Amazone has always been at the forefront of drilling technology; with the combination of a cultivator and drill in the 1960s, the introduction of tramlining to farmers and then the adoption of targeted consolidation to the seed row for improved germination and seedling development. Their experience in combined drilling of grain and fertiliser goes back to the 1970s with its use in direct-drilling systems.

Drills that deliver fertiliser into the rooting zone are back in vogue as growers aim to optimise establishment and target nutrition. CPM assesses how to get the best results from the technology now available.

Applying a small amount of key nutrients within easy reach of young roots effectively gives the seed its own individual growbag.

By Tom Allen-Stevens

Getting the most benefit from applied fertiliser has always been a key objective for any grower. But the regulatory imperative to do so has perhaps never been greater.

One route to ensure this is to target inputs more precisely to the crop, and there’s clear trials-based evidence of agronomic benefits where this is carried out at establishment, according to Agrovista technical manager Chris Martin. The same drilling technology has benefits for those establishing cover and companion crops, he points out.

The kit used to achieve this has also come on in leaps and bounds, and there are now a number of choices, depending on growers’ individual situation and priorities. Amazone technical specialist Bernd Lummer offers an insight into what these are.

What is seed and feed?

The principle of crop nutrition relies on making nutrients available to the crop at the point it requires them. Applying fertiliser complements the exchange of nutrients that occurs naturally between those held by soil reserves and available in the soil solution.

A seedling’s limited root system can draw these only from the small zone into which it’s placed or from seed reserves. In the case of oilseed rape, for example, the seed supplies enough for just the first 5-6 days of the plant’s life, which isn’t enough to ensure a decent tap root – vital for good crop establishment.

So applying a small amount of key nutrients within easy reach of these young roots can bring significant benefits – it effectively gives the seed its own individual growbag.

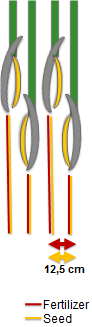

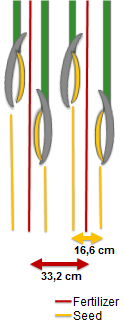

A single-shoot system (left) places the seed and fertiliser together through the same coulter, while a double-shoot set-up separates the two.

Why apply fertiliser with seed?

Phosphate is a key nutrient during establishment, helping a plant develop its root system and it’s needed for photosynthesis. But it’s very immobile in the soil, so a small amount applied in the root zone at establishment gives the plant a valuable boost.

Likewise nitrogen may not be readily available from soil reserves at drilling, especially in no-till situations, as a degree of soil disturbance is usually required to mineralise the N. Mineralisation hits a low point in cold and wet soils, and this makes N fertiliser applied at drilling particularly beneficial to spring crops.

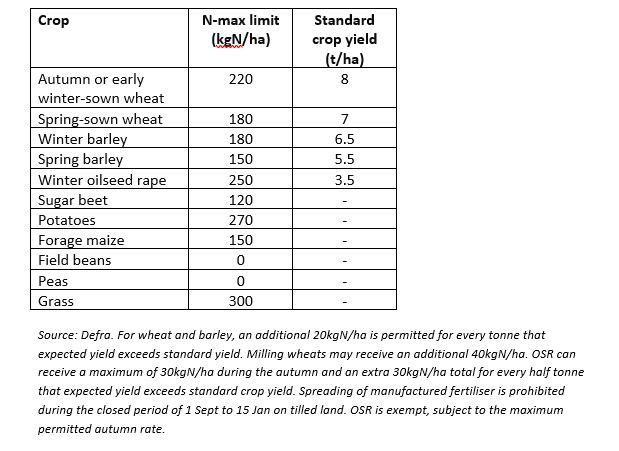

Applying these nutrients at drilling not only makes them readily available to the young seedlings, it also allows them to be targeted. On average, only a third of the field is treated, so the rate can be cut accordingly, or the application can be

more concentrated while staying within N-max limits. So there are both cost and environmental benefits.

What trials evidence is there?

Agrovista has carried out numerous trials on applying fertiliser with seed at drilling through Project Lamport, looking specifically at spring crops, and the National GrowCrop Gold trials, which have focused on OSR. In every year autumn N has been applied to OSR at establishment, this has resulted in a yield benefit that has ranged from 0.2-1t/ha.

For spring cropping, trials have shown the practice to be a no-brainer. Typically 50% of the total N requirement for spring barley should be applied in the seedbed, and spring wheat has a similar requirement. Where soils are cold and wet, the most immediate requirement is phosphate, making diammonium phosphate (DAP) an ideal fertiliser to put down the spout at drilling. An applied rate of 160kg/ha would deliver 30kgN/ha and about 80kg/ha of P₂O₅. By placing the fertiliser closer to the seed, this rate can be significantly reduced which saves money, while also minimising any potential environmental issues associated with N and P.

What are the environmental and crop safety considerations?

Growers must adhere to statutory N-max limits and closed periods. Care also needs to be taken to ensure seed is not placed too close to fertiliser as high nutrient concentrations can impact on germination. Small seeds are most at risk, and urea or fertiliser that contains ammonium N tend to cause the most damage.

What about cover and companion crops?

For those who have the capability to apply both seed and fertiliser at drilling, it makes sense to consider how the drill can be set up to achieve best establishment from cover and companion crops.

Typically, more than one seed will be drilled at the same time, and these are often of different sizes. Experience at Agrovista GrowCrop trials has shown certain seeds can settle out, so the ability to use two or more different hoppers has benefits. Generally, the bigger the seed, the deeper it should be placed, so drills with dual coulters offer advantages.

Examples here include vetch, a large seed that should drilled to about 25mm, and berseem clover, which is best established closer to the surface. Together these make an excellent cover crop. Good results have been achieved drilling OSR with a companion crop of buckwheat. But buckwheat seed is large and hexagonal in shape, so can prove problematic if mixed in the same hopper with the small, spherical OSR.

What drill configurations are available?

Seed and fertiliser can be applied in a single-shoot or double-shoot configuration. A single-shoot system places the seed and fertiliser together through the same coulter. A double-shoot set-up separates the two by at least 2cm.

A single-shoot system works best when seed is placed into cold and wet soils in either autumn or spring, making it ideal for direct-drilled or min-tilled situations. Since the fertiliser is delivered together with the seed, emerging roots get direct access to the nutrients, although care should be taken to keep applied rates below a level that may damage the seed.

Typically a double-shoot system places fertiliser into a furrow between each pair of seeding lines. This means all the required fertiliser can be applied through the drill, ensuring better availability than broadcasting on the soil surface, but with less chance of seedling damage.

What about delivery?

A single-shoot system does not require any special coulters. The seed and fertiliser are metered from a split hopper and carried down the same conveying line to the coulter.

With double-shoot, an extra set of coulters is required, which are typically located in front of the seed coulters and will work around 3-5cm deeper. Double-shoot systems are supplied via a separate conveying line, and sometimes a separate tank. This raises the capital cost and draft requirement, but there’s more flexibility and these are ideal for establishing different seed mixtures, such as cover crops. On some systems, both conveying lines pass to a single special coulter that enable spatially separated seed and fertiliser.

Another consideration is fan speed. With combined delivery, where seed and fertiliser pass down the same line in a single-shoot system, the blower fan speed must be increased. With separate application, the air volume must be divided between the two conveying lines.

What’s the latest tech in this area?

The new Amazone Cirrus-CC drill, that made its UK debut at the Cereals Event this year, is one example of a drill that combines the latest in seed-and-feed technology. This has a second conveying line, offering up to four combinations:

- Sowing just one seed variety via RoTeC pro or TwinTeC+ coulters

- Sowing seed and fertiliser (or a second crop) in the same seed furrow via the single-shoot system

- Sowing into two different seed furrows utilising double-shoot mode and the additional FerTeC coulters

- A combination of both single-shoot and double-shoot modes.

If required, a third crop can also be metered and applied via the on-board GreenDrill 501 hopper, which passes seed through a separate conveying line to either baffle plates at the rear of the drill or a second entry point on the coulter.

Calibration and adjustment of the twin metering units is handled by the optional TwinTerminal 3.0, located on the machine, with rotation speeds displayed on the ISOBUS terminal and adjustable from the tractor seat. The three drill hoppers can also be calibrated via the mySeeder App on a smartphone.

N-max limits for growers in Nitrate Vulnerable Zones (NVZ)

Feeding the seed brings notable crop improvements

Greater precision and success in targeting nutrients where they’re needed are what Keith Challen has achieved since investing in a 12m Amazone Citan drill three years ago. It has an 8000-litre tank split three ways with three separate metering rollers. But all grain and fertiliser are channelled down the same conveying line in a single-shoot system.

“That was an attraction of the drill for us,” explains Keith. “We’ve looked at drills that place fertiliser to the side or below the seed. But what we were looking to do was put the fertiliser right next door to the seed to give it that instant hit.”

As manager of Belvoir Farming Company in Lincs, Keith establishes around 1080ha of combinable crops on heavy Fladbury and Denchworth series soils. “We wanted to move to disc coulters that wouldn’t shift too much soil and encourage blackgrass,” he says.

“We also needed a drill that fits with our 12m Controlled Traffic Farming (CTF) system and one that would cover 100-120ha/day so we could pick and choose the right days to drill. A seed-and-feed drill was a key requirement and we wanted a rear harrow that sweeps the soil sideways, rather than raking it vertically. The Amazone Citan 12001-C was the only one that met all our requirements, was reasonably priced and it’s proven itself,” notes Keith.

For oilseed rape, the main requirement is a crop that establishes quickly to stay ahead of cabbage stem flea beetle. “We apply enough MAP or DAP to give it 30kgN/ha, but that’s across the whole field, so the seeding zone gets a rate that’s substantially higher. That also gives the crop 50-80kg/ha of P₂O₅,” he says.

“For spring crops on heavy clay, our biggest problem is cold wet soil at establishment. It’s why we still carry out minimal cultivations, and we’ve found cover crops don’t suit us as we need soils exposed to the wind to help dry out the surface.

“That shot of N at establishment is essential for spring barley – we put on 100kg/ha of MAP, that gives the crop 11kgN/ha and 52kg/ha of P₂O₅.”

The results are now showing in leaf tissue analyses, says Keith. “We used to rely on soil samples but were getting nutrient deficiencies even where indices were OK. So we take leaf tissue samples coming out of dormancy, before the T0 spray timing and pre-T1. It’s clear from these the crops are now getting the nutrients they need with marked improvements in P. We can now tailor our inputs much more closely to crop requirements, which is also achieved at drilling as we sow at a variable rate.”

One surprise result has been putting Polysulphate down the spout when drilling spring beans. This puts potash, magnesium and calcium as well as a good dose of sulphur into the rooting zone. “We tried two tonnes applied at 160kg/ha across some of beans in 2019 and it lifted the yield by 0.4t/ha to 4.8t/ha where it had been applied,” says Keith.

“The drill’s done everything we wanted and more – you drill into stale seedbeds and you can hardly see it’s been through thanks to the minimum disturbance. What’s more, it’s fitted with RoTeC Pro coulters that haven’t blocked once, and that’s a benefit in itself.”

Seed-and-feed drilling: top tips

- Enrich the rooting zone – Put immobile P within easy reach of small seedlings, while N may not be readily available in cold, wet or direct-drilled situations.

- Tailor the technology – Consider whether single-shoot, double-shoot or a combination of both are what you need.

- Flexibility focus for cover crops – Separate hoppers and additional coulters allow good establishment of different-sized seeds.

Sponsor message:

With the current susceptibility to dry weather in the spring, it is becoming increasingly important to ensure there is an adequate root structure to maximise the potential of both spring and winter-drilled crops.

The Single-Shoot system, employed on all trailed drills such as the Cirrus, Cayena and Citan, provides a supply of phosphate within the seed row for improved seedling development as well as having the flexibility of adding some N where permissible, such as alongside winter OSR. The nitrogen being removed by the breaking down of crop residues can be supplemented by the use of MAP or DAP in the seed row.

Higher rates of seedbed fertiliser can then be applied in between via the FerTeC coulter when sowing small seeds in dry areas where there might be an increased chance of scorch. The new CC system gives the grower the best of both worlds with its ability to carry out both Double-Shoot and Single-Shoot simultaneously.