Running through a simple application checklist ahead of key T1 and T2 disease control programmes can deliver sizeable improvements in product performance and yield.

That is the advice from Agrovista technical manager Mark Hemmant, who says as well as providing a better return on investment, keeping on top of disease will minimise the need for curative activity, reducing selection for pathogen resistance and helping to maintain the efficacy of today’s limited fungicide armoury.

“Agrovista has carried out many trials over several years at the important T1 and T2 timings where yellow rust was the main pathogen,” he notes. “These trials clearly demonstrate the importance of correct application techniques. By following a few simple guidelines, growers can significantly improve control for very little outlay and effort.”

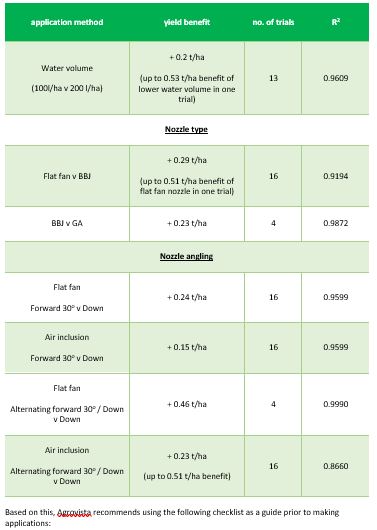

This table summarises the impact of various application factors on yield – in T1 or T2 trials where yellow rust was the main pathogen.

- Boom height – the optimum boom height is 0.5m above the crop. Doubling it typically increases drift by a factor of 10 with flat fan nozzles.

- Water volume – Using a water volume of 100 l/ha delivered better disease control in wheat than 200 l/ha, according to results from 13 Agrovista trials.

- Nozzle type – Standard 110° flat fan nozzles (F110-03) are the best option when applying fungicides to wheat, delivering an effective droplet spectrum that ensures good coverage and penetration at 100-200 l/ha.

- Nozzle angling – Alternating forward-facing (30°) and vertical nozzles along the boom improves spray performance, aiding coverage and penetration.

- Applications aids

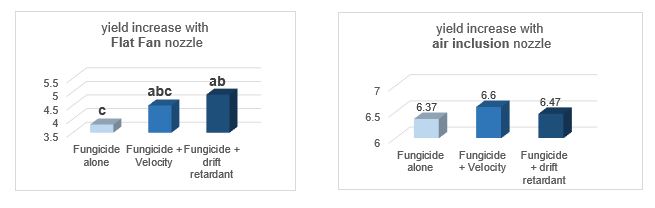

Looking more in depth at application aids, Agrovista has investigated their usage to provide practical solutions, with the results shown in the graphs below, explains Mark.

“In these two separate replicated trials we created some drift by applying the products at the incorrect boom height,” he explains. “We found that the drift retardant significantly improved the performance of the flat fan nozzle where drift was an issue. What’s more, the inclusion of adjuvant, Velocity, improved performance in both cases and was the best option with the air inclusion nozzles.

“That said, it’s also important to check product labels – some products may require use of drift reducing technology when spraying within 30m of water.”

Some might look at this trial and say that the above increase from Velocity is not statistically significant. However, analysis of multiple trial results a consistent benefit – the closer the R2 number is to 1 the better the fit – he explains.

“We’ve clearly proven that adding Velocity to the tank-mix delivers better product performance with any nozzle, improving droplet structure to aid penetration and spread on the leaf,” explains Mark.

“Velocity is particularly beneficial when using air inclusion nozzles, taking performance to levels near those achieved by flat fans. This enables growers to get the job done without having to sacrifice efficacy and yield from using a ‘poorer’ air inclusion nozzle.

“However, it must be said that flat fan nozzles aren’t appropriate for all cases. In fact, air inclusions may allow growers to better time products or help protect sensitive features such as neighboring, field margins or in-field features.”

For more information on the Discovery range – click here

Nozzle selection starts here – click here