With carbon calculators flooding the market of late, Hutchinsons has developed a new tool within its Omnia platform which incorporates multi-layers of data to provide what is claimed to be a highly efficient way of calculating the true cost of carbon on farm. CPM finds out more.

Our view is that managing carbon is not actually about carbon – it’s about managing good business.

By Charlotte Cunningham

Whether it’s minimising its loss or sequestering it, carbon is everywhere you look in agriculture.

It’s clearly understood that improved farm productivity is good for business and for carbon. But the challenge as always been how to measure how much it has cost in terms of carbon to produce a particular crop.

As such, there’s been an undoubtable surge in carbon calculation tools on the market. However, some of these tools have faced criticism, both in terms of their usefulness and validity.

But a new carbon module within Hutchinsons’ Omnia platform – tried and tested on its Helix ‘proofing’ farm – has been designed to tackle just this, providing users with arguably one of the most in-depth tools on the market.

The Production module allows growers to calculate the carbon cost of their operations on a per field basis in terms of both £/t CO2/t or CO2/ha.

“We’re constantly trying to innovate and bring new solutions to market,” explains Matt Ward, services manager. “What’s important to remember here, however, is although we want to be able to give growers more uses for the data they’ve got it has to be in a way that’s still practical for them to do – otherwise uptake will be limited.

“Sometimes the ability to do something isn’t the challenge – making it easy to do so is.”

Matt explains that Hutchinsons has always envisaged a system which provides a total solution to users. “We’ve been able to do a cost of production analysis within Omnia for several years now where it has been possible to identify both the poorest and best performing areas of a field, providing the opportunity to make management decisions based on a sub-field information. Users have then been able to create average cost of production information by crop, market outlet, variety or by field using known or predicted costs, with known or predicted yields -and it struck us that each operation comes with a carbon cost and footprint itself.

“So, what we wanted to be able to do was create a module so when growers were creating a cost of production analysis, they would also simultaneously be able to look at a carbon analysis. This would give both a financial and carbon equivalent position related to a particular crop.

This required a lot of work in the initial stages, explains Matt. “This was mainly deciphering exactly what was involved in every operation. For example, just saying you use minimum tillage to establish crops isn’t going to cut it because you need to know much more about the individual kit, conditions and cropping.

“So we wanted to be able to capture that variation and see how we could utilise that information.”

Within the new Planning module there are two elements – ‘Shed’ and ‘Production’.

Starting with the ‘Shed’, this is where all machinery information is stored. “This area retains information on a variety of kit – from sprayers to combines – so we’ve grouped them all under the ‘power unit’ heading,” explains Matt.

“Most power units are then doing something – they’re pulling or have something behind them – so we then added in an implement section to make sure we were generating a truly accurate carbon picture.”

Walking through the app, Matt explains that this data has to be input manually by users, and requires information like the name of the unit, the year of manufacture and the horsepower. “This is important as there are international standards for the embedded carbon emissions within certain sizes and ages of machinery, explains Matt. “So each power unit has an amount of embedded carbon and by identifying what that is, how big and how old, we’re then able to identify the carbon footprint of that unit.”

Using the example of a cultivation tractor, pulling a cultivator, the embedded carbon emissions of the implement must be taken into consideration too. “This can be done simply by inputting the width of the machine and when it was manufactured,” he adds.

Users can then combine those two elements – the tractor and its implement – and create an ‘operation’ within the module. “If you know the fuel rate in terms of litres/ha then that can be inputted or, if not, we can work with the grower to decipher fuel use and work rate to generate a litres/ha figure. That will then show the carbon cost of that operation.

“That cost is a cost we’ve put in as a default value – but the grower can manipulate this themselves if necessary.”

To add simplicity, growers can then create ‘groups’ within the module – again to minimise input after initial set up. “This means, for example, instead of having to manually input using a carrier, a direct drill and then a roller in each field, users can group this as ‘drilling’ to save time.

“Another example would be group pre-emergence spraying, pre-drilling Roundup (glyphosate), and post-emergence weed control as ‘autumn herbicides.’

“I grant you that this is a lot of work initially – but once it’s done, it’s done. The only time users will need to go back and make amends is when they buy a new piece of equipment.

“And what this initial input does give you is a shed-full of machinery and their associated costs all in one place – both in terms of pounds and pence and carbon emissions.”

The second part of the module is ‘Production’, whereby the machinery and operations can be allocated to specific fields. “This is where the real magic happens, bringing in and layering a wide range of data which growers have already put into Omnia,” explains Matt. “As well as the operation information, we can bring in cropping type, seed rate, fertiliser rates, crop nutrition etc to generate a carbon cost for each field on the farm.

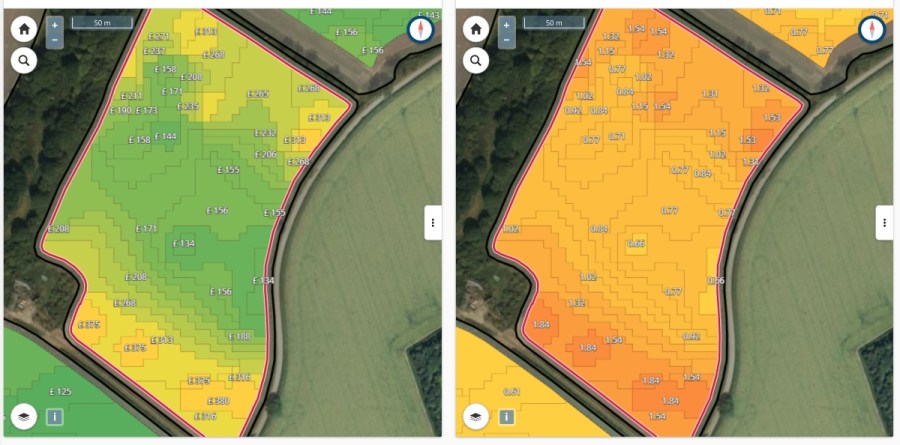

But the detail doesn’t stop there, this carbon cost is able to be split right down to individual parts of the field or sub field level– highlighting the most profitable, and unprofitable, parts of the field. “We also bring in fixed cost information which gives both a financial and a carbon emission cost for every operation.”

Perhaps more importantly, growers can look at tonnes of carbon output per tonne of carbon emissions. “This actually can show a slightly different picture and the software has the capabilities to highlight variable amounts of carbon emissions per tonne of output.”

Demonstrating this on a working farm model, Matt highlights that this can vary between 0.5t of carbon emissions, to five times greater – in the same field.

“Users can split the screen to compare this with other sources of information – cost of production, for example. Unsurprisingly, this model shows that the cost of production is lower where emissions are also lower – making the business case for more efficient carbon farming.

“This is the mantra we’ve been training our teams to understand, which pass on to farmers. Our view is that managing carbon is not actually about carbon – it’s about managing good business. It’s about being more efficient, and growers will get improved carbon output by operating as a more cost-effective business.”

While the firm are the masterminds behind the technology, they don’t claim to be experts in carbon accounting, and have drawn upon the expertise of the Farm Carbon Toolkit. “Becky Willson and her team are experts and were able to provide a much more accurate level of detail than we could alone.

“It was important that we were delivering meaningful, viable information for all of the costings that we allocated to particular operations.”

Becky says partnering with Hutchinsons has allowed the capabilities of the Farm Carbon Toolkit calculator to increase immensely. “What’s been really interesting and exciting for us has been the ability to take the data contained within our carbon calculator – which has been designed for looking at the carbon balance across the whole farm – and break it down into field, and even sub-field, level.

“This will allow users to delve into greater detail than was available before. In terms of what’s possible from a management perspective, this will enable growers to make far more accurate decisions as the impact of field-management on carbon status is so clear.”

The process hasn’t been simple, however, involving a lot of tweaking and modifications to be able to present data in a meaningful, useful way, she adds. “The process involved having to link the emissions and data sets used in the calculator and apply them to individual operations at an at-field level. It’s been difficult, but the figures we’ve been able to generate as a result are much more accurate for those growers really looking to understand carbon emissions on farm.”

As FCT’s carbon calculator has been developed a significant barrier has always been data entry, says Becky. “And effectively, the end result was solely a carbon emissions figure.

“But by incorporating this new module into the Omnia platform, it generates a much greater output and reward from the data entry – with Omnia bringing in all kinds of layers of data – giving a much greater insight into the status of the business, from both a financial and carbon perspective.”

But the work doesn’t stop here for the team at Hutchinsons. They’re already developing the tools to allow users to create and model potential in-field scenarios to measure the likely impact an investment in a specific piece of kit or a change of cropping could have, for example, explains Matt. “This is the second stage of development, which we hope will be available by the end of the year.”

Becky believes that this will be a really useful additional tool for growers. “Everything we talk about at the moment links to longer term management planning, and the modelling capabilities of the module will allow growers to do just that.

“For example, they’ll be able to really dig down into the productive and unproductive parts of a field and if the carbon cost of getting something to grow isn’t worth it, then it flags an opportunity to look at stewardship or other government schemes.

“It’s a really exciting time for carbon accounting – with talk of new subsidy schemes linked to environmental impact, as well as the prospect of being able to offset and trade carbon in the future.

“However, unless you know your status, participation will be limited, so it’s really important to take those first steps. And from a fundamental farming point of view, there’s a really strong relationship between better carbon efficiency and increased profitability too.

“But it’s even bigger than that, and it’s important to look at the role of farmers and food producers within the supply chain. Growers have a fundamental role in being able to address the climate change crisis and make a really difference – I think that’s really exciting.”

An ‘invaluable’ tool

Hutchinsons’ national Helix site in Northamptonshire is hosted by Andrew and William Pitts. It’s here the testing and trialling of new technologies takes place – including the new Omnia Production module.

Andrew has seen the module in action. He says from a practical grower’s point of view, the tool adds another layer of accuracy when it comes to understanding the true costs of crop production – from both a financial and carbon perspective.

“I have to say, when I was shown the module I was completely blown away,” beams Andrew. “It was the same kind of feeling as when you see your first yield map – for the first time it seemed we had a tool available which really could accurately help us to plan our carbon usage.

“It’s ground-breaking without breaking the ground.”

After two very wet winters, Andrew says the decision-making he’s faced this autumn is a prime example of how such a tool could be used. “While our primary cultivation is always direct drilling, this year we’ve got some ground that’s a bit tight, so we’ve had to move the soil.

“Our environmental and carbon footprint is something we’re really prioritising on farm so, in my mind, I’ve had to think about which is the lowest carbon way of moving soil. Is it hiring a Challenger? Or would I have been better to run a low disturbance subsoiler over the ground?

“Now I’ll be able to take the guess work out of it and make educated, informed decisions.”

Andrew believes that it’s becoming increasingly important to be able to show both financial profit and environmental sustainability – and a tool such as this puts him one step ahead in being able to do this. Ultimately the pressure for net zero will continue and Andrew reckons if he can show end market buyers the value of his carbon emissions for a particular crop, then that puts him in a stronger position as a supplier.

“If I can manage carbon emissions which are intrinsically linked to reduced costs of production and better yields then I will have a healthier bank balance.

“What’s more, there’s opportunity to transfer this down the supply chain. For example, with pressure on supermarkets and suppliers to offer more ‘environmentally-friendly’ food, if I can produce ‘carbon-negative’ wheat, then at some point there’s bound to be a premium for this. This is what I believe should be driving an incentive to minimise our emissions – not government funding.

“This is the beauty of the Helix project. A farm is a business and businesses are based around making a profit, and so Helix really examines whether or not technology is going to make my business more profitable. If not, then it’s just another pointless tool on the market – what I’m looking for is to incorporate tools which add value to my business.

“And any tool that allows me to measure, monitor and improve carbon usage is invaluable. If I know what I am producing now, then I can adapt this going forward. I am creating a verifiable ‘line in the sand’ of carbon emissions.”

Digital Direction

As arable farms progress towards a digital future, it can be difficult to know which forms of data generation, capture and analysis provide a really worthwhile benefit to the business, and which are costly and time-wasting distractions. CPM is working with some of the industry’s leading companies in this area to bring growers some Digital Direction. These articles track the significant steps on the journey towards the data-enabled farm, and also explain and profile the technologies involved.

CPM would like to thank Hutchinsons for sponsoring this Digital Direction article and for providing privileged access to staff and material used to help bring it together.