weed Resistance Action Group). We used the strength and power of Atlantis and channelled considerable resource into promoting the guidelines and helping growers adopt them.”

No one was better positioned to address these issues with growers than Dr Stephen Moss. “Bayer handled Atlantis a lot better than some other herbicides had been in the past – there was no industry denial,” he notes. “Work we’d done with flupyrsulfuron showed resistance would develop, and experience worldwide suggested this could do so quickly.

“But this was quite a new situation – a strong ALS inhibitor with very impressive activity. We weren’t sure whether enhanced metabolism or target site resistance would be the biggest threat, and in a way we were both right and wrong with our early projections.”

He’d witnessed Atlantis’ efficacy that looked like 100% control. “But it can’t have really been 100%, otherwise resistance could not have evolved. Just one plant that escapes control has the potential to build a resistant population by roughly ten times each year. You won’t see it for several years, but suddenly you realise you have a resistance problem.”

So resistance was virtually inevitable in a weed like blackgrass, he argues. The skill for the grower is to adopt practices that reduce reliance on the chemistry to slow down the timeline. “Weed resistance isn’t a product of ignorance – most farmers have an impressive understanding of the practices needed to minimise its development, but putting those into practice is difficult.

Irresistible

“Atlantis was the easiest way for farmers to control blackgrass in the short term, which made its use too irresistible. How effective it is now in individual situations depends on a farmer’s ability to turn their understanding of resistance into on-farm practice.”

Atlantis was the first herbicide to include detailed resistance-management guidelines on the product label, points out Gordon Anderson-Taylor. These include:

- Always follow WRAG guidelines

- Use Atlantis in mixture or in sequence with non-ALS herbicides

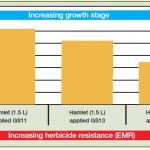

- Apply as early as possible, ideally before GS31

- Don’t rely on Atlantis as the sole means of control in successive crops

- Use different, non-ALS modes of action throughout the rotation

- Monitor and investigate patches of poor weed control.

Evidence suggest growers have always used robust rates and partnered the product with the adjuvant Biopower – measures that improve efficacy and help against resistance, he says. But other practices have been resisted.

“We’ve always struggled to get growers to put Atlantis on early enough. It’s understandable, because you might not want to spend on the product until there’s evidence of a problem. But bigger weeds are much harder to control, and more likely to resist the application.”

Autumn is therefore the best timing, and approval was sought for this during product registration specifically for the UK market, he notes. “Over the years, no more than 40% has been applied before Christmas, and it’s currently more like 20-25%. But today’s later drilling means a Feb application is often suitable for many wheat crops, provided blackgrass is still pre-tillering.”

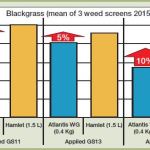

The product has been through several iterations over the years – an oil-dispersible formulation is available (Hatra, Horus), for example, and diflufenican (DFF) has also been formulated with Atlantis. Initially, this was available as Othello, which offered improved activity on annual meadowgrass. New last autumn was Hamlet, giving growers an extra 5-10% step-up in control of blackgrass over straight Atlantis, notes Gordon Anderson-Taylor.

“The big challenge was to formulate DFF with mesosulfuron and iodosulfuron. DFF is a very useful active that depends on its partner. Get the formulation right and you have a product that is more than the sum of its parts, and that’s why Hamlet works – it’s our expertise and considerable experience with DFF that’s proven successful.”

Launched by Rhone Poulenc in the 1980s, DFF has always been a product noted for its broadleaf-weed activity. It’s naturally a pre-emergence or early post-emergence product, that acts on the developing or emerging coleoptile and tackles a broader range of weeds than pendimethalin.

“It was the ideal partner for isoproturon, used early post-em,” recalls Gordon Anderson-Taylor, who was development manager for DFF in its early days. “Not a lot can touch it on broadleaf weeds, and it does have useful activity on grassweeds. That’s why it goes so well with flufenacet in Liberator.”

DFF’s value in the early slot positions Hamlet as a product best applied in autumn or very early spring. Numerous trials have delivered 5-15% extra control over Atlantis, he says, with 5-10% a realistic expectation. “This holds for resistant blackgrass, even at GS23, but overall control drops off the later you apply it.”

Further product developments will be released from 2017-20, including a formulation specially designed for spring application. These will ensure improved control of blackgrass, he assures, but there’ll be no ‘wow’ effect.

“The very fact that Atlantis is still a market leader and the most effective post-emergence product after 14 years is way beyond the expectations we had at its launch, and testament to the power of the herbicide,” says Gordon Anderson-Taylor.

“But what’s also impressive is the attitude of growers – there’s a good understanding now of resistance and adoption of responsible strategies that rely less on the chemistry. That’s a healthy environment to have, should there be any new product developments.”

Stephen Moss feels waiting for that next big herbicide could be like waiting for ‘jam tomorrow’, however. “You could be in for a long wait, and would you see that ‘wow’ effect again? Even if you did, it probably wouldn’t last, so the main message is to adopt a blackgrass control strategy in which chemistry plays an important, but smaller part.”

Managing the ‘silver bullet’

Chris Tolley recalls the excitement about Atlantis a year before it was launched. “People were taking about it well before its introduction. Back then, everyone would’ve read about it in the farming press and expected that this new product would be big help – and it was.”

The younger half of a father and son team farming 320ha in Leics, and with a BASIS diploma in agronomy, he looks after the agronomy for the whole farm which grows winter wheat, barley, oats, oilseed rape and spring barley on sandy clay loam to clay soils. There’s a fairly typical weed spectrum that includes blackgrass, so Chris Tolley and his father both remember the difference Atlantis made.

“Before, we relied on clodinafop, trifluralin and isoproturon to control blackgrass – these were working but were losing efficacy,” he says. “Atlantis came at the right time and was an obvious step-up.

“When it was first introduced it gave nearly 100% control even against fairly big plants in spring. I think many of us saw it as a ‘silver bullet’ because you could use it alone or in a mixture and do a good job in autumn or spring.”

Atlantis was so effective at the start that few anticipated the capacity of blackgrass to evolve to the challenge of mesosulfuron, he reckons. “The way we talked then was like Atlantis was going to continue to provide good control forever, there wasn’t really any consideration of the resistance risks because everyone was so pleased with the product. I can’t remember resistance being a big top of conversation among farmers at the time.”

But with the benefit of hindsight, this was a mistake, he says and he believes that were a new product to come out now, things would be different. “I think farmers’ attitudes have changed sufficiently that people would continue doing the cultural techniques to maintain control, even with a new silver bullet.”

Grain prices were low in the early years of Atlantis, he adds – in the £60-£80/t range – so it was seen as a way to cut costs for wheat by saving on pre-emergence herbicides and costly cultivations. What’s more, wheat could be sown early to maximise yield without the worry that blackgrass would take over.

Nonetheless, Chris Tolley continued with cultural techniques when Atlantis was first introduced and is still getting decent control. “We do as much as possible before reaching for the can – we’ve always used rotational ploughing and Atlantis didn’t change that.” In addition to ploughing, blackgrass mapping, hand rogueing and spray plans tailored to specific field sections are used to keep weeds at bay.