Small improvements in every aspect of the arable business are helping one S Lincs grower step ahead. CPM visits to find out how on-farm trials are informing the process.

I see my role on the farm as looking to find ways to get that extra 2-3% from every aspect.

By Tom Allen-Stevens

Tim Beaver cups a handful of spring barley from the heap and holds it up for inspection.

“It’s not been a great year for yield, but we’ve a big, bold grain with a low N content. We’ve the best soil type in Europe to produce a malting barley the market wants, and I’m a big believer in growing the right crop for the right soil,” he says.

It hasn’t been a great year for yield on the spring barley, but there’s a big, bold grain with a low N content.

The 550ha he farms, based at Church Farm, Duddington, on the Lincs/Rutland/Northants border, is 40% limestone brash with the rest split roughly half and half medium loams and “man’s land” heavy clay. Barley rotates around winter wheat, grown for nearby Weetabix, oilseed rape and sugar beet. “We grow both winter and spring barley, and it’s the crop we give most priority to, especially on the limestone brash,” says Tim.

Typically it yields 7t/ha and 6t/ha respectively, although both winter and spring crops have been knocked back 1t/ha this year, he admits. But with a good knowledge of the local market and the ability to blend the 1.3% grain N barleys he achieves off the lighter land with up to 1.9% N from heavier soils, he’s confident of securing a good premium. “It’s squeaky-bum time on prices, though, so it’s a case of knowing when to sell.”

As a second-generation tenant on the Burghley Estate, Tim was keen to learn from the experience of barley growing over forty harvests from his father. But he also aims to make his mark across the business. “I see my role on the farm as looking to find ways to get that extra 2-3% from every aspect. So we’re varying the seed rate, tweaking the sugar beet and making the most out of Countryside Stewardship, for example.”

It’s this yearning to seek out the incremental differences that’s brought Tim to BASF’s Real Results, which is already helping to shape how he can wring more from his wheat.

On the barley, the main focus is on nitrogen rates and timings, he says.

“We get the N on early, with the first dose going into the seedbed on the spring barley or as soon as we can travel on the winter crop. Total dose, applied in two splits is 105kgN/ha and 120kgN/ha respectively. We could put on more, but it’s a risk – the grain N has to be diluted, and a dry spell in spring can delay N uptake. If you end up with a barnful of 1.9% N, it’s hopeless.”

Establishment is another key area. “Barley is like sheep – it’ll find any excuse to die, and one thing it hates is compaction.” So taking out wheelings, especially after sugar beet, is a priority, even on lighter land.

“But you’ll only get one day to combine it – miss your opportunity and you can lose the germination. If the ear bends like a McDonalds M, it’s not quite there, but if it hangs, it’s ready. Then you have to watch out for brackling, and we use pea lifters to make sure we pick up as much as we can.”

Variety-wise, Propino has served the spring crop well for many years, while the farm is just moving over from Venture to Craft with the winter barley. “We generally keep a barley for around 3-4 years and farm-save seed, which I reckon helps natural selection – we source the seed from the best of the strongest crop in any year,” Tim explains.

With the wheat, disease susceptibility is more of a driver, he says. “We’re moving away from Britannia, which is a good variety, but not worth the hassle – we were forced into applying a T1.5 spray for yellow rust this year.”

For the Weetabix contract, variety choice and quality spec are less of a concern than they are with barley. “We must be mindful of mycotoxins, which are rarely a problem for us, as we generally apply a T3 spray that’s appropriate to the season. You also have to join Countryside Stewardship or be in ELS. As an all arable-farm, it’s good to have an income source that isn’t dependent on arable inputs. As with anything, the more you put into CS, the more you get out of it. The payment delays are a problem, though.

“What I like about the Weetabix contract is growing a crop with an end market in mind. The growers get together once a year for a look round the factory, and it’s a good opportunity to think about the detail, and how your crop management affects the end product.”

Tim’s taking a similar level of detail into his sugar beet crop, rising to the Beet Yield Challenge, which is prompting him to question how he applies some of the inputs into the crop. But the future of the crop without neonicotinoids concerns him.

“I hope that science will prevail post Brexit – we do need a science-based approach to regulation. I believe there are plenty of opportunities for UK growers if we keep a focus on developing new technologies, such as in drought-resistant crops.

“But I really fear what food and environmental policies will come in. The UK consumer spends the third least in the world on food, which shows that the CAP worked. If the government introduces policies that allow more imports, how do we ensure a level playing field for UK growers? All we’ll do is export our environmental problems.

“These are the bigger questions that are beyond our influence, however. What I can do is focus on in-field trials and other tweaks in the arable system to ensure that, whatever scenario Brexit bowls us, we’ll be well equipped to make the most of it.”

Results pick out where the differences lie

Tim’s always taken a keen interest in “mini experiments” he carries out across the farm. “If you make a miss with the sprayer, for example, it’s interesting to see how yellow rust can take hold. Only by doing in-field comparisons can you know for sure that you’re making your inputs work hard for you,” he says.

“But you can’t just take one result as the gospel – it all adds to the general decision-making. Then there are areas you can improve on in theory, but will these give a resulting yield gain?”

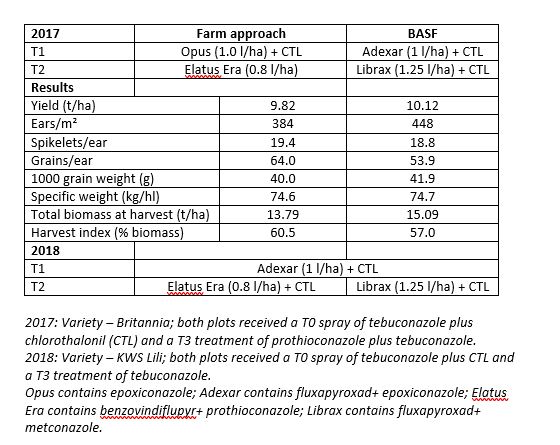

This is the second year he’s been involved with BASF’s Real Results. The fungicide programme on part of a field has been Adexar at the T1 spray timing, followed by Librax at T2, which is played against the standard farm approach. NDVI images, supplied by AgSpace, taken throughout the year build up a picture of how the crop has developed. Harvest results are analysed by ADAS, although Tim didn’t submit his combine yield monitor results, so didn’t yet taken advantage of the detailed Agronōmics analysis in 2017.

“Last year was also our first year with YEN (Yield Enhancement Network) and it’s almost too much information to take on. Now we’ve seen the results, you get a better idea of what to put into it, so you get out the information you most want.”

The BASF programme did perform better last year, yielding 0.29t/ha more than the farm standard. ADAS attributes this to a higher crop biomass, more ears/m² and a higher grain weight.

So what was different? “We went with a cheap and cheerful T1, and I still think that was the right move – disease levels were low and we stayed in a preventative situation throughout the spring. But the BASF area did produce a bigger biomass, and the main difference was the SDHI at T1. There may be something in it, although the YEN report has highlighted 20 other areas to look at.”

Low soil potash and magnesium indices could be holding back potential, he notes. “You also wonder whether some late N, especially on some of the thicker crop, would have pushed it more and resulted in a higher yield. However, while that may have worked last year, this season has been very different.”

Rocky Piece was the field chosen for the 2018 trial. “It’s a bit more brashy, but can give good yields. There are some intersections with Northants red sands and heavier clays, and the winter and early spring conditions would have been a test for the crop.”

Drilled on 10 Oct at 370 seeds/m² with KWS Lili, this time the whole field received Adexar at T1. While neither the NDVI images nor visual inspections showed up any obvious differences, with a new John Deere combine, equipped with a “proper” yield monitor, Tim’s hoping the detailed Agronōmics analysis will highlight any notable variance.

“The field was harvested on 3 Aug and averaged 9.8t/ha at 12% moisture, 72-74kg/hl specific weight and 300+ Hagberg. I’m happy with that, considering we had no rain in June or July.

“Once we get the real results, we’ll have to digest what we have before deciding what lessons can be learned. But with commodity prices where they are, I think it’ll be worth finding a good field, a variety that’ll stand and looking at how much we can push it to perform.”

Church Farm Real Results trials

Innovation tour is a real result

Tim is one of 15 lucky farmers who’s been selected for a tour to uncover some of the secrets of New Zealand’s most productive arable farms. Growers who bought more than 150 litres of Adexar and Librax during the 2018 season were eligible to enter the prize draw to join the trip.

The 14-day tour starts at the end of Nov, with stops on both North and South islands. Highlights include a visit to some of New Zealand’s highest yielding cereal farms and to Crops 2018, hosted by the Foundation for Arable Research (FAR). Growers on the tour will also gain an insight into Revysol, BASF’s new triazole, as NZ growers prepare for commercial roll-out, expected next year.

“It’s a great opportunity, and one I’m really looking forward to,” comments Tim. “It’ll be interesting to see how growers manage without subsidies and explore how both new and old technologies are combined to bring about some of the highest wheat yields in the world – valuable insight that I hope will inform what I do on my farm.”

For full details of the winners, go to www.basfrealresults.co.uk

The Real Results Circle

BASF is partnering with ADAS and AgSpace for the second year of the Real Results Circle. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronōmics tool, which, for the first time, brings statistical confidence to tramline, or field-wide treatment comparisons.

In this series, partnered with CPM, we will follow the journey, thinking and results from farmers involved in the programme. The features will also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk