A trial on sugar beet in Norfolk is investigating the benefits of strip tillage combined with cover cropping to see if establishment and yields can be improved. CPM assesses the results so far.

It might be that on these heavier soils cover crops don’t have a place.

By Rob Jones

A five-year average adjusted sugar beet yield of 84t/ha is pretty good going by most standards, and it suggests there’s little to fix in the way the crop is grown on the loamy sands at Morley Farms, near Wymondham. Yet farm manager David Jones is always looking to improve his agronomy in the quest to push yields and returns to new levels.

On the farm, sugar beet usually follows winter wheat and all the land is ploughed through the autumn and winter, before being knocked down and sown, preferably by the end of March. Usually this system works well, though in wet seasons such as this or when very dry as it was in 2017, this can compromise establishment.

David has already witnessed the valuable role cover crops can play within the rotation on the 800ha of land he manages for the Morley Agricultural Foundation (TMAF), which includes wheat, malting barley, oilseed rape, dried peas and sugar beet.

A cover crop mix of black oats and vetch (Chlorofiltre 25) was the most successful in the Morley Farms trial.Ploughed-down black oats and vetch, supplied by Agrovista as Chlorofiltre 25, have benefited following crops of sugar beet, in particular, thanks to their soil-conditioning properties.

This set David wondering whether cover crops could be used with reduced tillage to establish sugar beet as reliably as with the plough-based regime. Several years ago, he had tried strip-tilling sugar beet at Morley Farms, but soil structure and establishment suffered in the cultivated strip.

“Strip-tilling uses less energy and is potentially better for the environment and soil, but that needs to be balanced with the ability to grow a reliable, profitable crop,” he says.

“I wanted to see if cover crops could help condition the soil to provide a more reliable outcome from strip-tillage. Machinery has developed and improved since we trialled the method several years ago, and cover crop agronomy has moved on, so I decided it was time to take a further look.”

Given his close association with Agrovista, including several collaborative projects, he asked the company’s technical manager Mark Hemmant if he would be willing to help set up and manage the trials. “The answer was yes, so we set up a collaborative trial between TMAF and Agrovista in summer 2015,” he says.

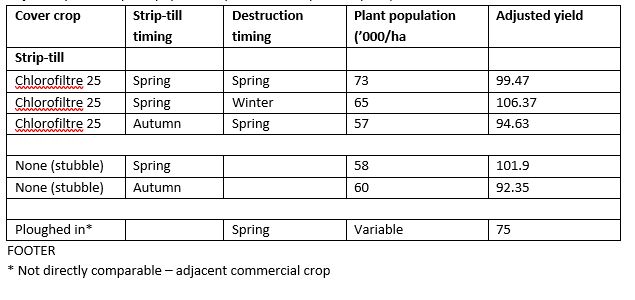

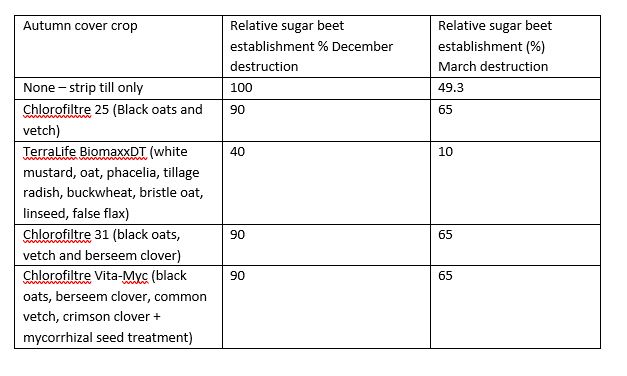

In its first year, four cover crop mixtures (see panel) were drilled in late Aug 2015, while an area of stubble was left for comparison. They were destroyed with glyphosate plus adjuvant Companion Gold (ammonium sulphate + polyacrylamide) at two dates to test the effect of residues, in early Dec and early March 2016.

On 22 April 2016, the large-scale plots were strip-tilled to 20cm using a Cultivating Solutions RLS 600 supplied by Randell Agriculture. The cultivated bands were 10cm wide, leaving 40cm of undisturbed soil in between.

The field was left to haze over before precision drilling with a Väderstad Tempo drill, also from Randell Agriculture, at 1.15 units/ha.

Plant counts were poor following the TerraLife mix and there was little difference between Chlorofiltre mixtures (see panel). As a result, only the Chlorofiltre 25 plots were assessed for yield, along with the stubble plots and an adjacent field where the same cover crop had been ploughed in. Weighing and quality analyses were carried out by the British Beet Research Organisation at its tarehouse.

“The results were encouraging,” says David. “The plot grown after winter-destroyed Chorofiltre 25 yielded more than nearby fields that had suffered most in a wet June. However, it didn’t quite match the yield of the adjacent commercial crop.”

Early destruction of the cover crop did give more consistent results, says Mark. “We didn’t see any significant difference in the yield of strip-tilled sugar beet with or without cover crops.

“But, with careful planning and execution, there were no negative effects from the techniques used and very respectable crop yields were achieved.”

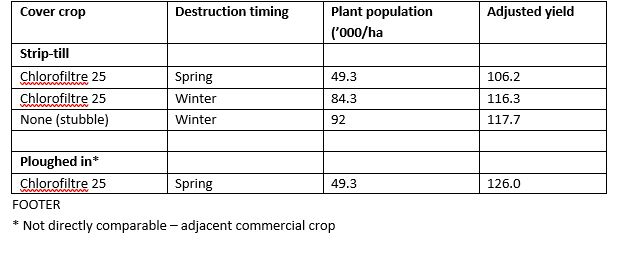

In the second year of the trials, autumn strip-tilling was added to the protocol to see if the drier soils at that time would improve tilth production. Only the Chlorofiltre 25 mix was used, and a split-dose glyphosate (winter and spring) was introduced on the early-destruct plots to ensure complete kill.

Beet was sown on 30 March 2017 at 1.25 units/ha. The plots, on slightly heavier soil than the previous year, suffered patchy emergence in the dry spring, as did the farm’s commercial crops. Perfect growing conditions in the summer helped the crop make up for the poor start, which was reflected in the final yields (see panel).

The crop was harvested on 22 Jan 2018. Again, there was no significant difference between the strip-tilled/early-destruct Chlorofiltre crop and strip-till only. “Yields of both appeared better than the commercial crops, even allowing for the fact that the trials were hand-harvested,” says Mark.

The autumn strip-tilling appeared to adversely affect soil structure and did not work as well as expected.

“We’ve changed the strip-till machine for this third year of trials,” says David. “Processes are always evolving and we think the new Carré machine will improve establishment when used in the autumn and spring.”

After two years’ work, it’s difficult to draw a firm conclusion from the trials, says Mark. “We know from other independent trials that strip-till and cover cropping can have benefits, especially on light soils. It might be that on these heavier soils cover crops don’t have a place, although results look more promising, particularly in year two, with early destruction. We shall keep looking.”

Although retaining an open mind with a third year of the trial still to go, David suspects strip-tilling beet may be best suited to growers who are already using the technique in other crops, or who have ready access to one.

“I don’t doubt that there will be cost savings using the techniques we’ve trialled, and potential environmental benefits that may or may not attract payments in the future, but I couldn’t justify buying a specialist machine at the moment.

“At Morley we host a lot of trials, which necessitates rotational ploughing, so we have not gone down the min-till route with sugar beet. But for growers that operate low-disturbance cultivation systems, it could offer a way to grow the crop, while maintaining the benefits throughout the rotation.

“It’ll take a number of years to refine a different system, but after just two years we’re confident enough to scale up the trials from 3.5ha to 11ha this year, knowing we won’t lose out on yield. We can only learn by trying new things.”

Morley Farms strip-till results

Year 1 trial results

Adjusted yield and plant population (hand-lifted replicated plots)

Establishment in Year 1

Year 2 trial results

Adjusted yield and plant population (hand-lifted replicated plots)