Growers looking to maximise the efficacy of their herbicide “stack” in the fight against blackgrass are increasingly turning to a herbicide molecule first used in the UK in the 1960s. Avadex Excel 15G has seen a huge increase in new and “second-time around” users over the last seven years and now there’s a liquid version as well.

In the same year the Russian cosmonaut, Yuri Gagarin, became the first person to orbit Earth, the herbicide Avadex became available. CPM finds out why it has endured and how to get the best from it.

63% of the products applied for blackgrass contain flufenacet.

By Lucy de la Pasture

Very few active ingredients have been on the market for as long as the molecule contained in Avadex Excel 15G, which has a 56-year track record. Formulated as a granule and requiring bespoke application, the usage of Avadex has wavered in popularity over the decades it’s been available. This was particularly the case in the years where new herbicides came along like London buses and actually did a good job.

But then blackgrass got the upper hand and every little bit of control began to count in the effort to reach the magic 97% control needed to keep this exceptionally competitive grassweed in hand. Older chemistry was revisited and the herbicide ‘stack’ was born.

Today Avadex and flufenacet form the basis of the stack. Gowan’s technical manager Rob Plaice explains how to maximise its performance.

What is Avadex?

Avadex contains tri-allate, a member of the thiocarbamates chemical family and classified as Group N by the Herbicide Resistance Action Committee. It works by inhibiting the lipid synthesis of target weeds, disrupting the biochemical pathways involved in maintaining crucial structures, such as the waxy cuticle layer and the nuclear development of cells, as well as disturbing the weed’s hormonal processes.

Avadex is applied to the soil to form a chemical barrier and is taken up by the coleoptile as weeds emerge through this herbicide layer. As a result of its mode of action within the weed, tri-allate is effective in inhibiting cell division and elongation in shoots before emergence from the ground and causes abnormal emergence of leaves from the coleoptile. The growth of susceptible weeds which do manage to emerge is often stunted, with cupped or crinkled leaves.

Avadex is active on most grassweed species, including blackgrass, ryegrasses, wild oats, brome species and annual meadowgrass when applied pre-emergence of both the crop and the weed, which needs to grow up through the herbicide layer. Some useful control of broadleaf weeds complements its effect on grassweed species, with some activity on speedwell, deadnettle, forget-me-not and anecdotal evidence of activity on poppies on cleavers, which show stunted symptoms and are at least ‘held back’.

Why is it useful?

Blackgrass has developed resistance to a number of different herbicides, with target site resistance to the ACCase and ALS-inhibitor herbicides, which are the mainstay of post-emergence strategies, now prevalent.

Another type of resistance is also present in much of the UK’s blackgrass population. Enhanced metabolism resistance (EMR) results in herbicide detoxification and is the most common resistance mechanism in blackgrass, affecting most herbicides to varying degrees.

Because post-emergence herbicides are quickly becoming less reliable, most blackgrass herbicide strategies are heavily dependent on flufenacet (HRAC Group K3) – 63% of the products applied for blackgrass control in the UK contain flufenacet in combination with different ai’s.

Avadex provides an alternative mode of action, so goes hand-in-hand with flufenacet as part of a blackgrass herbicide strategy. It makes weeds more susceptible to any subsequent herbicide treatments, as well as reducing the selection pressure for EMR, which builds up very slowly in blackgrass programmes.

Why is it a granule?

Avadex is formulated with a special clay compound as a granule. The granule provides a reservoir and the clay fraction regulates the release of the active, proven to be the most reliable means of delivery.

Tri-allate is strongly absorbed onto soil particles. Formulating as a granule takes away the dependency on soil as a binding medium, ensuring performance is more consistent over different soil types. The granule releases active under all conditions, even when dry though moisture is required for optimum performance.

Is there a liquid formulation?

A new liquid formulation of Avadex is available this autumn for the first time since the 1990s, though it won’t be the panacea that those who loathe granules may have wished for.

Formulated as a capsule suspension, in which a tiny amount of the active is encapsulated in a polymer capsule just 4-5µm diameter, the liquid delivers 72% of the rate delivered in the granule. This means that at the full recommended rate of 3.6lt/ha, it’s slightly less active than its granular counterpart at 15kg/ha.

When pre-emergence conditions are good the liquid formulation works very well but it’s more affected by extremes, such as very wet or dry conditions. But the liquid is a flexible option and may be particularly useful if contractor delays are jeopardising pre-em granular application. A well-timed liquid application may work better than a poorly-timed application of Avadex granules, with the added bonus of handy tank-mix partners.

What are the typical results?

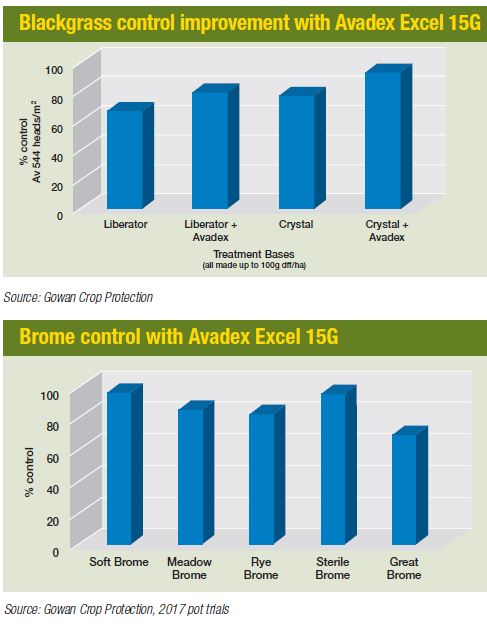

On average, an application of Avadex lifts the overall performance of the blackgrass herbicide stack by 15-20%, with performance of the liquid formulation lagging slightly behind.

But blackgrass isn’t the only weed that Avadex is effective on. Brome control in barley is particularly difficult, with no real post-emergence options available. Avadex provides good control of brome species, a weed which mostly emerges in the autumn.

For all weeds, a number of factors are necessary for best results. A firm, consolidated seedbed is optimal and Avadex shouldn’t be applied to cloddy seedbeds because there’s a risk the herbicide could come into contact with wheat seed and affect emergence. Wheat seeds need to have 4cm of soil coverage for safe application.

Soil moisture after application is necessary to activate the herbicide, so results won’t be as good when soil conditions remain dry and blackgrass has emerged before rain arrives.

Timing is absolutely crucial and must be pre-emergence of both the crop and the weed. That means it’s advisable to get the application on as soon as possible after drilling.

What are the key points on application?

The quality of application is as important to getting the timing right, with an even distribution of product on the soil surface the prime aim. That means keeping metering mechanisms, distribution pipes and deflector plates on application machinery in good order between NSTS tests.

The NSTS test checks the fabric of the granule applicator; the pipework, fan, air pressure but it doesn’t look at the pattern of distribution of granules on the ground. It makes sense if money is being spent on herbicides tackling the biggest weed threat of our time, to make sure granules are being applied through equipment where the pattern of spread has been evaluated – whether applying through contractor or own machinery.

Deflector plates set the pattern so make sure they’re not bent or twisted and get a patternation test where unsure. A list of contractors can be found at www.Avadex.co.uk, and Gowan encourages any contractors who wish to be added to the list to get in touch.

What brings best performance?

A wide range of operations can apply Avadex, from a bespoke operation to an applicator mounted behind the drill or rolls. Whatever the means of application, it’s important to remember that operators need to be PA4G qualified.

There are potential pitfalls to avoid if the applicator is mounted on other equipment. Forward speed needs to be watched, as above 10km/h the spread pattern may be compromised, leading to uneven distribution on the soil surface. When mounted on the rolls, avoid rolling the granules down towards the seed to avoid any potential emergence problems.

A further option for Avadex application is with Omex suspension liquid P and K fertilisers using specialist sprayers. The viscosity of the liquid fertiliser ensures the Avadex remains evenly distributed within the tank-mix, without settling or floating. This enables accurate application at up to 36m widths.

If soil conditions are very dry after drilling, it’s best to delay Avadex application for a few days – the drilled crop and weed seeds won’t germinate under extremely dry conditions so there will be a slightly wider application window.

Timeliness is everything for Lincs grower

David Shucksmith and his cousin, Stuart, run a 327ha farming partnership near Louth in Lincs. Spring crops already feature in the rotation, with spring barley and beans supplementing winter crops of wheat and oilseed rape.

While not over-run with blackgrass, the farm has its fair share to deal with and Avadex has been an integral part of their control strategy since 2008.

In its first year, the Avadex was contractor-applied but problems with timeliness led the cousins to make the decision to take matters back into their own hands and purchase an applicator of their own. It was an obvious next step to start contracting, explains David Shucksmith.

“Avadex is an essential ingredient in a blackgrass control strategy. The way it effects the blackgrass means that in combination with any autumn residual program, it brings an uplift in control,” he says.

One of the weeds that David Shucksmith has noticed Avadex has a marked effect on is cleavers. “Since first using Avadex in 2008, we’ve never had to over-spray for cleavers. Avadex seems to control many of the spring-germinating weeds, gives excellent control of wild oats and really assists with brome control,” he says.

“Winter and spring barley and winter wheat have a full label approval for Avadex, all pre-emergence of crop and weeds. EAMUs are available for winter rye, triticale, linseed, miscanthus and canary seed, with further label extensions hoped for,” he adds.

The partnership runs two 24m Bateman machines, a HiLo and an RB15, which has hydraulically adjustable axles. The custom-designed Lite Trac granule applicators have been carefully designed to operate along the sprayer boom. Distribution and metering all had to be developed, and four electrically driven metering rollers were chosen to give the required degree of accuracy, he says.

“We decided on 16 outlets over the 24m boom, with section control covering four, 6m-wide boom sections. The spread pattern we achieve reinforces that the applicator delivers what we set out to achieve,” he explains.

David Shucksmith is careful not to overcommit and risk under-delivering where his contracting operations are concerned. Since 2009, the contracting operation has treated over 31,000ha, 90% of which was with Avadex.

Accuracy of application is something he takes very seriously, making sure his applicators are checked every year by SCS (Sprayer and Spreader Testing). The self-propelled applicator maintains its accuracy through a Star Fire auto-steer system.

“The change in Avadex label last season saw the introduction of a 10m aquatic buffer zone for all crops and a removal of post-emergence application to cereals, requiring all Avadex to be applied pre-emergence, further tightening the application window,” he notes.

With his two machines, he’s able to offer very timely application in a very narrow application window, recognising that timely application is everything where Avadex is concerned.

“The last thing I want to do is to let down my customers and miss the timing in the same way I was let down the first year we used Avadex,” he adds.

Avadex – maximising performance of the stack: top tips

- Ensure accurate and even application – make sure applicators have been NSTS tested and have had their spread pattern evaluated.

- Timing is very important – the active ingredient is taken up by the shoots of weeds so needs to be applied before they germinate.

- Use as part of an integrated control strategy – Avadex will boost performance of the herbicide stack if used correctly but shouldn’t be a stand-alone treatment.

SPONSOR MESSAGE

The Gowan Company was started over 50 years ago in Yuma, Arizona by Jon Jessen and he’s still active in the business every day, travelling the world meeting growers and looking for new opportunities. His eldest daughter Juli is CEO of the family-owned business. Gowan entered the UK market in 2004 after taking over the well-known Avadex (tri-allate) herbicide from Monsanto.

The business has grown steadily over recent years, gaining a reputation for developing and maintaining important active substances for growers all over the world. In the UK the product range is increasing and encompasses potato blight products and graminicides at the moment.

Gowan’s International business is now headquartered at the world-renowned Rothamsted Centre for Research and Enterprise, and the UK and Ireland business comprises a team of three people with Dominic Lamb, Robert Plaice and Kuldip Mudhar having a combined 83 years’ experience in crop protection between them.