Moves from minimum tillage to direct drilling, sowing into cover crops and low disturbance have driven significant changes in coulter design and how these are configured. CPM reports.

Today’s drills and their coulters are being designed to cope with a range of different conditions.

By Mick Roberts

All drill coulters have to perform the same task – that’s to place seeds at a precise depth, at the right spacing arrangement with good seed-to-soil contact.

Today a multitude of makers take very different routes to achieving those basic aims as well as now looking at ways to drill through high levels of trash and cover crops and with minimum disturbance.

It wasn’t long ago that cultivation practices used to revolve around having to create a seedbed in which a Suffolk coulter could work effectively. But, as the popularity of ploughing has waned and min-till, zero-till and direct drilling have become more established, it’s now the coulters that are having to adapt to meet the challenges presented by the latest thinking on agronomy and soils.

“Today’s drills and their coulters are being designed to cope with a range of different conditions,” says independent soils specialist and engineer Philip Wright. “There’s now much less cultivation and often high levels of trash. Additionally, there can be the need to disturb the soil as little as possible to avoid moving weed seeds into the surface from where they can germinate.

Wetter conditions and cover crops

“Delayed drilling means they must work in wetter conditions and, increasingly, they have to work into cover crops. Spring drilling is now becoming more common, which brings its own challenges. One of the first questions farmers need to ask is whether it’s possible to meet all these demands with a single drill.”

Flexibility, with the versatility to work in this wide range of conditions, is probably now the most important specification. Drilling depth – whether that’s defined as the layer of soil covering the seed or how deep it goes into a slot – is also critical, as is the spatial arrangement along the row, as well as the row or seed band spacing.

Drills now have to cope with imprecise seedbeds and have the ability to follow contours as well as comply with other considerations that raise a number of important questions, adds Philip Wright. “What do you want to achieve? Do you sow in rows, make just a strip for the seed and crop or a more consistent spread over the whole surface? Do you choose a very flexible drill that can adapt to suit all conditions or something that can be tweaked, or an all-out specialist?

The Sky Easy Drill has a rubber Otico packer roller in front of the coulter disc with skim coulter and following steel press wheels that close the slot.

“Very many thoughts are now being driven by blackgrass control, which leads to the coulter design’s influence on soil disturbance. But if this isn’t a concern. you may be looking for a one that does the opposite and provides varying degrees of cultivation.

“Delaying drilling into late Oct often calls for a simpler, lighter drill capable of working in wetter conditions and catchy situations. In this case it’s likely to also be used in the spring – again in damper soils or those drying out from wetter conditions,” he says.

Conversely, in dry periods in both the autumn and spring, it’s important to judge the seedbed according to the moisture – not just drill it and wait and hope for rain. “In the spring the biggest lesson to learn is to be patient – drill when you can. But in both later autumn and spring drilling situations, to do this you need a drill capable of high outputs to make the most of every opportunity.

“High output involves faster speeds, however, which goes hand in hand with disturbance. Often in a negative way,” he warns.

There’s a broad choice of coulters on a massive range of drills, he adds. But these really break down into essentially four main types – single disc, double disc, tine and disc/tine, but with a great many options.

Passive tine-based coulters can often create more disturbance that discs. But there are new, very narrow designs that do work to overcome this.

Väderstad’s 410mm diameter serrated coulter disc runs at an angle of 3° and its working depth.

Discs are very passive and cope well with residues through their inherent cutting action. They do offer lower disturbance than most, but not all, tines. Their capability to cope with wet conditions can be limited and have a tendency to smear the slot. The same generally applies to double discs.

Another important consideration is how the drill covers the seed, either by pressing closed a slot, or with a following harrow. Good seed-to-soil contact also requires consolidation, but this must be adjustable to suit the conditions and moisture.

“The Bettison drill from the 1970s has a ‘triple disc’ using a single disc to cut the slot and then direct drill with a following double-disc coulter. Looking at the one on show

on the ADHB stand at Cereals I wondered what we’ve learned from the drill. Actually we’ve learned a lot since then.

“The first thing that struck me was the relatively small two-wheel drive tractor on the front. What two-wheel drive could pull a modern drill of the same width? The other point was the drill was part of a system and the second, and most crucial element wasn’t on show: a Paraplow,” he says.

Although it was manufactured and sold by Howard, the Paraplow was developed for ICI by a team of agronomists, soil scientists and engineers. Its unique design uses legs, mounted at a 45°angle, to loosen the soil by lifting and helping it to fracture along natural fissures. There’s very little surface disturbance and the operation doesn’t mix the soil below or bring up clods.

Philip Wright wonders whether this soil structuring basic principle is now the missing link in current reduced tillage systems – especially in the early years of adoption, or following a string of wetter harvests. “It was an essential part of the system, with a low draft requirement, which is proven because the mounted machine was operated perfectly adequately by tractors in the 1980s, which were usually two-wheel drive, much lighter and with lower powers than today.”

Technology has moved on since the Paraplow and Bettison drill were essentially some of only tools UK farmers could turn to for direct drilling and reduced cultivation. These advances include not only new designs but also benefit from the latest materials and manufacturing techniques, and a wide range of soil-consolidating and slot-closing options not then fully envisaged.

Heritage of the Moore Unidrill

The Sky Easy Drill may be a fairly new name to some UK farmers, but its heritage stretches back to the original Moore UniDrill. The latest version is a very different machine, incorporating the most modern designs and technology, says James Woolway, managing director of OPICO.

“Although the original concept is more than 40 years old, in the past ten years Sky Agriculture has made significant changes to the coulters. The discs are now made from a new grade of steel, with the outer 75mm hardened against wear, while the inner section is tempered to absorb impacts,” he explains.

These new discs now open the slot running at 3.5° angle to the direction of travel, which is half that of 7° used previously. This creates less soil disturbance and reduces the power requirement. “The reason this couldn’t be achieved before was that the higher angle was needed to ensure disc rotation in loose, tilled soil. These days, better bearings, precision machining and the firmed soil provided by a front pre-press roller have now eliminated the need for the higher disc angle,” he adds.

The new skim coulter, which sits alongside the disc is now tungsten coated. “It simply doesn’t wear now and we expect it to last the life of the machine,” says James Woolway. “The skim is normally set level with the top of the notch on the disc, so it’s slightly shallower than the disc depth, but it can be adjusted to suit conditions. It also helps to clear out the seeding slot, preventing ‘hair pinning’ of straw.”

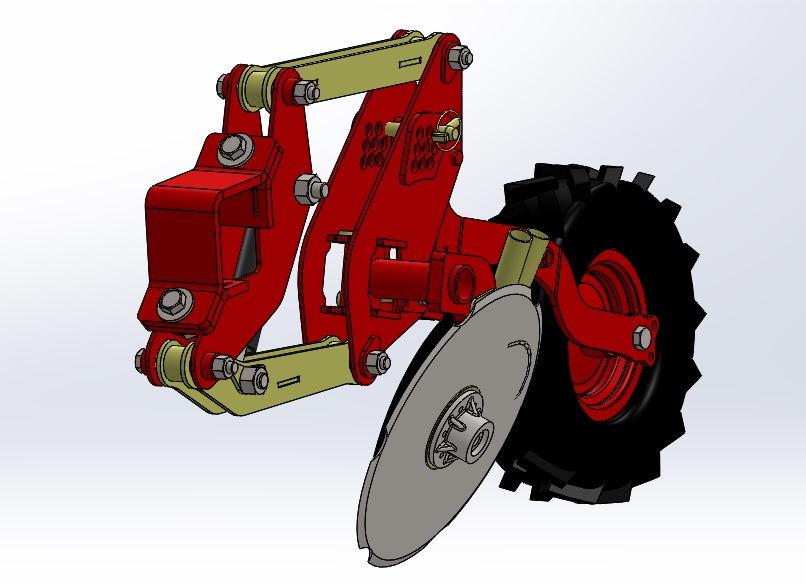

Seeding coulters work in pairs in a ‘seeding line’. At the front a rubber, Otico packer roller consolidates the soil ahead of the coulter discs and sets the seeding depth. The seeding slot is then closed by chamfered edges on the metal press wheels at the back.

Individual disc pressure can be adjusted from zero to 250kg, and weight can be moved to the front or back of the seeding line as conditions dictate. In dry conditions more pressure on the disc coulter and metal, rear press wheels will improve penetration and consolidation, while in wet and softer soils more weight is transferred to the front rubber roller.

Rapid pressure to each disc

The Väderstad Rapid disc drilling principle has hardly changed since its introduction many years ago. Instead of using pressure to push the coulters into the soil the whole weight of the Rapid exerts pressure on each disc. The working depth is set by the rear wheel, which effectively suspends the coulters out of the ground, rather than pressing them in.

The 410mm diameter serrated coulter disc runs at an angle of 3° to forward travel and this cuts the slot into which the seed falls. The delivery coulter runs in the ‘shadow’ of the disc, which effectively clears out the slot before the seed is pressed in by the edges of the tyre packer.

Further disc coulter drilling developments are found on the Weaving GD (Gent Disc) Drill. Developed with Lincs farmer, Tony Gent, it features a new, patented double

disc design, which creates little soil disturbance with a low power requirement of just 40hp/m.

The Weaving GD discs are mounted at a 25° angle off the vertical and pivot around a central kingpin mounted within the coulter body.

The double disc arrangement is mounted at a 25° angle off the vertical and is able to pivot around a central kingpin mounted within the coulter body. The larger, leading outer disc cuts an opening slice in the soil, while the smaller, inner disc is designed to ‘undermine’ the upper side – forming an opening for the seed to be placed precisely.

This, says Weaving, prevents slot side wall compression, providing easier and more consistent closing with firming by the following press wheel, which also acts as a depth regulator. Moving a single pin through a bank of holes adjusts the depth in 16mm steps from 16mm to 144mm.

Kuhn, meanwhile, employs its existing Seedflex, offset double disc coulters on its latest Espro drill. These are now mounted on the new Crossflex seedbar, with suspension provided by four round polyurethane blocks that fit into profiles on the coulter bar within a square tube

The coulters are mounted in pairs on a parallelogram unit, which is equipped with a rear depth-control wheel. A large offset between the double discs opens the furrow, while narrow disc angle reduces soil disturbance, which also helps when closing the slot with the rear press/depth wheel.

Horsch has recently entered the direct disc drill market with its Avatar SD, which has two rows of single disc coulters. These use a straight disc to cut through the surface material ahead of the opener disc that works at a 6° angle, while a rubber-coated gauge wheel controls the seeding depth.

An angled, steel press wheel, running alongside, then consolidates the soil back onto the seeding slot. A more heavy-duty version on the Pronto’s rubber suspension system is used to maintain the set pressure on the coulters.

00 Series opener

Whatever the front tools operators choose to use, with the Great Plains Saxon or Centurion drills, they both use the 00 Series opener. This uses a pair of 4mm thick, 337mm diameter discs set in a V-form, with the inner offset by about 6mm behind the outer to create the seeding slot.

The seeding tube passes between the discs where, just below centre, it splits with the seed trickling down the front half to drop just above the ground. A rear – ‘seed flap’ – is said to stop bounce and maintains depth control.

While Claydon sticks to its original leading tine concept on its drills, it now offers a range of alternatives to the initial A-Hoe share, including narrower points to reduce disturbance and work in wetter conditions.

All start with the patented leading, rigid ‘chisel’ tines, which loosen and aerate the soil and create a channel for drainage and root penetration. This is followed by a sprung seeding tine, which is strong enough to maintain depth through the lifted soil. Following levelling boards and tines cover the seed.

There’s a choice of A shares for seeding in 75mm, 125mm or 175mm bands. Alternatively for lower disturbance the A-share can be replaced by two narrow seeding tines, which place the seed in a 30mm band, which run about 75mm either side of the seeding slot. Seed is placed either side of a single drainage slot created by the leading tine.

Choice of coulters

Amazone offers a choice of coulters on its drills. For example the new 4m folding Cirrus, employs the well proven RoTeC pro system, which it also uses on other drills.

This single 400mm diameter disc is made from 4mm thick Boran steel for longevity and has a special furrow former to reduce soil disturbance. Sowing depth is maintained by a cleaning and depth guidance roller with a 25mm wide contact surface, fitted to the side of the coulter, which Amazone says provides better accuracy than a following roller.

The guidance roller has a high load-carrying capacity, allowing the coulters to operate at pressures up to 55kg as well as travel smoothly through the soil.

Amazone’s Cayena drill is equipped with its narrow, TineTec, coulters designed specifically for low disturbance drilling. The coulters are also already staggered in three rows to provide 16cm spacings, with plenty of room for trash to flow through.

As well as creating minimum disturbance, the narrow carbine-plated points also reduce power consumption, allowing a 6m wide machine to be pulled by a 150hp tractor.

Coulter considerations

* Depth control

* Ability to cope with different seedbeds

* How the slot is closed

* Seed-to-soil contact

* Consolidation

* Soil disturbance

Drill deliberations

* Discs – one or two?

* Seed placement – rows or bands?

* Tines – how much disturbance?

* Discs and tines – how are they combined?

* How does it cope with trash and surface residues?

* How does it cope with undulating ground?

* Is there fertiliser placement and, if so, with, or adjacent to the seed?