Northants growers Andrew and William Pitts aim to stay two steps ahead of most with the new ideas they bring onto the farm. CPM visits to find out how this objective translates into on-farm trials.

The aim is to discover what’s happening next – that’s far more exciting than what’s happening now.”

By Tom Allen-Stevens

As you follow Andrew Pitts from the field margin to the crop, you’re not sure which holds his greater interest. In one, an array of wild bird cover crops is setting seed, next to knapweed, red campion and lady’s bedstraw drawing a hum of bees. In the wheat crop, the bunched and weighty ears of LG Motown are parted to inspect the structure and life of the Northants chalky boulder clay that lies beneath.

But you sense his fervour actually lies beyond what you see in the field. “We’re growing high quality seed wheat as well as producing record numbers of wild birds and insects – both areas of the farm should make a profit,” he states.

“For me, though, the aim is to discover what’s happening next – that’s far more exciting than what’s happening now.”

William (left) and Andrew Pitts have shaped areas of wild bird cover around the arable cropping and improved and expanded their farmed area.

Two fungicide programmes

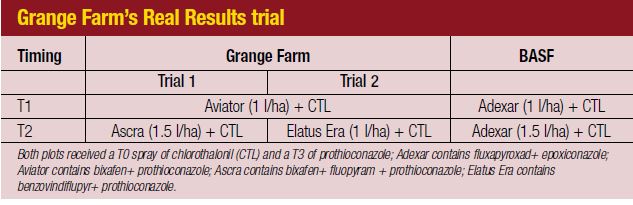

That’s probably why he’s pitched not one but two fungicide programmes against the BASF standard in his on-farm trial. As part of the BASF Real Results Circle, Andrew Pitts is one of 50 growers sharing results from on-farm trials to find out what really works in the field (see below). “You have to keep looking, even if you’re at the top of your game – there’s always another level and a next step to go to,” he says.

Andrew Pitts farms in partnership with his brother, William, based at Grange Farm, Mears Ashby, Northants. The all-arable business has grown over two generations to cover 850ha – some owned and rented with around 150ha contract farmed.

“Dad was a townie with a passion for farming,” explains Andrew Pitts. “He worked his way up from student to cowman to foreman and got his own first dairy tenancy in 1972.”

Both sons joined the business in the 1990s, but it soon became apparent that dairy farming wasn’t stacking up financially. “We had to double the herd or get out, so did the latter. It was the best decision we ever made and meant we could develop the sides of the business we had a real interest in.”

Keen on shooting and the environment, they shaped areas of wild bird cover around the arable cropping and set about improving and expanding their farmed area. “We joined ELS as soon as it started. Then, in 2008, BASF approached us about joining its Sustainable Farm Network. That’s helped us monitor bird counts, improve habitats and develop seed mixes for wild birds that deliver a real benefit.”

He places a chair on the farm-office table to illustrate the approach. “There are four things song birds need, just as a chair needs four legs:

- Habitat to live in all year round

- An insect-rich food source in spring to rear chicks

- A food source during the ‘hungry gap’ from Christmas to Easter

- Targeted predator control in the spring.

“Take one element away, and like a chair it wobbles. Take two away, and your wild bird population collapses.”

Over just four years, the number of breeding bird territories across 100ha of intensively farmed land shot up from 214 to 542, skylark sites rose from 12 to 26, and various environmental awards cemented their success. “But the real victory has been against the single-issue pressure groups who say you can’t have profitable farming and a thriving wildlife in the same place,” notes Andrew Pitts.

With around 500ha of first and second winter wheats, 100ha of spring cereals now open up the rotation, putting four years between the 200ha of oilseed rape. The premium seed market is what 80% of the cereals are grown for, with some varieties grown as early as pre-basic.

“It’s not just about the premium, it gives you a massive competitive advantage – we’re in our fifth year of growing Skyfall, so knew how to get the best out of the variety before most farmers had seen it. There’s a numbered variety we grow that brings us our highest gross margin from the wheats.

“It also challenges you to stay one step ahead, and anticipate what farmers will be growing, and there’s a considerable attention to detail required – the discipline of being a seed grower keeps you at the top of your game.”

Stimulating people

But he wouldn’t call himself a pioneer. “We’re not the first lot of settlers, so don’t get hit by too many arrows, but the next step on. It pushes you to get off the farm in search of new ideas, though, and when you’re with stimulating people, you learn something.”

This describes the farm’s adoption of direct drilling. “We went into Autocasting OSR in the 1990s, against Dad’s better judgement. But it works, as long as the soil structure’s right.” These days, all 200ha of OSR is direct drilled and they plan to establish cover crops off the back of the combine.

Progress into cover crops has been a steady one, and is going hand-in-hand with direct drilling. “We had 40ha that came very late out of spring barley, so left the stubble over winter and established vetches, clover, phacelia and linseed in May.

“By autumn it was a tall cover crop, but we sprayed it off and direct-drilled Skyfall the next day. Establishment was incredibly good with the soil terrific underneath. We found it astonishing, and it opened our minds to something we thought would never work.”

A further 60ha of Irina spring barley were direct drilled into overwintered stubbles earlier this year. Next year, though, the spring barley will follow a cover crop – buckwheat and phacelia sprayed off in Nov to ensure the Hanslope series clays dry out in time for drilling.

It’s part of a plan to ensure the business is Brexit-proof. “We have to find savings of £120-170/ha if the Basic Payment drops out of the picture. Rent may go down, but we can’t reduce establish costs by more than £30-40/ha, unless we take the full opportunity direct drilling offers.”

The plan is to use the period up to 2022 as a transition, aiming to take on more land judiciously as the move to direct drilling eases workload. At the same time, less of each field will be cropped, cutting out the least profitable parts.

“We’ll take out the headlands and the margins of each field and farm the rest of it in the most efficient manner. On uncropped areas we can develop the environmental aspects, provided the incentives are there to give an adequate return – each field will comprise managed controlled traffic farming with birds and bees at the sides and ends,” concludes Andrew Pitts.

Real science applied to farmers’ results

The Real Results field, where the fungicide programmes are being put through their paces, is called Flying Fortress because it’s the site where one of these aircraft ended up after it fell out of the skies during World War II.

Today, the 14ha field is home to an even crop of Motown winter wheat, variable-rate sown at 225 seeds/m² on 28 Sept following OSR. A keen advocate of on-farm trials, the opportunity to get involved with Real Results was something Andrew Pitts was only too keen to take up.

“These will be farmers’ results on farmers’ farms,” he points out. “They’re not plot-scale, so they aren’t farmer-proof and don’t have quite the same scientific integrity. But they’re your own results and have more relevance to you. With modern sprayers and combines, on-farm trials are very easy to carry out, and have great value to others, too, because they’re proper, real-world application of scientific principles.”

He also relishes the competitive element – “it challenges you to change things” – but he’s doubtful as to whether there’ll be a big difference between treatments (see table below). “You’ll see a big difference between good and poor two-spray programmes, but all three programmes we’re trialling are well thought-through four-spray approaches.

“That’s not to say new fungicides can’t deliver the goods – I’ve been fortunate enough to be involved with early trials of Xemium (fluxapyroxad) – the difference you see is like day and night from the rest. But Elatus looks like a good product, and where we used Ascra last year on KWS Santiago, it yielded as well as crop treated with Adexar.

“However, I’m really open to see what happens, and this has turned into a challenging and unusual year. You’d normally expect this field to yield 11-12t/ha, so it’ll be interesting to see how it comes out, and where the differences lie.”

And there’s a fair amount of science that’s being applied to the results, according to Prof Roger Sylvester-Bradley of ADAS, who heads up the team that’ll be analysing the results as they come in.

“We’re using our new, peer-reviewed methodology of applying science to field-scale experimental trials, known as agronōmics,” he explains. This was developed by ADAS with funding from Innovate UK, and is has been accepted as a scientific approach.

“Field-scale trials are not replicated, so you need a way to tell with confidence if any differences are due to the inputs, or simply variances in the field, how it was combined or other factors.

“We apply algorithms to yield data from combine yield monitors to assess this – there’s a high level of replication on the dividing line between two different treatments which is where we focus our analysis. For this exercise, it’s not hugely important what the actual yield is – we’re interested in how the data varies and why.”

With only a handful of sites combined at the time CPM went to press, it was too early to comment on results, he adds. “This level of analysis takes time – we expect to be able to draw some good conclusions towards the end of the year.”

The Real Results Circle

Farming in the UK has never before been confronted with such a perfect storm of uncertainty.

Uncertainty over where the industry is headed post Brexit; uncertainty of returns, because of fluctuating prices and stagnating yields; uncertainty over the removal of chemical active ingredients from the arable toolkit, and uncertainty over which of the mind-boggling array of new products, technologies and tools would be best to try to get to grips with.

To combat growing uncertainty, BASF and CPM are encouraging everyone with a passion for UK farming to unite. We want to help form an agricultural knowledge network of experts, industry specialists, agronomists and farmers.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

This year, BASF’s Real Results Circle is exploring wheat fungicides and oilseed rape profitability. This series of articles in CPM profiles some of the growers who’ve joined the Real Results Circle, giving an insight into how they optimise returns from their crops. We’ll also have topical advice and expert guidance from ADAS on how to get the best from on-farm trials.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk