There’s more to on-farm trials than just putting a fungicide to the test – it can provide a route to query every aspect of an arable enterprise. CPM finds out from a N Lincs grower.

There’s more to on-farm trials than just putting a fungicide to the test – it can provide a route to query every aspect of an arable enterprise. CPM finds out from a N Lincs grower.

I have to be more innovative in my approach and work around what I have – control the controllables.

By Tom Allen-Stevens

Pat Thornton’s put his farm in “special measures”. It’s an approach he’s adopted to address blackgrass that’s seen second wheat ditched from the rotation in favour of a spring wheat that precedes spring barley.

“While we’re getting a grip on the blackgrass, the effect on the bottom line is negative – late drilling and more spring cropping cause overall production to dip, which pushes up cost per tonne. What I focus on is how I can mitigate that lost potential, and that requires every aspect of the arable system to come under scrutiny.”

Pat farms at Low Melwood Farm, Epworth, on the Isle of Axholme – the only part of N Lincs west of the River Trent. There’s 140ha of heavy clay loam, bought by his grandfather after the second world war and shaped mostly by his father into the arable enterprise he runs today. That puts winter oilseed rape and winter wheat into a four-year rotation. Cover crops of spring beans or oats are used in front of the spring crops – another part of the “special measures”.

“There are areas of crop I’ve sprayed off in the past because of blackgrass, and the soil has ended up pretty dead as a result. Cover crops seem to strike a chord – they do bring life to the soil and widen the working window,” he explains.

With costs under scrutiny, however, these crops have got to perform. Widening the working window and spring crops in the rotation allow a small reduction to operational costs, mitigating some of the lost potential.

But Pat’s limited on how far he can reduce his fixed costs. His neighbour carries out his drilling, for example, and he doesn’t have the capacity to transform his system. Yield is therefore king – if he can find ways to eke a little extra from every m² of crop by meeting growth targets and capturing resources, he can improve his yields and restore the farm’s lost potential.

“With a relatively small farm, I can’t afford to be an early adopter. So I have to be more innovative in my approach and work around what I have – control the controllables.”

That’s brought him to Real Results (see panel on pxx). “It’s a new way of looking at things. Rather than run the risk of making a change over the whole farm or enterprise, you put a small area under scrutiny.”

It’s not the first time Pat’s been involved in such a venture. Around ten years ago, as an agronomist with TAG, he led the Fantasy Farming initiative in S Yorks. This was a training programme for TAG members that aimed to add value to, and broaden, core agronomy learning.

It took local supply opportunities, with bakers and millers, for example, and used these as a backdrop. Working in teams, members were allocated a ‘fantasy’ tonne of crop to market and a ‘real’ replicated crop plot. The task was to grow and market the most profitable tonne of crop that met the agreed end user’s requirements.

“The aim was to tailor agronomy toward defined cereal specifications, and included business benchmarking, mechanisation, crop marketing and branding,” explains Pat. “It allowed farmers to try something different in a safe environment.”

That’s also the benefit of Real Results, with the added value that he gets a detailed analysis of how the two different fungicide programmes have worked. “It does make you think about how you influence the various components of yield,” he remarks.

The field chosen for last year’s trial was Calf Close, 20ha of sandy clay loam, drilled with Evolution on 12 October.

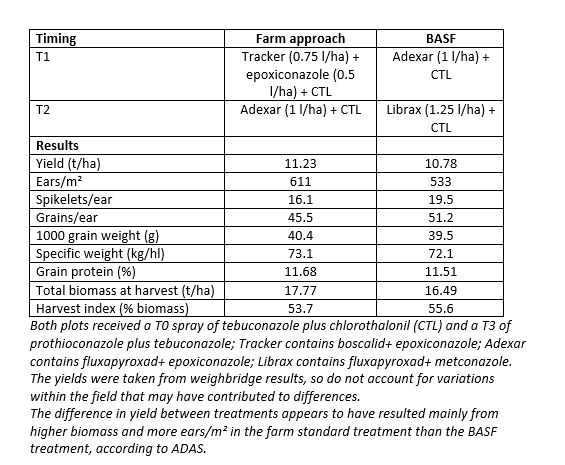

“On the face of it, my standard farm approach yielded 0.45t/ha more than the BASF programme. But within that, there are various aspects where the BASF one performed better. So if you relate those components back to decisions made at corresponding stages in the growing season, it may be possible to combine the best of both.”

According to the AHDB Wheat growth guide, grain yield is the product of three components: ears/m², grains/ear and individual grain weight. Their values are related to the success of different growth phases:

- Ear number reflects growth from the start of tillering to flag leaf appearance (GS39). The AHDB benchmark is 460 ears/m².

- Grain number/ear reflects growth from GS39 to flowering (GS61). The AHDB benchmark is 48 grains/ear

- Individual weight/grain reflects growth after flowering, usually measured as thousand grain weight (TGW). The AHDB benchmark is 50g.

At 611 ears/m², Pat’s ear number is well into the top quartile of YEN growers. Both his farm approach and the BASF programme comfortably outperformed the AHDB benchmark. “My standard farm approach resulted in a far higher number of ears/m² than the BASF programme, and that’s what appeared to have brought the higher yield. I had a focus on stem-based diseases with my T1 spray application and that could have made the difference.”

The BASF programme resulted in more grains and spikelets per ear. Pat’s two results fall either side of the AHDB benchmark and YEN median value of 48 grains/ear. “Once the crop had set its ear numbers, the BASF programme was clearly successful at feeding those ears, and what was there was kept healthy. The question is whether that was down to the Adexar/Librax programme or simply that the lower number of ears in the BASF area meant each ear had more resources to draw on,” he points out.

In a wheat plant, each growth phase will partially compensate for the outcome of earlier phases, according to the Wheat growth guide, so a crop with a sparse shoot density tends to produce more grains/ear and heavier grains than a thick crop.

But Pat’s conscious that poor performance in one phase increases reliance on good growing conditions in later phases, putting the potential yield at greater risk from adverse weather. “In both cases last year, the crop had a robust T2 and set a generous number of grains/m² overall, which seems to suggest that it’s worth investing wisely in the crop right through to flowering.”

There’s very little difference in thousand grain weight and specific weight between the two programmes. “That’s affected by crop health after flowering, so you’d expect that,” notes Pat.

However, the TGW falls way below the AHDB benchmark. This in part is explained by post-flowering weather last year, but specific weight falls below the average 76.7kg/hl, according to the 2017 AHDB Cereal Quality Survey, and sits at a critical value. “Evolution is weak on specific weight and that was further diluted by yield – it limits its use to the feed market”.

So how does that inform how he intends to invest in the 2018 growing season? This year, the Real Results field is a 20ha field on the same sandy clay loam, that was drilled with Dickens on 15 October. By Easter, the crops were still holding back in the cold weather, But Pat isn’t panicking over the T0 spray.

“We’re still in abeyance, but there’s no visible signs of yellow rust. If this inclement weather continues, we may include some tebuconazole with the CTL when we go through with the early growth regulator and trace elements – we’ll decide on the day.”

As for the T1, he’s buoyed by the apparent success of last year’s farm approach. “I don’t think I’ll go too dissimilar – I like the broad spectrum Tracker offers – though it’s worth noting it was cold and dry last April with low disease pressure. Conditions may be different this year,” notes Pat.

One strength he has is the size of his wheat enterprise, however. “The advantage of having a relatively small area to cover is that I can get the application timing spot on – the results suggest that really pays off.”

Nor is he planning much of a change with the flag-leaf spray. “Both of last year’s approaches are good solid chemistry, and the AHDB Fungicide Performance curves suggest there’s nothing between the two BASF products. I may try Elatus Era (benzovindiflupyr+ prothioconazole) as a third option, however.”

But none of his decisions are set in stone – for Pat, Real Results isn’t about which programme performs best. It puts a focus on the aspects of crop growth where decisions matter, and gives him a measure of just how much they count.

“On a small farm like mine, the difference between being in the top quartile of growers and the bottom 25% comes down to the agronomy you apply – you have to make the best decision on the day, based on all the research and knowledge you can glean,” he says.

Low Melwood Farm Real Results trial, 2017

Drilling down through Real Results

The BASF Real results initiative involved field-scale testing on 50 farms, comparing a T1/T2 Adexar/Librax programme with a programme chosen by each grower. Where the farm combine had yield mapping, the ADAS agronōmics methodology allowed statistical analysis of the field-scale results. In the majority of the statistically valid trials, the BASF programme outperformed the competition.

But it also allowed growers to analyse their results, and it’s not just Pat Thornton who’s using these to understand more about his wheat crop.

In Suffolk, Ian Lutey’s Ad/Lib plot outperformed the Adexar/Elatus Era (benzovindiflupyr+ prothioconazole) farm standard by 0.72t/ha. While yield for the field was 11.20t/ha, ADAS puts the difference down to more ears/m² and a higher harvest index. The BASF treatment also had a higher grain protein and specific weight.

Robin Aird, farm manager at Charlton Park Farms near Malmesbury, saw the BASF Ad/Lib sequence out-yield two applications of Variano Xpro (bixafen+ fluoxastrobin+ prothioconazole) at 1.25 l/ha by 0.47t/ha. He was surprised at size of the yield difference, although the BASF-treated crop had looked greener and less stressed. According to ADAS, the yield difference between treatments seems to have resulted from a combination of higher biomass, shoot numbers and grains per ear.

David Fuller-Shapcott, who farms near Kelso in the Scottish Borders, compared Adexar at both T1 and T2 with a sequence of Variano and Ascra Xpro (bixafen+ fluopyram+ prothioconazole). He found the BASF programme yielded 0.8t/ha more. ADAS says the difference between treatments appears to be mainly due to increased thousand grain weight in the BASF treatment, suggesting that programme might have maintained green leaf area for a long grain filling period.

The Real Results Circle

BASF is partnering with ADAS and AgSpace for the second year of the Real Results Circle. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronōmics tool, which, for the first time, brings statistical certainty to tramline, or field-wide treatment comparisons.

In this series, partnered with CPM, we will follow the journey, thinking and results from farmers involved in the programme. The features will also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk