There’s a premium market available for growers of Group 2 varieties, but only if you can achieve the right quality criteria. CPM visits a Beds milling wheat grower to find out how.

There’s a premium market available for growers of Group 2 varieties, but only if you can achieve the right quality criteria. CPM visits a Beds milling wheat grower to find out how.

The varieties I choose must ensure we maintain a consistent performance.

By Tom Allen-Stevens

It’s the day after the Easter break, and Andrew Robinson has just about abandoned any hope of getting his spring beans established. Over the weekend, more than 30mm of rain has fallen on the already sodden Hanslope series heavy clay soils that make up the majority of the 1150ha farmed by Heathcote Farms, based at Herne Manor Farm near Toddington, Beds.

“We always grow beans, but they must go in by the third week of March and they must bring a decent yield – anything below 4.2t/ha and you’re losing money. What’s more, there’s no point in mauling them into land that won’t then make a decent seedbed for the following crop,” he says.

BREAKING NEWS: Rank Hovis has milling success with new Group 2 wheats

So the several tonnes of seed he has probably won’t be planted. Instead he’ll wait for the land to dry out, “flick it over” and plant a cover crop. “A good crop of beans is a beautiful entry for milling wheat. But a bad crop is worse than no crop at all, and you should not do anything to compromise the main cash crop.”

The farm moved its 500ha of wheat completely over to milling varieties around five years ago. It makes Andrew Fit for the Future – set up to grow wheat for a market with good prospects, and with a strategy for growing it that brings strong returns. At Heathcote, the wheats alternate with oilseed rape on the clay, with the beans slotting in one year in six. On 220ha of lighter Greensand at Liddlington, winter barley comes in with the OSR in a three-year rotation.

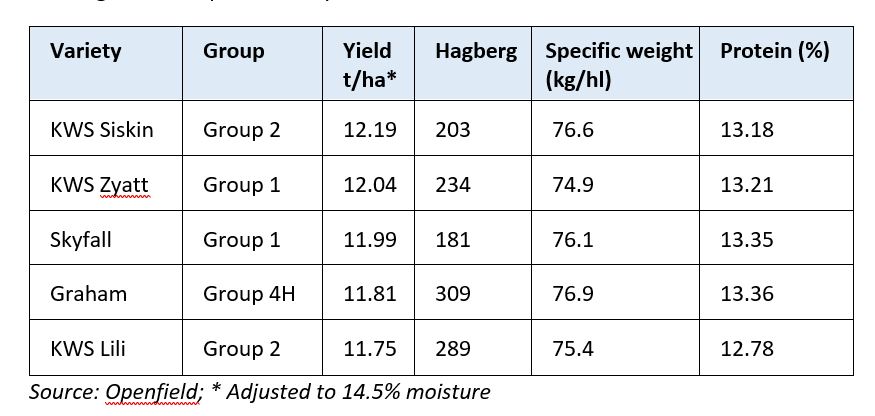

“For the past five years we’ve carried out wheat variety trials – Openfield supply the seed for 18 quarter ha plots,” Andrew explains. “We manage them, so we get an

accurate idea how the varieties perform on this farm. The milling varieties have always come top – not only that, but the gross margin’s better.”

In 2017, it was Group 2 KWS Siskin that topped the trials. “We first had the variety in trials three years ago. Back then it was a coded line but it caught my eye because it had a thousand grain weight of 63g. It yielded well, too.”

The variety came near the top of the trials in 2016 and Andrew included 92ha in the farm’s wheat portfolio alongside Group 1s Crusoe and KWS Zyatt for the 2017 harvest. “Siskin’s absolutely robust and it’s aggressive in autumn, too,” notes Andrew.

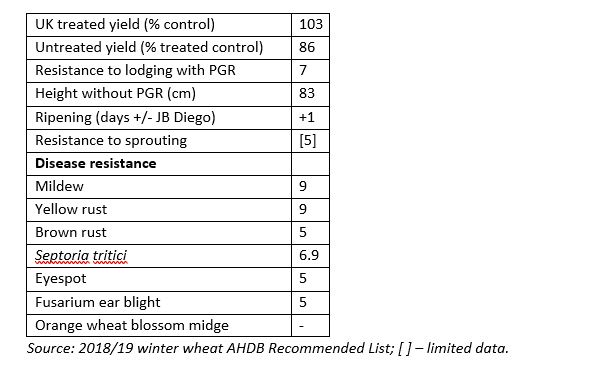

All the varieties in the trials were clean, but you couldn’t find a spec of disease on KWS Siskin.

“Its stand-out, though, is the disease performance. All the varieties in the trials were clean, but you couldn’t find a spec of disease on Siskin.”

This is coupled with premium potential that goes hand-in-hand with its yield performance. “The Group 2 market’s not big. Cordiale’s seen as its leading quality variety and you do wonder whether Siskin will be the next Cordiale,” he says.

“But the varieties I choose must ensure we maintain a consistent performance, not just in terms of yield, but quality too. I like to supply the local market and we have plenty of mills in a 40-mile radius. I want us to be a preferred supplier, so a merchant knows that every load that comes from us is the right spec.”

But there’s a caveat. “That should be worth a minimum of £15/t for a Group 1 type. The grower takes the risk, the added expense, in terms of extra N and grain-drying costs, and the extra management, so there has to be a reward.

“With Siskin, the yield makes it worth growing even without the premium. But the milling market is the one I aim for and it’s worth it, provided there’s a £13/t premium.”

With a 96% pass rate, it seems Andrew’s achieving his aim, while the AHDB Cereals Quality Survey shows just 24% of Group 1 and 2 samples made the grade in 2017 (13% protein, 250 Hagberg and 76kg/hl specific weight).

No silver bullet

So what’s his secret? “There’s no silver bullet – it’s down to appropriation of inputs and all the little things add up. But there’s one fundamental aspect that has to be right, and that’s the soil.”

Which is why he’s not going to compromise his milling potential by mauling in his beans. There’s a fastidious maintenance of drains across the farm, too, with outlets regularly checked, blocked drains promptly cleared and regular, rotational mole-draining and ditching.

Soil organic matter (SOM) gets the care it deserves, too – across the farm this varies from 6% to over 8%. That’s helped by a composting enterprise that brings in 10,000-20,000t of green waste that’s processed and rotationally spread at around 20t/ha every 2-3 years, which has improved SOM by around 2% in places.

All seed is drilled at a variable rate with the farm’s 8m Väderstad Rapid drill. “We’re aiming for 650 fertile ears/m², and on the Siskin drilled in early Oct into a dry seedbed, achieved 550 ears/m², which I’m happy with. That brings it back to a target seed rate of 375 seeds/m², but it’s surprising just how much the rate is varied over the field – there are some snotty bits of the farm where the germination was as low as 50-60%.”

The KWS Zyatt was drilled first from mid Sept, with Siskin put in the ground last at the beginning of Oct – it’s “aggressive” autumn growth ensuring plenty of leaf before the winter set in.

Trace elements get plenty of attention at Heathcote, with manganese applied to the seed and with the post-emergence herbicide. “This is a responsive farm, and it’s also important that the crop is as healthy as it can be. You find you get the odd pocket of Mn deficiency in particular if you don’t top the crop up.”

In spring, four leaf tissue tests are carried out before each spray timing to assess micronutrient requirements. “Over the years we’ve built up a database of tests and there’s now a pretty regular pattern. Aside from three Mn applications, we put on two of magnesium. Boron, zinc and sometimes copper run short – we put Bo on twice last year.”

The fertiliser is all applied as liquid, which Andrew reckons is better than solid, particularly when conditions are dry. “We apply sulphur with every dressing of nitrogen – I think it’s absolutely vital to drip-feed the S with the N.

“The first dose is applied as soon as we can travel, and I’m not a fan of a small early dressing. We make three equal splits and aim for no more than six weeks between them.”

A late dose of Nufol ensures there’s protein in the ear. “The Warburton contract precludes us from applying any to the Crusoe, but the variety seems to be good at assimilating N, and doesn’t seem to need it. I think it gets something out of the soil, and perhaps that again comes down to ensuring this is healthy with the right SOM.”

He also tends to use biostimulants as “stress busters”. “It’s year-specific – if there’s a fair bit of moisture, you’re unlikely to get a return. But they do help in a dry year.”

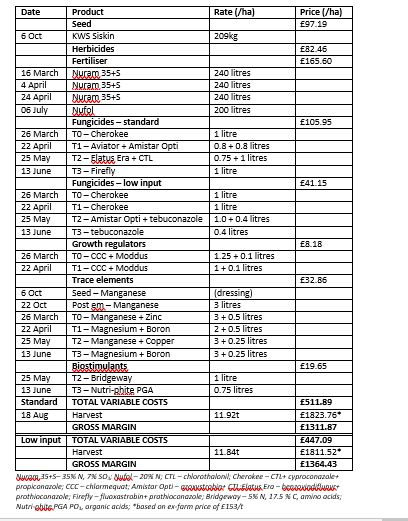

It’s the fungicide applications that brought interesting results last year, though. “One block of Siskin was split, with half the crop receiving a low input programme (see table below). There was a £60/ha cost saving but you really couldn’t tell the difference. There was no statistically significant yield difference either.”

When it comes to harvest, you can’t afford to “dilly-dally”, says Andrew. Glyphosate is routinely applied to ensure the Claas Lexion 770 with its 10.7m header can pass smoothly through the crop. “We’ll cut as soon as it’s ready, even if the moisture is as high as 24%. You need the combine and drier capacity to be able to do that.”

Two continuous-flow mains-gas driers work at up to 22t/hr each to pass the grain into 9500t of on-floor storage. “We always ensure the store is immaculately clean before harvest and it’s vital to pay close attention to condition until the grain leaves the farm.”

He sells 25-30% of this forward, with the rest over the growing year, making use of pools as appropriate. His crop rarely fails to meet the grade, but Andrew believes a better level of trust in the supply chain will come from better communication.

“I’d rather engage and understand the miller more. I think every milling wheat grower should visit a mill and every miller should make the effort to visit a farm. As we move towards Brexit, the local market will become more important, and I welcome that – I’d rather grow a crop that stays here in the UK.”

Heathcote Farms’ recipe for Group 2 milling wheats, 2017

Toddington trial top five variety results, harvest 2017

KWS Siskin at a glance

Fit for the Future

As Brexit approaches, wheat growers will be preparing their enterprise for a market without the protection of the EU but potentially open to the opportunities of a wider world. Finding the right market, and the variety to fulfil it, will be crucial for those looking to get ahead.

In this series of articles, CPM has teamed up with KWS to explore how the wheat market may evolve from 2019 and beyond, and profile growers set to deliver ongoing profitability.

KWS is a leading breeder of cereals, oilseeds, sugar beet and maize. As a family-owned business, it is truly independent and entirely focussed on promoting success through the continual improvement of varieties with higher yields, strong disease and pest resistance, and excellent grain quality. We’re committed to your future just as much as you are.