A robust fungicide approach, based on Adexar, is routinely used to coach Borders grower David Fuller-Shapcott’s wheat into optimum performance. CPM visits to find out how the system and the approach are evaluated.

Yield is king and I do believe in investing in the crop. But it shouldn’t come at any cost.

By Tom Allen-Stevens

It takes a few minutes to find the marker that denotes where the underpants are buried in amongst the grasses and cover of the field margin. The search isn’t made any easier by the rain that’s teeming down near Kelso, just 12 miles from the Scottish border, on a mid-June day when the rest of the UK is experiencing record-high temperatures.

Eventually David Fuller-Shapcott finds the marker and unearths the pants that had been carefully buried eight weeks earlier to gauge the level of biological activity in the soil. “They’re really quite unscathed, and that surprises me,” he notes.

“I thought the activity in the soil on the field edge would be quite significant. But the underpants I buried in the field itself looked far more tattered when I uncovered them, which shows we must be doing something right to the soils here.”

The underpants recovered from the field edge are relatively unscathed, showing there’s surprisingly less biological activity in the field margin than in the crop.

Soil-improvement focus

There’s been a firm focus on improving these Brown Forest and Gley heavy clay soils across the 400ha he farms, based at Sweethope Farm, with the aim of moving eventually to a no-till regime. This has gone hand-in-hand with attention to optimising growth above ground. “It’s about the journey the crop takes from the moment you put the seed in the ground to when you combine it,” explains David Fuller-Shapcott.

“You want it to be as short as possible – not time-short, but in terms of ‘distance’. You don’t want to knock the plant off course, but keep it going on a consistent straight line, letting it make the most of the resources it finds and maximising the light it intercepts.”

David Fuller-Shapcott aims to keep his wheat crop on a consistent straight line, letting it make the most of the resources it finds and light it intercepts.

This is what’s led him to join BASF’s Real Results Circle – a group of 50 growers coming together and sharing results from on-farm trials to find out what really works in the field (see panel below). “Yield is king and I do believe in investing in the crop. But it shouldn’t come at any cost – the investment has to be managed, and you must be sure you’re putting the best regime in place to achieve it,” he says.

The potential rewards are high – this area of Scotland, with its mid-summer daylength and soils noted for their inherent fertility, can push out record-breaking crops. First wheat yields at Sweethope Farm average between 10-12.5t/ha.

A fourth-generation farmer, David Fuller-Shapcott moved with his family to Scotland from Wilts in 1988, shortly after the death of his grandfather. “At the time, the move came as a complete surprise to me, but it meant we could retain the same acreage at a third of the land value. This is man’s land, however, rather than the boy’s land we left behind – manage these soils right and they can achieve double the yields we used to get in Wilts.”

And it’s a delicate balance on soils that don’t forgive a lapse in management, he notes. “There’s a field where ruts were created by pea viners during a very wet harvest, and you could still see these in the crop 10 years later.”

He’s now moved away from the plough, in an area of Scotland that still very much depends on it as the primary cultivation tool. A 3m Weaving Subdisc, combining seven leading tines, a row of discs and a Guttler packer roller, makes a single pass straight after harvest, working to a depth of around 200mm. “We’re aiming to bring the depth up as the soil improves,” he adds.

“We currently drill with a 4m Kuhn power-harrow combination. It’s not kind to the soil, and we’re looking towards a more restricted tillage regime. But we pull this on our slopes with a 150hp Massey Ferguson 6480, which is a relatively low power requirement, so I think we’re heading in the right direction.” Likewise, there’s a relatively small 6m header fronting up the John Deere T560 combine, reducing weight and potential damage to soil at harvest.

Brexit-proof rotation

The rotation is geared towards a regime David Fuller-Shapcott feels is “Brexit and Indy-ref 2-proof”. First wheats follow both oilseed rape and spring oats, with a spring then a winter barley completing the six-year course.

“Second winter wheats don’t pay and the timing is difficult to manage, so we major on the first wheats, while everything’s aimed at soil health and building in resilience. The process revolves around harvesting logistics – wheat after OSR is easy, and so is winter barley after spring barley, although spring oats into winter wheat is a challenge.”

An option under the Scottish Rural Development Programme Agri-Environment and Climate Change Scheme now puts 15ha of this spring oats area into cover crops instead. A mix of black oats, vetch, berseem clover, crimson clover and phacelia follows the overwintered stubble, which is then topped and incorporated in Aug. “This oat-based mix is fantastic for soil conditioning and adds a huge amount of organic matter.”

On headlands around OSR, a radish-based mix, including berseem clover and gold of pleasure, is established. “OSR headlands get pounded and never come to anything, and there are often chemical issues. With a net margin from the stewardship payment of £700/ha, this puts profit into parts of the field that wasn’t there before,” he notes.

With chicken muck applied before winter barley to boost autumn N, and only the wheat straw removed, he’s finding the combination of rotation, cover crops and straw incorporation is bringing more life into the soils.

“Most of it’s down to management and I feel it’s important to recognise what the various crop roots are doing and how they work different parts of the soil. Heavy rainfall can also make these soils unworkable – they won’t let the water through. But get the worm population right and the difference to drainage is remarkable.”

The difference above ground is remarkable, too, notes Catriona Bancroft of Wallace of Kelso – the farm’s agronomist. “With our cold springs, it’s about getting the crop moving early on, and the soil often doesn’t do what you’d expect.”

An N-Min test taken after cover crops gave a very low result, for example. “The aim is not to fix N but to improve soil health and you can tell just by walking over the field this has been achieved – the soil condition is remarkable. This has allowed for investment in the crop and David’s not cutting corners, here. There’s a robust approach and it shows.”

The farm is now part of ADAS’ Yield Enhancement Network (YEN), that closely monitors crop growth and helps growers towards achieving a higher percentage of their crop’s potential. Over the past two years, David Fuller-Shapcott has earned a bronze award with 78% and a silver award with 63.5%.

“The YEN report is fantastic,” he says. “It’s very thought-provoking and does focus you on how you can change things to improve the percentage of potential achieved. We’re doing much more routine tissue and soil-testing, and one thing this has highlighted is that zinc levels could be improved, for example – this can affect ear fertility.”

Bigger job

He also believes fungicides do a bigger job than just disease protection, and Catriona Bancroft reckons this is key to capturing light and turning it into yield. “In this part of the world, crops are slow growing in the spring, but there’s a very long period between the T3 spray timing and harvest meaning we need longer disease protection. Building the crop up so it has optimum performance during that long grain-filling period is the secret to success.”

The BASF Real Results trial is about putting this approach to the test, she says. An essential element of a system that works is to put in the time and effort to evaluate the results. “David’s prepared to turn things on their head and change agronomic practice. He’s pushed the boat out and thought about things in a different way. Our industry is currently starved of good applied research – the best of it’s now happening on farm. So it’s only where farmers put the time and effort into good on-farm trials that you’ll get the progress in crop productivity.”

Trialling a different approach to the Adexar norm

David Fuller-Shapcott has somewhat turned the BASF Real Results challenge on its head for the 13.5ha crop of KWS Barrel under test.

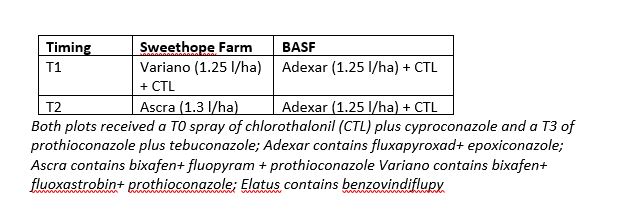

“I work quite closely with the local BASF staff, and already use Adexar across the wheats to optimise their performance. So in the trial, we’ve purposefully set out to find a fungicide programme that we feel will challenge that approach,” he says (see table below).

Sweethope Farm is among 50 farms that have joined the Real Results Circle – an initiative that will allow farmers to conduct their own on-farm trials, backed by BASF.

Seven tramlines have been set out, and these are being monitored and assessed throughout the season by ADAS and AgSpace, who are providing technical support and helping to apply a reasonable degree of scientific rigour to the trials.

The main difference in the programmes under test at Sweethope Farm is the extra strobilurin applied at T1 in the non-BASF approach, points out David Fuller-Shapcott. “The crop did show a little N stress early on during the dry spell, although the fact our soils barely cracked after six weeks of dry weather is testament to their ability to retain moisture. We did apply some amino acid products to destress the plants, however. Now the whole field looks fantastic and you can’t tell the difference between the two regimes.”

Within the 50 Real Results farms are five CPM readers whose progress is being closely monitored, with updates provided throughout the season in subsequent issues of CPM and through www.cpm-magazine.co.uk There are full profiles on the CPM featured farmers, progress reports, Real Results Pioneers features and links to more at www.basfrealresults.co.uk

In Essex, Tom Bradshaw’s Real Results trial sits in a 21ha field of KWS Siskin on Hanslope series chalky boulder clay. Elatus plus epoxiconazole has been pitched at T2 against Librax. “It’s been a pretty simple season for disease control providing spray timings have been right,” he comments. “It’ll be interesting to see how the potential longevity of Elatus performs against Librax in keeping disease at bay, especially brown rust.”

Richard Hinchliffe’s field of Grafton in Yorks is “clean down to the base”, he says. He’s put Ascra across much of the farm at T2, set against Librax in the trial. “Considering the weather this season, I’m not predicting any yield difference ahead of the combine,” he says.

The progress and details of the five demonstration farms and the 50-farmer trial can be followed at www.basfrealresults.co.uk

Sweethope Farm’s Real Results trial

The Real Results Circle

Farming in the UK has never before been confronted with such a perfect storm of uncertainty.

Uncertainty over where the industry is headed post Brexit; uncertainty of returns, because of fluctuating prices and stagnating yields; uncertainty over the removal of chemical active ingredients from the arable toolkit, and uncertainty over which of the mind-boggling array of new products, technologies and tools would be best to try to get to grips with.

To combat growing uncertainty, BASF and CPM are encouraging everyone with a passion for UK farming to unite. We want to help form an agricultural knowledge network of experts, industry specialists, agronomists and farmers.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

This year, BASF’s Real Results Circle is exploring wheat fungicides and oilseed rape profitability. This series of articles in CPM profiles some of the growers who’ve joined the Real Results Circle, giving an insight into how they optimise returns from their crops. We’ll also have topical advice and expert guidance from ADAS on how to get the best from on-farm trials.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk