Whether using your own kit or bringing in contractors, harvest is the key to success with an AD unit. CPM asks forage-harvesting experts Krone for advice.

By Tom Allen-Stevens

Harvesting any arable crop successfully requires a number of key criteria to fall in line: there’s the condition of the crop, the skill of the operator to set the harvester correctly, and of course the technology and capacity of the machine itself.

With energy crops, what arguably makes harvest that much harder is that you’re probably dealing with an unfamiliar crop, and almost certainly a different harvesting machine. But while the rise of anaerobic digesters may have cast many arable farmers, especially those in eastern counties, into unfamiliar territory, harvesting maize, wholecrop cereals and grass (for dairy cows, for example) is an area in which plenty of expertise exists in other sectors of the industry across the UK.

Krone’s EasyCollect header has two rows of chains to transfer crop, while the XDisc has an auger large enough to cope with a high volume of material.

James Duggleby, of forage harvester specialists Krone, points out the company has amassed considerable experience in this area. AD plants in particular have been part of the arable scene in Germany for the past 20 years, he points out, and Krone has developed machines specifically for this market. So we asked him what the key considerations are to achieve the best diet for the concrete cow.

What machinery works best for forage harvesting?

If you’re growing a forage crop, the only practical way to get it from field to clamp is with a self-propelled forage harvester. Really the questions are what sort of self-propelled unit you need and what capacity to go for. Whether you’re using your own equipment or planning to bring in contractors, an informed idea of your requirements will ensure best results.

So consider what crops you’re planning to pass through the harvester and your harvest window. With maize in particular, you can be faced with shorter days and short periods in late autumn during which field conditions are suitable. Chop quality is also an important consideration with energy crops. Both of these factors will have a direct bearing on the horsepower you require.

What header works best?

It makes sense to consider requirements from the front of the machine to the discharge spout, starting with the header. Your choice here will depend on the crop, and there are some key design details to look for. But for all crops it’s a good idea to choose a wide header and progress through the crop at a slower forward speed – this helps the machine work at optimum efficiency.

The key questions to answer are what sort of self-propelled unit you need and what capacity to go for, reckons James Duggleby.

A maize header should cut the crop and present it uniformly to the feed rollers, stalk first. Krone’s EasyCollect header has knives that work in a scissor action to cut the crop, with two rows of chains to transfer it towards the centre, where it’s turned through 90° and pulled in lengthways. It’s a relatively lightweight design, so while a typical width may be 9m, you can upgrade to a 10.5m header without putting considerable weight on the front.

For wholecrop cereals, such as hybrid rye, the header usually has a reciprocating knife or mower discs, with an auger to pass the crop to the centre. While a reciprocating knife may work well on the dry brittle crop encountered by a combine, mower discs, such as those on Krone’s 6.2m XDisc, are better suited to harvesting green stalks. The auger should also be large enough to cope with the high volume of material you’d expect with hybrid rye, that may be 2.5m tall.

Pick-up headers for mown grass can include cam tracks or guide rollers to help control the grass collection, although the camless design of Krone’s EasyFlow header ensures a faster operation and less maintenance.

What about the intake system?

The job of the feed rollers is to present the chopping drum with a uniform, consistent mat of crop. Bearing in mind there’s up to a 10.5m width of 2.5m tall maize that must compress down to a chopping face just 800mm by 170mm, it’s not a job to be underestimated. So the six feed rollers in Krone’s BiG X forage harvester, for example, apply a pressure of 4.6t to the crop.

As well as compressing the crop, the feed rollers hold it. Think of a chef chopping leeks – you won’t achieve a consistent, fine and uniform chop unless the crop is held firm, so it’s worth ensuring the pre-compression chamber is a reasonably generous length.

Chopping drums come with a different number of blades, depending on the job they’re doing. Generally, the more blades, the finer the chop, which is what you want to aim for with AD, although changing the speed of the crop-intake feed rollers has a similar effect. Krone’s MaxFlow 36-blade drum would be suitable for energy crops, producing a length of chop (LOC) between 3-17mm, dependant on the rate of crop intake. Dedicated Biogas drums with 40 or 48 blades are also available.

Maize, being tougher, requires a knife blade with a thinner profile and harder steel. Soft grass that may have stones in it would soon shatter such metal, so softer-steel blades are better. Wholecrop comes somewhere in between, so the choice of blade will often depend on what else you’re cutting at the time.

It’s crucial to have sharp blades, so the harvester has an active knife sharpener on board. This means a bit of downtime in the field while you sharpen the knives, but doing so little and often – several times a day – is well worth it. A good operator will keep the knives at optimum performance, and a good forage harvester will ensure that’s a quick and easy process.

How is the seed processed?

Important for AD, maize seed and to a certain extent cereals, must be split open. Uncracked seed can cause blockages in the plant, but it’s also a waste of utilisable energy. This is the job of the corn conditioner, that comes in after the drum.

The crop passes through two fluted rollers, with the ribs set horizontally, which travel at different speeds to rip the seed case. But there’s a gap of typically 1-2mm at this point, so the crop experiences massive consolidation and blockages can occur. It’s down to the experience of the operator whether to bring the corn conditioner into play, but a good forage harvester will have enough technology on board to ensure a blockage on a well operated machine is a rare occurrence.

Finally, there’s the accelerator that fires the crop up the spout. Again, consistency of crop is vital, although that can be difficult to achieve, especially in a variable grass crop. Krone’s Varistream helps even out lumps and bumps with spring-loaded floors beneath the chopping drum and behind the accelerator.

There’s also StreamControl, which allows the operator to adjust the aggressiveness of the accelerator. This means the crop can be thrown further – when opening up the field with tractor and trailer following the harvester, for example.

SUBHEAD

Why is chop length important?

This is the key difference between forage for livestock and for the AD plant. With cows, the aim is to maximise milk production, so the forage element in a total mixed ration releases its energy at the right rate to do this. With AD, you’re looking to maximise gas production and expose the maximum surface area of the forage to the bacteria.

Ideally a chop length of 3-5mm will achieve this, but such fine material will behave like water when you’re trying to clamp it, so realistically 8-12mm gives the best of both worlds.

It’s worth being fastidious over chop length – follow the harvester for the first few lengths of the field and regularly inspect the result. A good machine, set up well and well operated, will achieve an LOC in a tight range, with minimal over lengths and well cracked grains. Sets of sieves are available to check a sample – don’t skimp on this aspect as LOC can make a world of difference to the performance of an AD plant.

When’s the crop ripe?

This largely comes down to experience and there’s no rule of thumb. Generally, you’d harvest maize or wholecrop hybrid rye earlier for a digester than for livestock forage – typically for maize achieving a dry matter of 29-34% for AD, compared with 32-38%. In the cob or ear, the grain will be at the cheesy-ripe stage and will show your thumbnail, but will be too hard to squash. The foliage will have gone off green, but won’t be golden.

What about ensiling?

Silage is made in the clamp and the process requires the right bacteria to work in anaerobic conditions. That means mud must be kept out of the clamp, as this introduces the wrong bacteria, and the material must be compressed.

A big and heavy farm loader can do the job, while some use a large tractor, such as a Quadtrac. A blade on a loader is a useful tool for maize, and it’s best to layer the clamp, packing down material as each trailer load is emptied to achieve a uniform compaction.

Contractor favour for the BiG X factor

Contract services to the biogas industry demand the highest possible standards and the ability to offer high work rates, reckons Steve Suggitt of Suggitt Farm Services of Attleborough, Norfolk. That means if you use the most advanced machinery on the market, it gives you a significant business advantage, he argues.

The business harvests 6000ha/yr of feedstock for anaerobic digesters, comprising 400ha of grass, 1400ha of rye and 4250ha of maize, all with a Krone BiG X 770 forage harvester.

“We built our own AD plant in 2011 after 10 years of research and now specialise in supplying feedstock to AD plants, alongside straw baling and muck services, and applying AD digestate,” he explains.

The company’s first Krone forager was purchased after a visit to the factory in Spelle, Germany, which left a highly positive impression on Steve Suggitt.

“The build quality of the feed roller area is better than any other machine on the market – they’re so heavily constructed. Presentation of crop to the drum is also superior and this is reflected in the crop flow and the uniform chop quality,” he says.

Advances in technology made by Krone also help him to keep ahead in an increasingly competitive market.

“The Krone 770 forager has a 36-knife MaxFlow drum, and you notice the increase in performance and chop quality thanks to its redesigned knives – it means a significant increase in crop carrying capacity. More horsepower also gives more torque which handles heavier crops better – there’s more back-up in the engine,” Steve Suggitt points out.

He also likes the adjustable plate (StreamControl) in the discharge chute which allows him to increase or decrease the blow as needed. “You can get right over the top of the tractor and into the trailer when opening up a field.”

With the tight harvest windows imposed on biogas contractors, minimising downtime is crucial and Steve Suggitt is full of praise for the back-up offered by Krone.

“The forager was supplied by Pecks AgriTrac who offer a very good service. But we do a lot of the work on the machines ourselves, and there’s always someone to answer the phone at Krone if we need help – even on a Sunday evening.”

One feature picked out for particular praise is the compressed air system which blows out the feed rollers on a timed circuit.

“It keeps the dust and chaff away from the knives which is paramount for efficient sharpening.”

He comments that the BiG X is very much an owner-driver’s machine offering all the creature comforts needed.

“It’s very easy to operate and seems more refined than other foragers on the market. We work some long hours in the season but the cab is very comfortable, has good suspension, air conditioning and a fridge.”

Control of the header makes for easier working in changeable crop conditions, with variable header speed to match the forager’s forward speed.

“When the going is good, outputs can be up to 60ha/day,” comments Steve Suggitt.

“And in the wet, the Krone is the go-to machine. With big 800 tyres on the front and 750s to the rear, we never get stuck, and the crop processing system is so good that we’ve never blocked a Krone forager up.”

Steve Suggitt has the full suite of Krone headers, and says that the grass pick-up has proved very reliable, while the X-Disc wholecrop unit performs really well, leaving a very even stubble.

“We specified a 12-row maize header to minimise compaction, and it’s a highly productive option,” he adds.

Forage harvesting for AD: top tips

- Select the right machine and set-up. This is based on header width and drum configuration, which will determine the horsepower requirement.

- Ensure the correct chop length. It will be shorter than for livestock forage and it’s worth checking the consistency and making adjustments until it’s right.

- Have the capacity to harvest in the right conditions. For best results, the crop should be at the right stage, while finding a suitable harvest window can be tricky.

- Consider productivity. Ensure that the capacity of all the harvesting machinery can comfortably achieve the required work rates

- Maintenance is key. Keep the blades sharp and the machine well serviced.

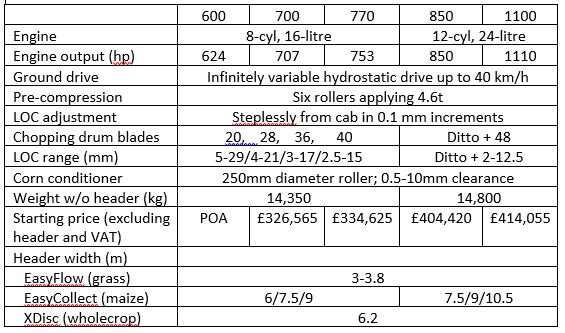

Tech Specs: BiG X Precision-chop forage harvester