A carefully managed programme of cropping, cultivations and complementary activities is helping a Kent farming business sequester impressive amounts of carbon. CPM visits to unearth the business opportunity this holds.

Agriculture should be at the forefront of delivering solutions for climate change.

By Tom Allen-Stevens

Admittedly it’s the first week of February, but there doesn’t seem much to see in the field of lucerne that Doug Wanstall is striding across. It’s not what’s happening above ground that counts, however.

He puts the spade in the clay loam soil and eases up a clod around one of the close-cropped plants. The first thing you see is a burst of worms, and then there’s a root that seems to go on forever. “A couple of years ago we dug down to see just how far they do go. We got to six feet and still hadn’t reached the ends,” he says.

The lucerne plant comes out of the ground with a burst of worms, while its roots seem to go on forever.

Lucerne is now part of the rotation on the 485ha farming business Doug runs with his father Richard and uncle Geoff. Alongside the arable cropping and forage, there’s a 74-head Sussex beef suckler herd and 12,000 laying hens that supply the diversified enterprises of the business, based at Aldington, Kent, with views across the Channel to the French coast.

Doug’s interest in lucerne stems from a Nuffield farming scholarship he took in 2015. In his travels across the world looking for resilient farmers, he was struck by how many grow alfalfa, as the crop’s more commonly known outside the UK. “I looked into its benefits for the arable rotation. It’s a legume you have in a 3-4 year ley that’s excellent at smothering out blackgrass. It’s also a high protein, productive forage crop. But best of all it’s deep-rooting and can bring an enormous improvement in soil organic matter.”

Another inspiration was the 4 per 1000 initiative Doug came across through the COP21 climate change summit held in Paris in the same year. The initiative notes that an annual growth rate of 0.4% in soil carbon would significantly reduce the CO₂ concentration in the atmosphere related to human activities.

“For me, this was a lightbulb moment,” says Doug. “Agriculture should be at the forefront of delivering solutions for climate change.” So he set up Re-Generation Earth that acts as “a conduit between those companies and individuals who want to take responsibility for their residual emissions and farmers who can sequester them”.

The lucerne is grown on around 120ha. “In the first year, you take around 4-5 cuts and every time you do, you take out blackgrass before it heads. We take 3-4 cuts in subsequent years, sold locally as hay or haylage while we also finish our suckler beef with it. We’re in discussions with a feed company to put in a pelleting mill that would turn it into a high protein feed in a more usable form.”

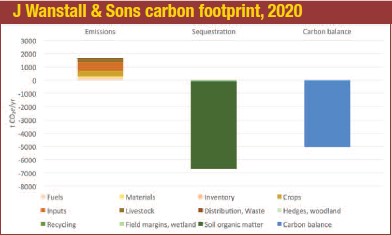

In addition, Doug estimates the crop captures about 40t/ha of dry matter into its roots, which translates into around 33t/ha of CO₂ sequestered. In four years, the average soil organic matter across the farm has increased by 1.5%, and this has brought about a massive difference to the farm’s carbon balance, ensuring the business is comfortably a net sequester of carbon.

But the lucerne is only part of the story. 2-3 year grass and herbal leys complement the crop, providing grazing for the cattle and for sheep, brought in under an arrangement with a local farmer. “We plant a diverse mix of species which ensures a good root content, drawing more carbon into the soil. The above ground biomass is converted into dung which feeds the soil processes.”

Doug also runs his own on-farm composting operation, based on the poultry litter and cattle FYM. “We bring in manure from local stables and also operate straw-for-muck deals with local farmers. This is then composted for two years before being spread on the land, which amounts to around 6000t of material annually,” he explains.

“This provides a considerable portion of the N, P and K the crop needs, but I believe it’s what you don’t see that really counts – the aim is to ensure the topsoil is biologically active to drive the carbon cycle.”

Doug’s on-farm composting operation (left) has helped raise soil organic matter by 1.5% over four years.

Here he highlights an issue with bought-in compost, however. “We moved away from buying it in because you don’t know what you’re getting. Even though it was certified, PAS100 compost, it contained small bits of plastic.”

This is part of a much wider issue that the industry is just beginning to get to grips with, according to Emma Ralph from Interagro, who joins Doug in a Zoom meeting to discuss the farm’s Net Zero journey. “Non-biodegradable microplastics, a legacy from years ago, is a concern for both soil health and watercourses. Greater scrutiny is required across every sector of the agricultural industry to ensure any microplastics used are biodegradable.” she notes.

On the cultivations side, although the tillage has reduced, the farm hasn’t quite progressed to no-till across a rotation that includes wheat, oats, barley and beans, and Doug retains his old “faithful” combination drill. “We don’t have a typical drilling or planting routine and used four different drills last autumn, with three of them provided by contractors – a Väderstad Rapid, Claydon Hybrid and Sumo DTS.

“The DTS and Claydon went in direct while the Väderstad often follows our 3m seven-leg McConnel Shakaerator. We need this, especially after the lucerne, as the ground gets a lot of traffic with the cutting and baling operations. The crop’s high root content takes the pressure without damaging the soil, but it does pack down a little tight for young cereal roots.”

The Shakaerator is undergoing a refit ready for the autumn with low disturbance legs and winged points aimed at creating lift without turning over soil. “The plan is to follow this with a disc drill as that’ll give us the best of both worlds,” notes Doug.

And this may be the same philosophy that’s behind his new agroforestry enterprise – the first field is due to be planted this spring with a somewhat unusual type of tree. “We’re planting the tree rows at 26m centres with 2m wildflower strips to maximise the IPM benefit. These will be planted with Paulownia Cotevisa, a very fast-growing hybrid that reaches the height of a 40-year-old oak in just eight years. It’s marvellous timber that’s hardwood but lightweight, referred to as the aluminium of the timber world, and it makes an excellent construction material.”

Doug points out this locks away the carbon for longer. “Like willow, you coppice it and it grows back. Meanwhile the roots grow deep, sequestering carbon and capturing leached nutrients without interfering with crop growth. Water quality is a big priority for the River Stour catchment we’re in that feeds the Stodmarsh National Nature Reserve – a wetland with protected status where phosphate run-off can be a serious problem.”

The farm’s diversified enterprises include the “egg machine” that sells all manner of farm-produced or locally sourced produce, via a self-serve vending machine.

This eye on the local market runs throughout the diversified enterprises the business operates, including the “egg machine” – a farm shop selling all manner of farm-produced or locally sourced produce, run from a container converted into a self-serve vending machine.

A more nationwide or even global appeal is Doug’s hope for Re-Generation Earth, though. “There are many farmers across the UK like us providing nature-based solutions to climate change and we’re working towards a set of standard metrics that will be accepted globally,” he says.

Emma notes that this again is a recognised issue within the industry as a whole. “What we desperately need is a level playing field. At Interagro we do everything we can to minimise our carbon footprint, but until there is one standard, recognised methodology to measure it, we can’t talk with confidence about what we’ve achieved, nor pass these benefits on to those who buy our products. It’s another area we’re working on with other manufacturers to get progress.”

For Doug, this can’t come soon enough. “There are a number of things we’ve done that have massively reduced our carbon footprint and put us a position where we can now sell carbon credits to offset residual emissions elsewhere. Farmers are uniquely placed to benefit from that, and now’s the time to stand up and be recognised for it,” he says.

What makes Doug Wanstall a Climate Change Champion?

Source: J Wanstall & Sons, October 2020, calculated using Farm Carbon Calculator. Figures shown are indicative.

Innovative ideas

Doug’s sequestering massive amounts of carbon into his soils and looks for every opportunity to turn this into a business venture to complement the farm’s diversified enterprises. The lucerne crop and agroforestry project in particular put the business in a strong position to benefit as a provider of climate change solutions.

Productivity push

Productivity from the cereals revolves around getting good biological activity in the soils. This has been carefully built up through the addition of composted manures and management of the grass and herbal leys, ensuring a very sustainable level of production.

Cultivation care

Soil movement is minimised to keep the carbon cycling in the uppermost layer. The lucerne enterprise in particular and the planned agroforestry venture take the carbon down deeper, making better use of the whole soil profile as a valuable resource. Biodiversity and water-quality benefits are built into the strategy.

Bio-based boldness

Re-Generation Earth has set a direction for the business to benefit from its net carbon-sequestering position – there are bright prospects in particular for the agroforestry timber as a carbon-friendly construction material.

Finding the root to make a difference

You’re unlikely to see much of the solutions that will help farming deliver Net Zero, believes Interagro’s Emma Ralph – they’ll take shape beneath the soil surface, and it’ll be those who seek to understand the root architecture they create who will make the biggest difference.

“Every farm will have different objectives, but achieving Net Zero will require the whole ag industry to work together,” she says.

“We see our role in finding low carbon-cost adjuvant and biostimulant solutions that will help growers capitalise on the opportunities they have to capture carbon as well as to help cut the carbon cost of current practices.”

Doug Wanstall not only recognises the climate emergency, but embraces it, Emma points out. “He pioneers solutions that harness the potential of roots to sequester carbon on his own farm, and takes the next step. He provides that conduit through Regeneration Earth, to offer other farmers and businesses the opportunity to reduce their carbon footprint too. That really makes him a climate change champion in our eyes.”

The journey to Net Zero is one Interagro has started, too, notes Emma, with a complete review of business from ground roots upwards. “We’re looking at every aspect – from employees to products, offices to cars and how the company operates. Our aim is to offer truly sustainable low-carbon solutions to farmers.”

For farmers the starting point will be their soils. “Our solutions have a pivotal role to play. Whether that’s biostimulants boosting the natural productivity of crops or adjuvants to help maximise efficiency and productivity of other inputs, they have a key role to play in allowing crops to reach their full potential and capture the carbon that’ll deliver a difference.”

Climate Change Champions

UK Farming has set itself the challenging target of Net Zero emissions by 2040. Although led by the NFU, it will take the entire industry, working together in a partnership approach to meet this ambitious goal.

But there are individual growers, thought leaders who have already started on this journey. They have the ideas, the progressive outlook and the determination to shape positive change. CPM has teamed up with leading agricultural suppliers who have a credible Net Zero aspiration to identify these individuals and bring them into the top-level discussion about how farming can position itself as the solution to climate change.

CPM would like to thank our sponsors:

Agrii, BASF, BKT, CF Fertilisers, KWS, Interagro, Lloyds Bank, Small Robot Company