The past season has been, and continues to be, a challenge for arable farmers.

Though grain prices look buoyant, some of the benefit has been lost amid a backdrop of soaring input costs. Therefore, making every grain count is more important than ever.

Though growers are well-practiced in minimising risk of losses ahead of harvest, Ken Black, national account manager at Bayer, says grain store preparation has an important role to play in reducing post-harvest losses.

“It isn’t a popular job on farm. It’s time consuming and often needs doing during a period which is incredibly busy, but that doesn’t mean it can be overlooked. A proactive approach is needed to ensure that all the work that goes into growing and harvesting grain doesn’t go to waste.”

Ken points out that it only takes one insect to be found in a 1kg sample of grain for it to be rejected. “And, with end-users becoming increasingly selective when it comes to buying or rejecting grain, it’s vital for farmers to take a proactive approach when it comes to dealing with pests in the grain store.”

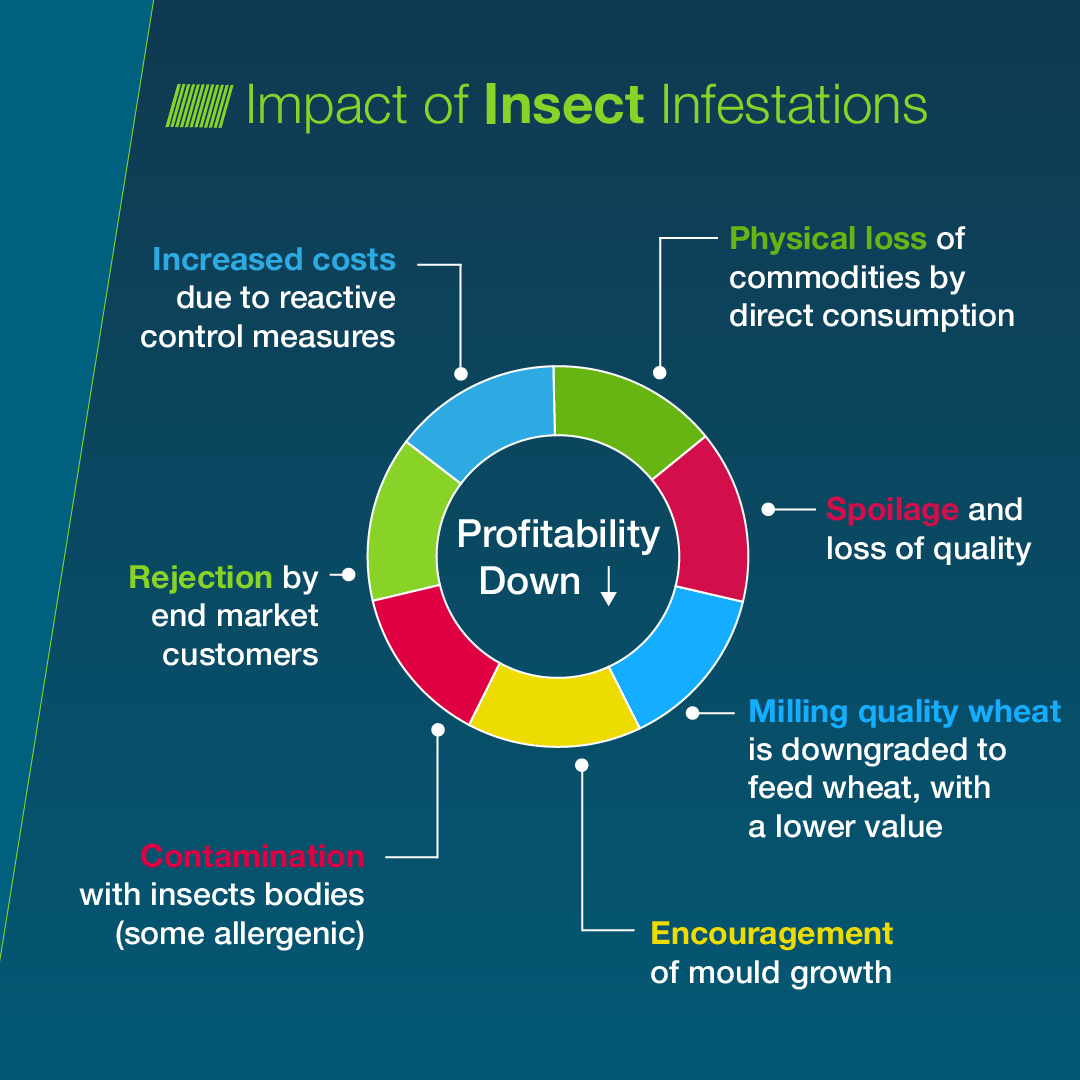

Impact of infestations

Some infestations can damage grains directly, with insects moving from one grain to the next, creating a snowball effect, he explains. “The more insects present, then the higher the temperature and moisture content within the store, attracting even more pests and ultimately causing more damage.”

Some infestations can damage grains directly, with insects moving from one grain to the next, creating a snowball effect, he explains. “The more insects present, then the higher the temperature and moisture content within the store, attracting even more pests and ultimately causing more damage.”

What’s more, the pests within a store aren’t always as well understood as those in the field, reckons Ken.

“It’s useful to understand that none of the pests enter the store from the field during the harvest, and if they did, they wouldn’t survive as they aren’t adapted to survive in the store environment. Instead, insects lie dormant on ledges or in cracks in the store, they can be brought in on machinery, on people, and on transport delivering or collecting from the farm.”

But crucially an understanding of the different types of pests and the conditions they like is required to be best able to deal with them, he says, adding that pests can be categorised into three groups: primary, secondary and tertiary pests.

“In their simplest form, primary pests – like grain weevils and lesser grain borers – have mouth parts which damage the grain. They bore into it and lay eggs, which eventually become larvae and break through ready to start the process again. Their activity raises the temperature and moisture levels too, making the grain more susceptible to other pests.

“Secondary pests – like red rust flour beetles or saw-toothed grain beetles – feed on the already damaged grain. And tertiary pests don’t damage the grain itself but in large numbers they can cause an allergic response in humans and livestock, which of course is a huge problem with end-users.”

Early preparation

To maximise protection, early preparation is key, says Ken. “A grain store should be cleaned and prepared six to eight weeks before harvest.

“The earlier you can prepare a store by thoroughly cleaning it out and monitoring for insect activity, the better. It gives you more opportunity to get it right before the grain arrives and to treat as necessary. Thoroughly clean ledges and dispose of any old dust and debris as quickly as possible, well away from the store. Don’t leave vacuums within the store as the pests can easily crawl out.”

Insect monitoring traps, which are sticky boards that can be put in every few metres, can help farmers identify any insect activity, he advises.

“If you haven’t seen any activity after monitoring you may not need to apply any insecticide. But where there is evidence, you might consider something like Bayer’s K-Obiol (deltamethrin). This should be applied up to two months ahead of harvest. Its residual effect allows you to control any adult insects that come into contact with it.”

K-Obiol is a residual pesticide which provides control of stored grain pests like beetles, weevils and moths. It’s a non-systemic product, which acts on insects via contact and ingestion, explains Ken. “In terms of dose rate, for surface treatment of grains and seeds in stacks, as well as ceilings and floors in warehouses, application recommendations for a 100m2 area are to mix 120g of K-Obiol thoroughly in three litres of water.”

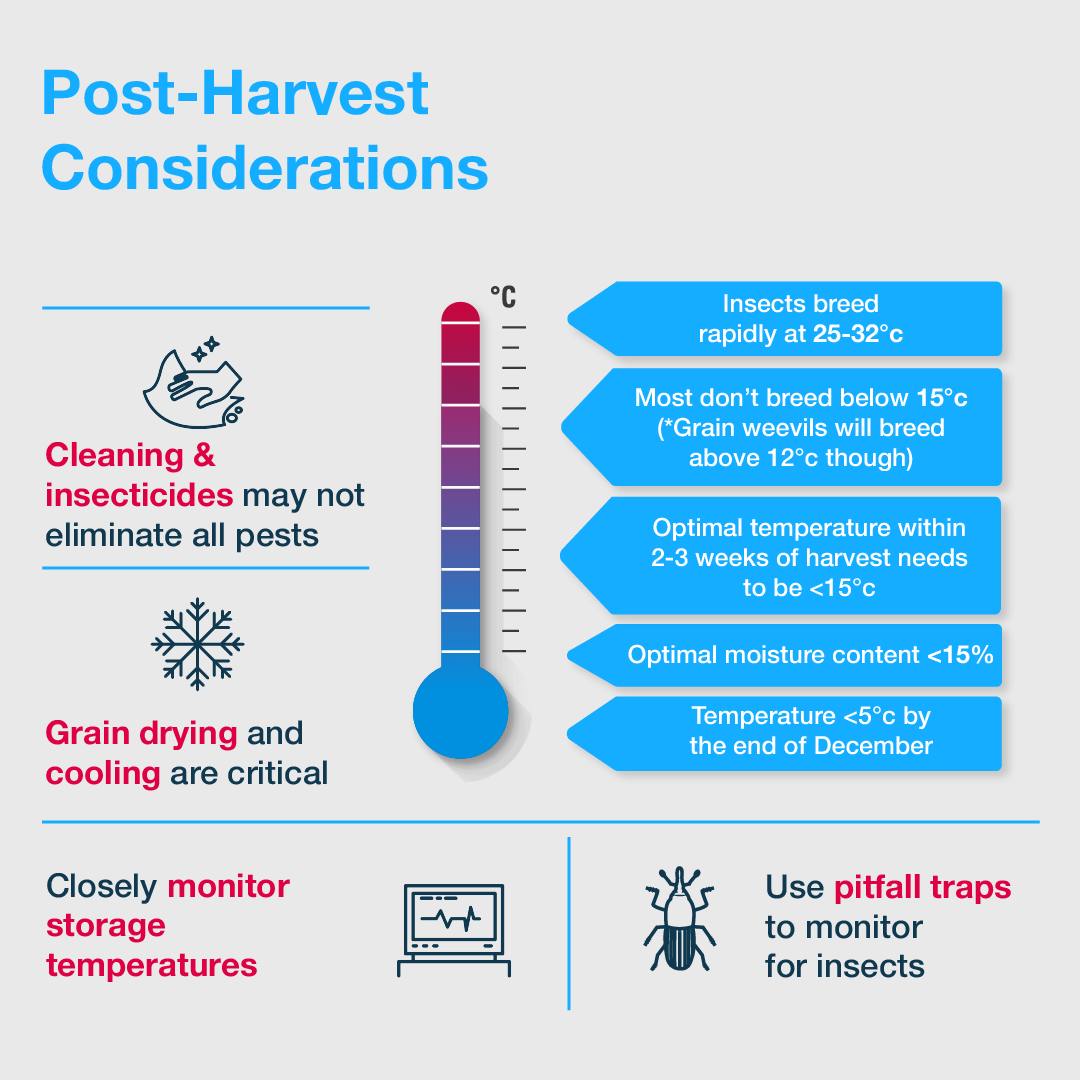

Post-harvest considerations

Once the grain is in store, it’s important to get the temperature down, cooling the grain to an optimum 15℃ or below, notes Ken. “Farmers should be looking out for hotspots, which will help to identify where insects might thrive. Pitfall traps placed at regular intervals on the surface of the grain and regular manual sieving of the grain should be carried out to see what’s there. Checking and monitoring is crucial at this stage, allowing you to act, if necessary,” he concludes.

Once the grain is in store, it’s important to get the temperature down, cooling the grain to an optimum 15℃ or below, notes Ken. “Farmers should be looking out for hotspots, which will help to identify where insects might thrive. Pitfall traps placed at regular intervals on the surface of the grain and regular manual sieving of the grain should be carried out to see what’s there. Checking and monitoring is crucial at this stage, allowing you to act, if necessary,” he concludes.

More information about K-Obiol can be found here: https://www.environmentalscience.bayer.co.uk/pest-management/products/k-obiol-ulv6