Newhouse Farm has already accomplished significant progress with its carbon savings and sequestration. CPM visits to find there’s a refreshing air of excitement for what lies ahead.

I look at ELMs and I see opportunities.

By Tom Allen-Stevens

What’s remarkable about the 10ha wheat field close to the farm buildings at Newhouse Farm, near Winchester, Hants, is not the area of cropped land but patches within it that aren’t.

“It’s our agroforestry project,” explains farm manager Andy Bason. “We have eight 4m wide strips, 30m apart. The plan is to plant them with wildflowers and apple trees. It’s a bid to capture more carbon in the field and increase beneficials and biodiversity, so reduce reliance on pesticides. I hope that when the apple trees produce fruit it can be part of a community apple-picking project.”

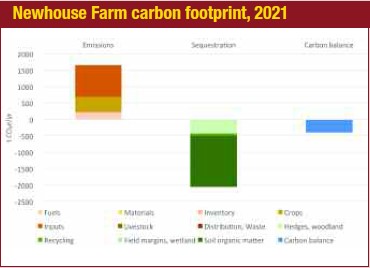

Newhouse Farm is already carbon positive, with soils particularly good for retaining carbon.

The farm is already carbon positive, capturing more into the Hants chalk downland with clay caps than the farm operations release in emissions. Changing tillage practice and years of environmental work, including a mid-tier Countryside Stewardship agreement coming to an end next year, have ensured a confidence and the understanding as to what works.

But Andy has an infectious enthusiasm for his plans to do more, and a thirst for the knowledge he’ll glean on the journey. “These are exciting times in farming for those willing to go with it, and we have particularly good soils for retaining carbon,” he says.

“I look at ELMs and I see opportunities – it’s one of my goals to enhance our environmental credentials and incorporate these into the arable operation. But how can you move forward if you’re not open to new ideas? I like to look outside the box and encourage a different approach – fortunately the farm has a team who are up for that and owners who allow us to take a punt.”

Owned by Ian and Victoria Cammack, Newhouse Farm totals 800ha with 600ha cropped. A contract farming agreement is due to start after harvest this year, stepping up the arable operation to 1000ha. “For a while we were an AHDB Monitor Farm, and it was the bench-marking through the group that showed us we have the capacity to take on more,” notes Andy.

This has come about through a long-term plan to refine the arable operations. The farm has been following non-inversion tillage for 20 years. “It’s transformed operations, particularly on the heavy clay caps we have. We’ve found we can do less and less without compromising yield or establishment and have saved 40% in fuel across the farm.”

The cropping mix has also expanded, with peas, linseed, oilseed rape, winter and spring beans and spring oats grown alongside wheat. All spring cropping is preceded by a cover crop that’s rolled before being sprayed off with glyphosate to reduce the biomass. The crop’s then drilled direct with the farm’s 6m Horsch Sprinter, fitted with Borgault low-disturbance points.

“We take a slightly different approach with autumn cropping, making a shallow pass with a Lemken Heliodor soon after harvest to encourage a chit of volunteers and weeds,” Andy explains.

“OSR is the challenge at the moment, and we’ve tried companion crops of mustard and buckwheat without much benefit. This year we’re going to try a cover crop of buckwheat that we’ll then establish the OSR into in the last week of August.”

Alongside the cover crops and care with cultivations, there’s been a policy to reduce trafficking. “We’re not on a strict controlled traffic system, but we use RTK guidance to follow the same tramlines and keep passes to a minimum, with all straw chopped,” he says. The overall result is an average increase in soil organic matter of 1% since 2015.

All inputs are variably applied and Andy Bason (right) has reduced fertiliser inputs by 18% over the past eight years.

All inputs are variably applied and Andy is convinced of the benefits this brings in terms of targeting them more closely to the requirements of his crop across the undulating, variable soils. “We’ve reduced fertiliser inputs by 18% over the past eight years. It’s not about using less, though, but targeting it to where it’s needed and increasing our nitrogen fertiliser use efficiency (NfUE).”

That’s the current focus and Newhouse Farm is taking part this year in a major field-scale trials project, co-ordinated by CF Fertilisers, that aims to improve NfUE across the UK. Andy’s joined by CF’s head of agronomy Dr Sajjad Awan to talk through the initiative.

“Agrii and Frontier are also involved in these trials – altogether we have 75 NfUE field-scale trials across the UK – it’s the first time such a large, nationwide fertiliser trial has been undertaken into NfUE and should deliver some really valuable data and pointers for the majority of UK arable farmers. Our target is to reach 80% NfUE, while nationally it ranges between 50-70%,” he explains.

The trial involves taking a tramline in a field and comparing, side-by-side, the farm standard approach to determining fertiliser inputs with a more managed, targeted approach advocated by CF. Andy’s decided to take two fields – one of feed wheat, RGT Wolverine, while he’s aiming for milling quality from some KWS Zyatt.

“Our farm standard would be to give both 250kgN/ha,” says Andy. “The CF recommendation is to drop this to 190kgN/ha for the feed wheat and increase it to 300kgN/ha on the Zyatt to reach milling spec.”

Sajjad explains that, while RB209 is a useful guide for fertiliser recommendations, tools such as CF’s N-Calc, in conjunction with an accurate assessment of soil nitrogen supply (SNS), provide a far more refined approach. “It was a wet winter, followed by a cold start to the year, so overall SNS was likely to be low in many soils. However, this can be accurately assessed through the CF N-Min test that takes account of the additionally available N that becomes available as the soil warms up through the growing season.”

In addition to soil testing, leaf samples have been taken from wheat plants in the tramline trials and sent to Hill Court Farm Research, that produces a full analysis. “This helps refine the nutrition programme further, not just for N, but for other nutrients that contribute to NfUE – during crop stem extension the demand for sulphur is really high, for example. If the plant’s running short, that will hit NfUE at a critical time.”

Andy’s happy that the changes he’s making, further informed through the monitored trials, should bring positive results. “We’ve moved to a little-and-often approach on sulphur, applying SO₃ in compounds with the N at each timing. In the past we’ve struggled to achieve the milling spec, so hopefully a more measured approach will help us here, as well as reduce further our carbon footprint.”

Woodland on the farm is sensitively managed with thinnings processed and used as fuel for biomass boilers, displacing around 160kWh/yr from fossil fuels.

But it’s not just in the field where the carbon changes are taking place. The farm has 70ha of woodland that are sensitively managed with thinnings processed on farm to produce around 400m³ of woodchip per year. This is used as fuel for two biomass boilers in the main farmhouse and one of the farm cottages. A further log-fired boiler heats a third cottage, bringing the total energy generation displaced from fossil fuels to around 160kWh/yr.

“We’ve taken poorly performing land out of production and created a further 10ha of woodland,” adds Andy. “We’re working with Linking Environment and Farming (LEAF) and University of Reading on the EU Showcase 2020 project that aims to deliver new insight and innovative tools to help farming transition towards more sustainable farming.”

Andy’s involvement in LEAF underlines his fresh enthusiasm to pursue new ideas that integrate biodiversity into farming practices. Newhouse Farm is one of four taking part in Resilient and Ready, an intensive three-year programme of training, support and on-farm trials, run by Corteva Agriscience with LEAF. The aim is for Newhouse Farm to become a LEAF Demonstration Farm, showcasing what the team has learned to the wider farming community. The farm has also taken part in LEAF’s Open Farm Sunday, receiving up to 700 visitors, with plans for another event this year. It’s also hosted a visit from children of an inner-city primary school in Southampton.

“Community involvement is really important to us – it’s all very well doing the right thing, but it’s important to shout about it, too. It’s amazing the level of interest we’ve had and really rewarding to share our achievements and fulfil the thirst for knowledge kids have for what we’re doing on the farm.”

At this point, Andy gestures to another bare patch in the field, this one squarer and smaller on the field margin. “It’ll be our pumpkin patch and we’ll be inviting people to choose and pick their own. We’ve never grown pumpkins before so it might be a disaster, but we’ll enjoy finding out,” he says.

What makes Andy Bason a Climate Change Champion?

Innovative ideas

Innovative ideas

Andy’s enthusiasm and positive approach encourage a culture at Newhouse Farm to try new ideas, which are readily relayed to the farming and wider community. On-farm trials and drawing on authoritative advice, for example through LEAF, pave the way to a successful journey to a sustainable future.

Productivity push

Diligent improvements to the arable system have already delivered productivity benefits through input savings and these look set to continue with the current focus on NfUE.

Cultivation care

A gradual reduction in cultivations to a minimal approach, along with cover cropping and controlled traffic have led to an impressive 1% increase in soil organic matter over the past six years.

Bio-based boldness

Sensitive woodland management with thinnings used to heat the main farmhouse and cottages bring further net carbon gains, while 10ha of woodland creation secure future carbon capture.

Focusing on a low carbon fertiliser future

Fertilisers are going to have to work harder than ever in the future and not just with regard to their performance and cost-effectiveness on farm, says CF’s Sajjad Awan.

“Loss of nitrogen to the air, carbon footprints of production, ability to work reliably in changing climatic conditions, security of supply and minimising potential damage to soils – these and many others are increasingly important factors when deciding which fertiliser products to use.

“Helping growers improve their nitrogen fertiliser Use Efficiency (NfUE) to the 80% or above possible from systems using CF’s AN-based solid fertilisers is a top priority for us.

“But so too are investing in knowledge transfer across the industry and improving the efficiency of our manufacturing.”

CF supplies around 40% of the UK fertiliser market with its British manufacturing ensuring high production standards and a simple and reliable supply chain with minimum ‘fertiliser miles’, he points out.

“We are absolutely at the heart of UK food production and take our decarbonising responsibilities very seriously,” continues Sajjad.

“Working with the Carbon Trust as an independent auditor and verifier, we have produced carbon footprints for all our fertilisers as well as the ammonia and nitric acid used in their manufacture.

“We’ve also reduced the carbon footprint of Nitram production by 40% in recent years and are a key player in Net Zero Teesside and the Hynet North West carbon capture and storage initiative.

“But the difference will come on farm through those who are open to challenges,eager to trying new approaches and who strive for marginal gains to improve NfUE. We are delighted to work with Andy Bason on increasing the efficiency of his own fertiliser practices and proud to put him forward as our candidate for Climate Change Champion 2021.”

Climate Change Champions

UK Farming has set itself the challenging target of Net Zero emissions by 2040. Although led by the NFU, it will take the entire industry, working together in a partnership approach to meet this ambitious goal.

But there are individual growers, thought leaders who have already started on this journey. They have the ideas, the progressive outlook and the determination to shape positive change. CPM has teamed up with leading agricultural suppliers who have a credible Net Zero aspiration to identify these individuals and bring them into the top-level discussion about how farming can position itself as the solution to climate change.

CPM would like to thank our sponsors:

Agrii, BASF, BKT, CF Fertilisers, KWS, Interagro, Lloyds Bank, Small Robot Company]