Understanding is growing about when to use Bridgeway to best effect. CPM digs into the research carried out over the past three seasons and looks at the trends in different crops and seasons.

Experience means nothing if you don’t learn from it.

By Lucy de la Pasture

The subject of biostimulants is one of those that divides opinion. Some growers and agronomists are exploring their potential, others have reservations and are waiting to be convinced. Whichever camp you may fall into, there’s a growing dataset behind Bridgeway that’s beginning to tell its story.

Gaining experience from using the product is shedding light on just where biostimulants usage can pay dividends, believes Stuart Sutherland, technical manager for Interagro. According to the great scientist Albert Einstein, ‘Information is not knowledge. The only source of knowledge is experience. You need experience to gain wisdom.’

“In more recent times the late scientist Dr Chris Green also used to say that experience means nothing if you don’t learn from it,” he comments.

Stuart believes that we’re on the path to knowledge but are still scratching the surface when it comes to really understanding how biostimulants are working, let alone how to get the best out of them. While that may not seem reassuring, it’s a realistic appraisal of the current status quo and a pattern is emerging about where it’s best to target a biostimulant product, he says.

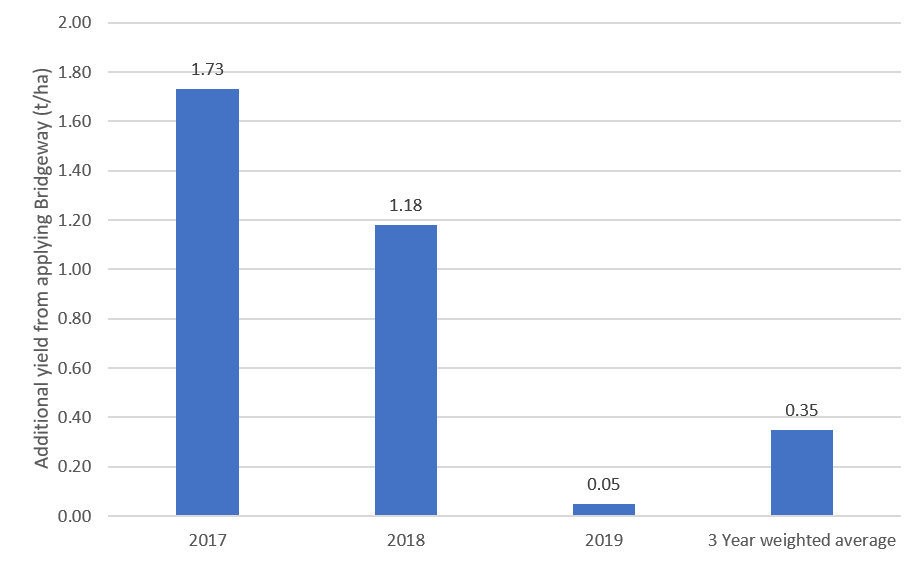

Average yield benefit from applying Bridgeway to winter wheat 2017-2019

Source: Interagro, 2019.

“We have 221 data points from the past three years, so we’re a lot more knowledgeable than we were before. The 2019 season provided a very different growing season to 2017 and 2018 and it’s given us a greater understanding of when to expect payback,” he comments.

The experience to date shows in some seasons, the response to biostimulants has been greater than others, in much the same way as the response to fungicide treatments.

“Investing in a top rate fungicide programme doesn’t always pay back and sometimes you don’t need to if disease pressure is low. The same looks to be true with biostimulants – sometimes they’re not needed so you don’t get the full return on input costs – they’re not a blanket approach,” says Stuart.

His comments come on the back of trials data collected in winter wheat in 2019, which didn’t reflect the large-scale yield responses seen in the two previous seasons. So why was this? In a nutshell, it was down to the weather, he explains.

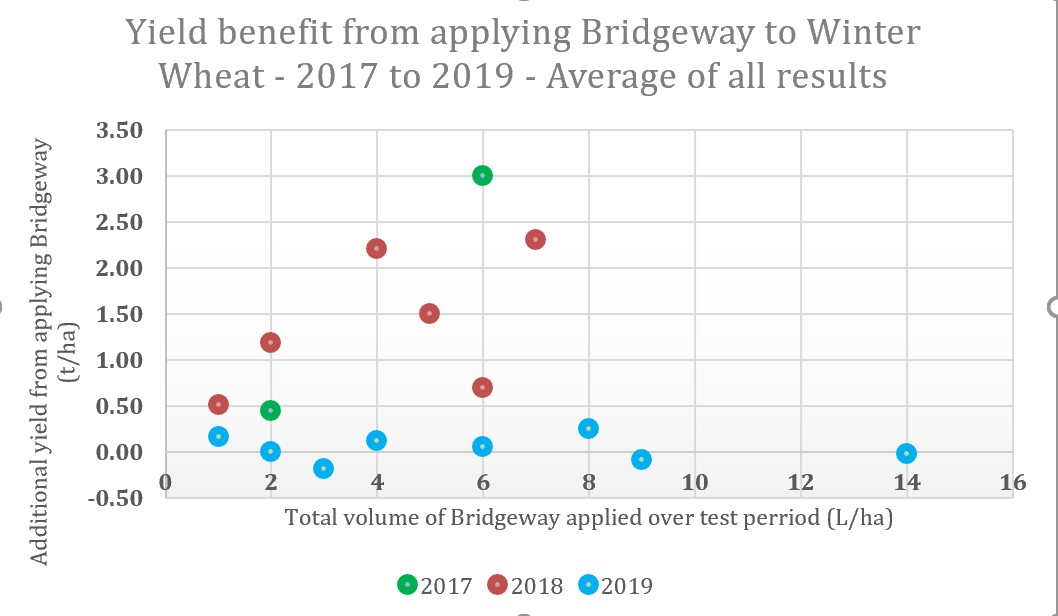

“Looking into the weather data during the core growing months in each season we can see a picture developing. It shows Bridgeway is most beneficial to crops ahead of abiotic stress, such as the heat or drought as experienced during April to June in 2017 and 2018, which put crops under considerable stress (the average yield benefit in cereals was 1.73t/ha in 2017 and 1.17t/ha in 2018).

Yield benefit from applying Bridgeway to winter wheat – 2017-2019

“In contrast 2019 started quite showery, May was warm and sunny with 93% of average rainfall but June was exceptionally wet. Most wheat crops weren’t under stress at the critical growth stages and didn’t show much of a response to biostimulant treatments (average 0.05t/ha),” he explains.

But it was a different story in other crops, with sugar beet in particular showing a positive response to Bridgeway application across the seasons, as underlined in a two-year study carried out by Crop Management Information (CMI), based near Grantham in Lincs.

CMI director, Deborah Green, says there’s a lot of interest in the wealth of new products appearing in the market, loosely classed as biostimulants and biologicals.

“These are receiving a lot of attention in agricultural research in the hope of countering the pressure, in terms of both legislation and biochemistry, on current pesticide usage. One school of thought suggests biostimulants and biologicals may help plants through periods of stress,” she explains.

The aim was to investigate this in sugar beet grown in a commercial situation, explains Deborah. “Application timing to the canopy was modified in an attempt to define optimum stages and sequences for the use of biostimulants. In both years, Bridgeway was the chosen product applied at one or two rates and a range of timings.”

Looking at Bridgeway application in two very different seasons, the results showed a positive trend in both.

“The growing season of 2018 provided an ideal opportunity to study the application of amino acid solutions to a crop that was to become stressed by heat and potential water shortage. The experiment site was drilled into moist conditions after a wet spring, but the month of June proved very hot and below average rainfall. July and August followed in a similar trend,” she explains.

The first three treatment application timings – a single dose of Bridgeway at 2, 4 or 6 true leaves – were applied prior to the onset of a period of excessive heat and drought. There were two further treatments – in the second treatment Bridgeway was applied at 2, 4 and 6 true leaves in sequence.

For the final treatment, Bridgeway was again applied in sequence at the same timings plus an additional three applications at 10-14 day intervals, making a total of six applications. In this treatment the final three applications were made during a period of high temperature and drought in June and July.

There were significant differences between treatments in the weight of beet per hectare at all dig dates. All treatments increased the weight of beet over the untreated, but the biggest significant differences were at the earliest dig date on 28 August 2018, highlights Deborah.

“After this date, the drought broke and the additional moisture from rainfall allowed the untreated plots to ‘catch up’ and so treatment differences were reduced, but there were still significant increases from some treatments,” she comments.

But perhaps of even more interest was the response to different treatment timings, with the biggest effects from the three and six applications. The next best was a single application of the highest rate of Bridgeway (2.0 l/ha) at six true leaves, which was the timing immediately prior to the drought period.

Six applications of Bridgeway made no significant difference to beet yield compared to three treatments applied sequentially at two, four and six true leaves in the 2018 season.

“From the work conducted in 2018, it’d be easy to conclude that applying Bridgeway to sugar beet at six leaves was favourable, and that three applications were better than one, but more applications conferred no further benefit,” says Deborah.

In spite of the significant differences recorded between treatment regimes, visually there was no difference between them in terms of canopy, she adds.

“In 2018 or 2019 visual observations of the canopies were no indicator of what was going on underground. Neither green scans (with a hand-held Crop Circle Scanner) nor dig weights of canopies showed any significant differences at any of the dig dates.

“It was therefore a surprise when such big differences in beet yields manifested themselves in either year. In 2018, these differences could possibly be explained with reference to the hot, drought and the known ‘stress busting’ capabilities of amino-acid applications such as Bridgeway,” she says.

But what was unexpected was the massive response found in 2019, when the summer had been dominated by above average rainfall, so drought stress wasn’t a factor. In both years the same trend in beet yields was found across the treatments tested – six applications conferred no benefit over three, while three were more favourable than one.

“The difference between 2018 and 2019 was that the single application could have been applied at two, four or six leaves to the same effect in 2019, while six leaves was the favourable timing in 2018.”

In an attempt to explain the difference, Deborah highlights that on 22 Oct 2018 untreated yields were 46 t/ha, while on 21 Oct 2019 they were 65 t/ha.

“The two sites were on two different farms, but the difference may also have been affected by the available moisture,” she says.

Sugar content was not significantly affected by treatments in 2018 but an increased beet yield meant an increased gross yield of sugar, she says, adding that figures for 2019 aren’t available yet.

According to Stuart, Bridgeway has been consistently beneficial in sugar beet in all trials to date, but in wheat, experience over the past three seasons indicates the most reliable responses were seen under conditions where the crop comes under stress during the critical growth stages, he concludes.

Good responses in sugar beet

According to Frontier Agriculture agronomist Max Howlett, there’s a bewildering choice of biostimulants products available and it’s a case of sifting through them to find the good ones, with performance potential not necessarily reflected by their price.

“It’s in our best interest to look out for the farmer and find the best products for them to use. There needs to be a margin over input costs to justify using a biostimulant,” he says.

With that in mind, Max has worked with sugar beet growers in Suffolk and looked at a couple of tramline trials in 2019.

“The Interagro trials in sugar beet have shown good yield responses to Bridgeway so we needed to establish whether we were missing a trick.”

One of the tramline trials was conducted over 0.76ha in a commercial crop of sugar beet near Stowmarket and drip fed a reduced rate of Bridgeway (1.25 l/ha) throughout the rapid growth stages of the crop.

“Applications were made on 29 April (five true leaves), 15 May (6-8 true leaves), 4 June (12 true leaves and a final application was made on 18 June. We applied with insecticide applications for virus yellows control, manganese or as a sole application,” he explains.

Asked whether there were any visual differences between the Bridgeway-treated area and the commercial crop, Max says there was none. “We used Soyl biomass imagery to monitor the canopy but didn’t detect any changes, although these would most likely have been taking place underground in the roots.”

Test digs in different areas of the field were carried out just prior to lifting the field towards the end of Sept and revealed that that’s precisely where the Bridgeway was having an effect – on the biomass below ground. Both the yield and sugar content were markedly higher where the biostimulant treatments had been applied when samples were processed by British Sugar.

“The untreated sugar beet had a clean yield of 86.3t/ha (adjusted yield 94.9t/ha) with sugar of 17.5%, whereas the Bridgeway treated yielded 98.3t/ha (adjusted yield 118.3t/ha) with sugar at 18%. That’s a 23.4t/ha increase in adjusted yield,” he comments.

Max believes that the more people begin to experiment with using Bridgeway, the easier it will be to refine a reliable treatment protocol.

“Growers need to be able to see a benefit over the cost of using the product and sugar beet seems to be a stand-out crop in delivering this, with a consistent 0.5% increase in sugar as well as elevated yield,” he comments.

Max highlights that it was only the result of one trial in one season, so Bridgeway still has to prove itself. But he’s seen enough to convince him that it’s worth taking a more extensive look at applying biostimulants to his crops in 2020.

Plans afoot to put Bridgeway to the test

Toby Hogsbjerg manages 1,000ha near Kings Lynn in Norfolk growing winter wheat, winter barley, spring peas, spring barley, sugar beet and potatoes, with some land also rented out for parsnips and onions.

His interest in biostimulants was sparked by the late Chris Green of CMI, who had identified them as a new technology that was worth investigating. The spark was flamed after a lifestyle change prompted him to look after his own health better, , and he changed his philosophy on growing crops as well.

“I believe you have to be open-minded about new technologies and look at more natural ways of growing crops. People are eating our produce, so it makes sense to reduce the dependency on pesticides by increasing plant health, which means crops are better able to thrive without as much intervention and cope with adverse conditions,” he says.

Toby describes the disease pressure in his part of the world as ‘average’ – yellow rust isn’t as much of a problem as it is in The Wash and septoria is less severe than in the West.

“The less agchem we use, the better, so rather than use a routine T0 I’d prefer to look at supporting plant health through nutrition and biostimulant use in the run up to T1 and T2 fungicide applications,” he says.

Toby’s not alone in taking that approach and he’s had a keen eye on other growers’ results, which he says have been variable but promising.

“Most of us believe that it’s the fungicides we apply that are giving us crops that yield, but what they’re doing is stopping the plant from getting the disease. So even though undeniably fungicides help build yield, there are also other ways of improving plant health so that fungicides can be used more appropriately,” he comments.

Last year Toby didn’t have the chance to set up any replicated trials on the farm, but he did use Bridgeway on some winter wheat and spring barley. The field of wheat was drilled after a crop of onions and came out of the winter with yellow stripes marking areas of compaction. Bridgeway was applied as a 2.0 l/ha standalone treatment in March and Toby reports the crop greened up and the biostimulant appeared to help alleviate the stress.

The spring barley crop provided an opportunity to look at splitting the dose of Bridgeway (two x 1.0 l/ha) as well as applying a single dose at the recommended rate of 2.0 l/ha.

“Where Bridgeway was applied there were increases in yield, with the split dose providing a smaller increase than the standalone full dose of Bridgeway. There were differences in fields and varieties so you can’t read too much into the results, but it’s been enough to make me want to take a closer look this season,” he explains.

Moving forward the plan is to put more science into the farm trials to get a more meaningful idea of what biostimulants can bring to the party and Toby intends to look at three different products. He will also carry out split field experiments over the farm to gain even more insight into application rates and number of timings.

“We’ve got to start learning to grow crops without as much chemistry and doing our own research work on the farm is a good way of doing this. But we need to make sure we’re not making recreational applications of biostimulants because it could be good for the crop, they do need to make a difference,” he comments.

Already this season the weather has thwarted Toby’s plan to look at a split application of Bridgeway applied in autumn and spring, but he intends to select trial fields in the New Year with the aim of applying Bridgeway at the end of Jan/beginning of Feb and again a month later.

“We’ve had to abandon min till and we’re ploughing and following with a combination drill so we’re likely to see more soil structure problems and stressed crops than would be the norm,” he says.

From his experience so far Toby believes that this is one of the situations where biostimulants will be most likely to deliver.

Pushing performance

At the heart of good crop production lies careful use of chemistry to protect the plant and maintain performance, right through the season. But optimising the efficacy of plant protection products can be challenging, while increasingly restrictive regulations limit just how far you can go.

This series of articles explores the science behind the use of adjuvant and biostimulant tools to help power both chemistry and crop performance, as well as increase understanding of why they’re needed and what they do. We’re setting out to empower growers and drive crops to reach their full potential.

CPM would like to thank Interagro for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together.

Bridgeway is a foliar biostimulant containing all 18 amino acids essential for plant health. Certified to organic standards, Bridgeway is designed to help plants build resilience to abiotic stress and release yield and quality potential.