Variable rate technology may be delivering benefits, but before taking the next step it’s worth establishing exactly what these are. CPM talks to two growers taking part in on-farm trials to quantify them.

I can’t understand why everyone isn’t using it.

By Tom Allen-Stevens and Rob Jones

For some growers, variable rate applications have brought cost savings or productivity benefits that make the technology a no-brainer. So where do you go from here? Two growers in Agrii’s Digital Technology Farm network are hoping to get a firmer grip on exactly where the benefits lie through on-farm trials that will point the way to further gains.

Pushing zonal boundaries

John Thorne freely admits he’s already convinced about the benefits variable rate applications are making to his farm. “You don’t need to prove the technology to me, in fact I was totally gobsmacked to be asked to take part in the trials – I can’t understand why everyone isn’t using it,” he says.

Flamstone Farms consists of 285ha on the Salisbury Plain, with another 252ha farmed on contract. The nature of the area means John’s average field size is 40ha, but they’re far from uniform – soil type varies from light chalks with clay caps on the hills and ridges to richer, calcareous soils in the valley bottoms, all with a high flint content. Most fields span the complete range.

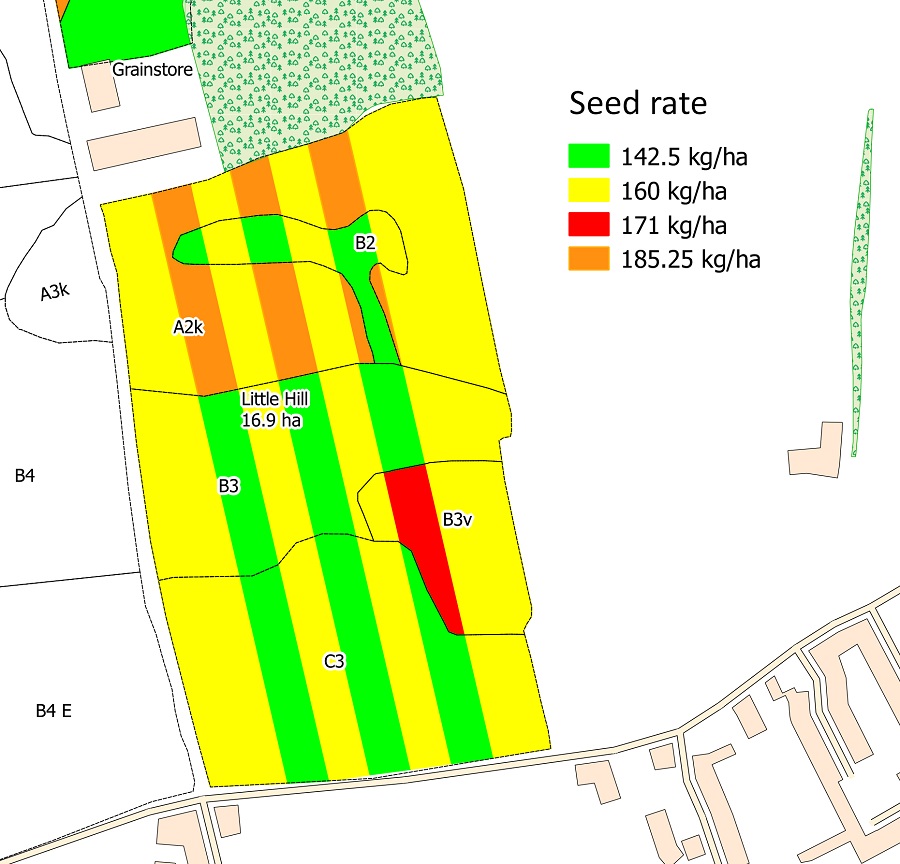

Across three tramlines at Flamstone Farms the seed rate has been varied according to the management zones, with the rest of the 17ha field drilled with a flat rate.

“It was always obvious from the combine cab how much the crop varied,” he recalls. “So we were one of the first farms to map the soils and put them into management zones under the system developed by the Courtyard Partnership, around ten years ago.”

The move was led by Agrii agronomist Peter Gould and the system is now part of Rhiza. “The zones follow the properties of the soil much more closely than the traditional grid method of managing in-field variability – it’s a system ideally suited to these soils prevalent across Wilts, Berks and Hants,” he explains. “John has up to 12 zones in a single field spanning five distinct soil types.”

The zones are set out within Rhiza and Peter varies the intended seed rate according to the soil properties within each zone. “The crop won’t tiller as well on the shallower chalky soil, and establishment isn’t as successful on the clay caps. So in these areas we’ll raise the seed rate, typically by as much as 30% compared with the deeper, calcareous soils.”

The same zones are then used to vary nitrogen inputs. “We know that N is less efficient on the shallow chalks, so the rate is tailored accordingly. We use the satellite imagery provided through Rhiza to do this – one of its useful aspects is a chlorophyll map that shows up as lighter green the chalky areas that haven’t taken up as much N, where rates are raised. Depending on the time of year, the deeper soils may have more available N, so applications can be reined back,” he explains.

“Towards the end of the season we may reverse this, so feed more N to the richer soils where the crop is thicker to ensure there’s enough N to feed the higher anticipated ear count.”

The difference is obvious, says John. “The first thing I noticed is how the crops have evened out across the field. Average yields have also increased to around 11t/ha for wheat – I’ve been amazed at the results.”

The output from Rhiza plugs straight into the Amatron 3 control box that operates John’s 6m Amazone Cayenne drill and Amazone ZA-M 3600 Ultra fertiliser spreader. “It’s very easy to use the Rhiza on-line toolbox to get the latest satellite images and create the application maps. We’ve had no problems with connectivity or compatibility with our equipment. Our main operator, Clover Crosse, who joined us recently, got up to speed in no time – she finds it even easier to use the technology than I do,” says John.

“But it’s essential to have the interpretation from an agronomist. The advantage with Peter is that he knows the system.”

Peter has been recommending the zonal management system available with Rhiza for many years. “Typically growers start by using it to vary P and K inputs and find the savings pay for the work done in setting up the zones in just one year. When varying seed rates and fertiliser, it’s important to ground truth any in-field variation – Rhiza makes this easy because you can bring up maps on your phone and pinpoint where you are in the field.”

He’s keen that Flamstone Farms takes part in the DTF trial because he believes it will give a very clear illustration of the benefits. “I’ve been recommending the system for years, and have seen many farmers benefit, but there’s been very little trials works to quantify this,” he notes.

So across three tramlines in one 17ha field, the seed rate of KWS Zyatt winter wheat has been varied from 142.5kg/ha to 185.25kg/ha. The rest of the field has been drilled with a flat rate of 160kg/ha. “All fertiliser has been applied at a flat rate and other nutrients have been applied according to tissue test results to take out any other variation and ensure it’s purely the effect of varying the seed that we’re monitoring in the trial,” adds Peter.

With three tramlines, it’s a replicated trial, while plant and tiller counts will add to the tissue testing in what he hopes will build into a valuable dataset. Yield data from the combine will be passed through the ADAS Agronomics model which delivers statistical confidence to on-farm trials. “The trial will not only confirm we’re doing the right thing, but should give us a bit more information on exactly how much we increase or decrease the seed rate,” he notes.

John’s confident the trial will confirm the benefits he’s already enjoying. “Greater automation has got to be the way to go to manage my in-field variability. If only this technology could take out weather variability, we’d be sorted.”

Farm Facts

Flamstone Farms, Bishopstone, Nr Salisbury, Wilts

- Soil Type: Light chalk with flint and clay caps to calcareous loam

- Cropped Area: 650ha

- Enterprise Mix: Wheat, spring barley, OSR, peas

- DTF Trials: variable seeding in wheat

- Key trial hopes: “We know there’s a benefit – this is about getting the data to back this up.”

Productivity progress

Precision farming has been at the heart of Martyn Meredith’s improvement efforts at Wood Farm, Almeley in the Welsh borders near Kington for a good 10 years now.

He’s considered conductivity scanning as an essential requirement on all the rented land he has taken on in this time. Variable rate lime, phosphate and potash have also been standard throughout, with variable rate seeding introduced across the 350ha arable business four years ago.

Although satellite imagery provides useful extra support, Martyn, his Agrii agronomist, Graham Jenkins and Rhiza specialist, Ben Burgess find cloud cover and excessive shading in small fields with big hedges limits its value until later in the season. The Rhiza app is, however, proving very useful in marking out drainage plans as well as managing current and historic nutrient maps. And the team sees it becoming increasingly valuable as yield mapping is added to the business’ digital capabilities this season.

“You wouldn’t have the space to chart all the difficulties we’ve encountered over the years with GPS systems, digital boxes and memory sticks,” says Martyn. “At times, it has seemed like a never-ending nightmare.

“Having said that, scanning has been a no-brainer in allowing us to understand new ground as we’ve taken it on, and variable liming and P and K application have enabled us to even up the nutritional status of the mainly clay loam soils nicely. This is very clear in our latest cycle of four-yearly sampling.”

It’s also saved on inputs, he continues. “We were using 12-15t of phosphate and 30t of potash a year but now we’re only needing around 5t and 18t respectively.”

To be fair, the lower phosphate use owes much to the large amounts of organic matter – both chicken muck and FYM – cultivated in every autumn to improve soil fertility and resilience.

Ben points out that potash requirements for the farm in particular, are not insignificant. Feed wheat yields average 11t/ha, with all cereal straw is baled for local sale, OSR pushes 5t/ha and there’s an average of 1m of annual rainfall.

“To be using as little potash as Martyn does on his soils with his rainfall and the yields he’s now getting is a real testament to the way the nutritional status and fertility of the ground has been built up,” he observes.

“So much so that we’ve been able to move away from index-building to a much more cost-effective focus on feeding crops not fields – providing them with fresh available P and K to balance offtakes when they need it, in the seedbed, as a spring top-up and through foliar feeding.”

While variable rate phosphate and potash have become less important to the business over the years as a result, the very opposite is the case with variable rate seeding. In fact, Martyn says it’s been a real game changer.

All crops are now drilled at rates varying by as much as 45%, depending on conditions in general and turning headlands, in particular – of which fields averaging just 6ha in size have more than their fair share.

“Our whole focus with variable seeding is to establish plant populations as near to optimal as possible across our fields so we can bring them to the most productive harvest as cost-effectively as we can,” Martyn explains.

“We always used to struggle to average 10t/ha from our feed wheats. But the past two years have seen us bring in over 11t/ha, and 12t/ha fields are no longer a rarity.

“Like most people, when we started with variable seeding we were increasing rates by 5-10% on the most challenging areas and reducing them by a similar amount on the better parts. But this really only served to move yield potential from one part of the field to another.

“So, now we set our base rate on the day of drilling to what we calculate to be the ideal for the time, conditions, field and variety, then only ever increase it for the challenging areas. Very even plant counts underline how well this has worked – not least in dealing with slug problems.

“On a per ha basis, seed is our least expensive input, so we use it in the best way we can to make the most of more costly fertilisers and sprays,” notes Martyn.

Graham adds there are benefits for nitrogen, PGR and disease-management programmes. “Having the most even plant populations makes managing these inputs so much simpler and more cost-effective.

“It means we don’t have to gear key inputs to the most demanding areas of crop and effectively waste them elsewhere. And we know the inputs will be used with the greatest efficiency across the whole field.”

In Graham’s experience, even crops are invariably the most productive, and they’re also the ones he finds respond best to positive agronomy.

While particularly even plant populations limited the role for variable rate N early on, he finds it very valuable in fine-tuning later applications more closely to yield potential; especially so, using NDVI imagery from Rhiza.

“The even crops we get from variable rate seeding make all the difference when it comes to combining too,” adds Martyn. “Engine loads are exactly the same from one end of the field to the other, which means decent diesel savings and much easier working.”

Farm Facts

Martyn Meredith, Almeley, Herefordshire

- Soil Type: Mainly clay and silty clay loams

- Cropped Area: 350ha

- Enterprise Mix: Winter wheat, oilseed rape, winter oats, spring barley, temporary winter cover for sheep grazing.

- DTF Trials: Variable seeding in winter wheat

- Key trial hopes: “We want to replace feelings with facts and figures so we can really understand where we have the most to gain from the technologies.”

Technology on Trial

CPM is working with Agrii and Rhiza to gain the best possible insight into the pioneering Digital Technology Farm network set-up this spring with growers across the country to scientifically prove and improve key elements of digital agronomy on a field-scale.

Spanning a wide range of soil types as well as rotations and farming systems, the trial and demonstration network has embarked upon a programme of studies employing the ADAS Agronomics precision field data analysis and reporting model to secure the most statistically robust results

This series of articles looks behind the scenes at the digital journeys of the growers involved, the issues they have with current technologies, the future they see for them and what they most want to gain from their innovative initiative.