For the past few years, Agrovista has been carrying out extensive research into adjuvants to improve pesticide efficacy and has made some remarkable discoveries. CPM takes a look.

Pesticide efficacy is reduced by unsuitable water quality, poor application and inadequate coverage.

By Charlotte Cunningham

Crop protection is a hot topic right now, with arable growers trying to balance efficient usage with protecting available chemistry for the future. At the same time, pressure is mounting from the Government and the public to ensure chemistry is being used as safely and effectively as possible.

So is there a solution? Agrovista believes it’s found one with its Discovery range of adjuvants and tank-mix spray additives. “Often referred to as application aids, adjuvants are a supplement to existing chemistry that improve uptake and distribution of plant protection products,” explains Peter McDonald, head of commercial strategy at Agrovista.

“Pesticide efficacy is reduced by unsuitable water quality, poor application and inadequate coverage, as well as retention on the target surface. But the inclusion of Discovery products as part of the plan helps to overcome these challenges – improving the level of control and increasing yields.”

While scepticism about the use of such products is still widespread, attitudes are changing, and growers are becoming more open to change. On top of this, Agrovista has invested in an extensive amount of research and development. “Each Discovery product has to complete a multi-year pan-European research and development screen to ensure efficacy,” explains Mark Hemmant, technical manager at Agrovista.

“This comprises laboratory studies and high quality replicated field trials across a wide range of geographical locations, soil types, climatic conditions and crops. Physical, chemical, environmental regulatory studies are completed to ensure consistent product performance.”

Time and again these studies have produced some pretty interesting results, particularly in the case of three main products: Companion Gold, Remix and Velocity.

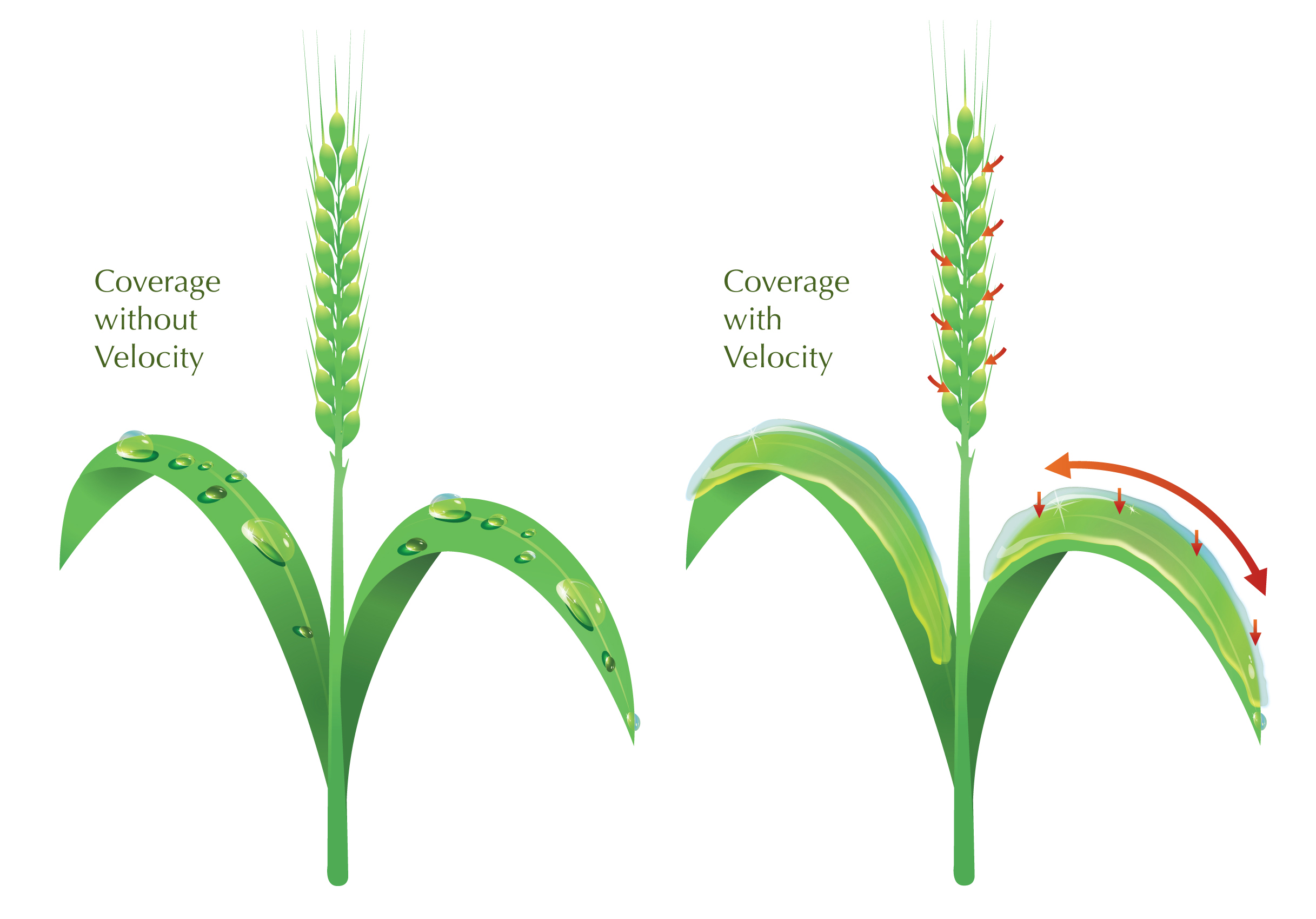

Surfactants in Velocity ensure complete leaf coverage, while fatty acid methyl esters improve penetration through outer wax layers.

Companion Gold

Companion Gold is a multi-functional adjuvant and pod sealant. It provides pH buffering and water conditioning – with differing modes of action for maximum efficacy – together with anti-foam to ease sprayer filling, and surfactants to improve coverage. As well as this, Companion Gold offers spray drift control due to the shear-resistant polymers in its chemistry, and can bring significant improvements in rainfastness.

So what triggered the birth of this product? “One thing we look for as a business is the challenges affecting our customers,” explains Mark Hemmant. “We had noticed drift was an issue in the US, but not yet in the UK, so it was inevitable that this would soon be a problem over here.”

The firm set out in search of a drift adjuvant, and though there was one available on the market, it was difficult to use and didn’t solve the customer problem, he adds.

This led the firm to invest further into the development of Companion Gold. “We put the product to the test with wind tunnel work carried at Silsoe Spray Applications Unit,” notes Mark. “It was put through the same testing as it would with a nozzle to see if it was worthy of a three-star rating and the testing proved Companion Gold did in fact offer the same magnitude of drift control as a three-star nozzle on three-star settings.”

Agrovista also carried out extensive work looking at residue, adds Mark. “We were keen to show Companion Gold wouldn’t increase residue, so we went the extra step, and commissioned residue studies. The results of this led to Companion Gold being on label with glyphosate to use as an adjuvant pre-harvest.”

Other work during the development stage included pod shatter trials, which showed that the inclusion of Companion Gold could reduce pod shatter in oilseed rape, he adds. “We also looked at one or two novel trials. These included drift with fungicides on wheat – with a focus on yellow rust.”

Fast forward to today and Companion Gold is a major player in the market, and with the final usage date of tallow amines fast approaching, this could increase traction further, says Peter. “One of the biggest benefits of the product is that it doesn’t contain tallow amines. With these being withdrawn in glyphosate recently, this has begun a new phase in the life cycle of Companion Gold.”

While tallow amines are still available for use in many water conditioners and adjuvants, this would defeat the point of what the legislation is trying to achieve and may come up against scrutiny in the future, adds Peter. “Companion Gold has never contained tallow amines, and this benefit has come to the fore.”

Going forward, there are grower trials with pod shatter prevention under way, with results expected later this year. “We might also have to look at combining different nozzles with Companion Gold – we’re always looking at the challenges of drift control.”

Remix wraps itself around the herbicide, and the resulting negative charge adheres particles to the soil, keeping the herbicide in the upper layer.

Remix

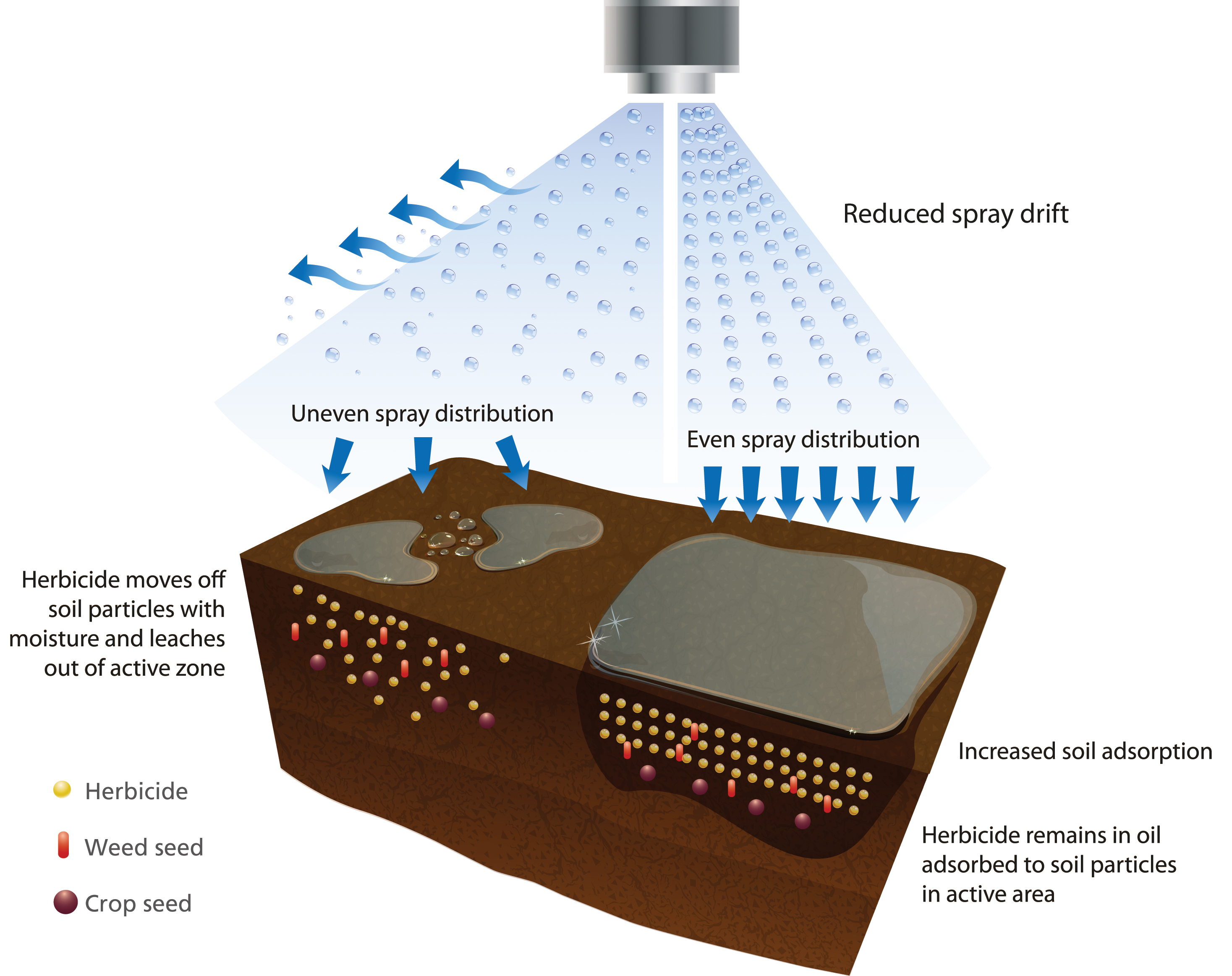

Specifically designed to enhance the performance of residual herbicides, Remix contains aliphatic hydrocarbons, hexahydric alcohol ethoxylates and C18-C20 fatty acids. It’s proven to reduce spray drift, improve deposition on the soil surface and increase adhesion to soil particles – improving the efficacy of pre, or early post-emergence residual herbicides.

“Remix was designed in response to blackgrass – where getting the best performance from residual herbicides is key,” says Mark.

It’s no secret that blackgrass is a huge issue for growers, however, the addition of Remix in a tank-mix with the pre-em herbicide mix can really help to improve control, he says. “Remix wraps itself around the herbicide, giving it a negative charge. This adheres to charge particles on the soil and keeps Remix in the upper layer, from where most weed seeds germinate, and also improves depth protection – so consequently improving both crop safety and weed control.”

The early stages of developments posed two main questions and challenges: Does it work? And if so, at what dose? “Initial trials showed that doses of 0.2 l/ha in the autumn and 0.4 l/ha in spring worked best,” explains Mark.

When LERAPs were first introduced, Agrovista started to get comments from growers that they weren’t experiencing the same level of control from herbicide programmes in their fields that they were seeing in small plot trials, he adds. “This led to a nozzle research, which highlighted clearly which kind of nozzles lead to bigger benefits in performance and the even bigger improvements in control that Remix can bring with farm applications.”

Today, farmers are using Remix to help relieve work load pressure, says Mark. “For example, looking at blackgrass control in the autumn: pre-em applications with Remix help to maintain performance.”

Over the past 10 years, Agrovista’s blackgrass trials have shown that the addition of Remix to a residual herbicide stack has increased control by an average of 11%, compared with using a herbicide alone.

While healthy scepticism surrounds the efficacy of the product, it’s worth having a go, says Mark. “Remix is a leap of faith – farmers need to see the benefits for themselves.”

So what’s next? Continued research into nozzle type, in particular the use in conjunction with twincaps and go low, go slow nozzles, he adds. “Application is at the core of Remix’s future development.”

Velocity

Poor coverage and uptake of fungicides can significantly reduce performance. Designed to tackle this, Velocity contains components that improve spray deposition by reducing drift, and humectants that slow droplet drying – increasing uptake.

Organosilicone surfactants ensure complete coverage, while fatty acid methyl esters improve penetration through outer wax layers.

“When Velocity was first developed, disease control came mainly in the form of triazoles,” explains Mark. “So we knew we needed to develop an adjuvant that improved their uptake and leaf coverage.

“In 2005 prothioconazole was launched, and in 21 trials, Velocity proved beneficial when used with this chemistry. More recently, we’ve carried out research with combinations with strobilurins and then SDHI fungicides – and looked at interactions between pathogens, fungicides and application parameters.”

These trials have shown that water volume, nozzle type, boom height and angling can all have a significant impact on fungicide performance. “On winter wheat, flat fan nozzles at the correct boom height have often outperformed air inclusion nozzles,” explains Mark.

“However, we also know that getting the timing right with fungicides is crucial. So sometimes the use of air-inclusion nozzles, so you can use lower water volumes and raise the workrate, retaining good spray drift characteristics, allows growers to get the job done.

“In application trials over many years we’ve shown that Velocity can bring improvements in disease control and yield with all nozzle types; but in particular with the small air-inclusion nozzle types which are the ones customers like using.”

To put it to the test, Velocity was assessed in 24 trials over seven seasons with a range of triazole + SDHI combinations – with and without strobilurins. Fungicides were applied at GS39, using a water volume of 100 l/ha through air-inclusion nozzles at 14.4km/h, to mimic farm practice. Results showed that adding Velocity increased yields by on average 0.45t/ha across the trials. “Velocity has been around for a long time – so a key part of development has been to make sure it’s beneficial for our customers with new fungicide types as they’ve come along,” adds Mark.

So what are the benefits of incorporating Velocity into a mix? “Velocity improves disease control, and subsequently yields. Better spray application also means nozzles can get the job done.”

Of course, in all development processes, challenges are inevitable. For Agrovista, the biggest challenge was gaining grower confidence. “Like so many of these products, Velocity isn’t a product that is easy to see working,” says Mark. “Have trust in the product and the results will speak for themselves.

“For anyone who’s not yet trialled adjuvants, I encourage them to have a go. They’re not hugely expensive, but the benefits can be huge.”

Understanding adjuvants

Though still widely thought of as ‘muck and mystery’, adjuvants have repeatedly proven in trials to aid the spray application process. Their benefits can be split into four main areas:

Water

Additives can be used during sprayer filling as:

- Anti-foam – these eliminate excessive foaming by physically bursting air bubbles and reducing surface tension.

- pH buffers – high pH in the spray solution and soil water can lead to rapid breakdown (alkaline hydrolysis) of the active ingredient.

- Water conditioners – hard water contains Ca++ and Mg++ cations that react with certain pesticides, reducing efficacy.

Spray applications

Factors such as nozzle type and angle, boom height and forward speed increase the number of driftable fine spray droplets (under 100 microns). Products like Companion Gold contain specialised polymers and Remix has long chain oils that reduce the number of fine spray droplets, ensuring accurate spray deposition on the target.

Foliar effects

Adjuvants like Velocity reduce droplet surface tension, minimising bounce and run off from the leaf surface providing excellent coverage, while also containing humectants that slow droplet drying to increase absorption.

Residual herbicides

Applied pre or early post-emergence, residual herbicides are prone to spray turbulence beneath the boom – resulting in uneven spray deposition over the soil surface.

Using a product such as Remix ensures the soil surface is evenly coated and increases the adhesion to soil particles – retaining the herbicide in the upper soil layer – and improving crop safety, weed control and yield.

Innovation Insight

CPM would like to thank Agrovista for kindly sponsoring this article, and for providing privileged access to staff and material used to help put the article together. For more information, visit www.agrovista.co.uk