The Lockerley Estate in Hants has made impressive headway on its journey to be a progressive, sustainable and successful farming business. CPM visits to find out how robots will lead it on its next stage.

What’s fundamental is to have the confidence not to do something.

By Tom Allen-Stevens

Craig Livingstone’s fork receives a ‘ching’ as he attempts to free up a clod from beneath his oat crop, indicating his predominantly chalky soil, with its stone content and clay caps, is not going to give up its secrets on this dry, warm day in June.

“You have to have a respect for the soil – an unofficial conversation with it,” he says. “There are changes we want to make here at Lockerley, opportunities we feel we’re well placed to take advantage of. But we have to earn the right for the soil to respond.”

Winter oats are low input, yield well and go to a premium market, while in-field ASSIST strips increase the population of beneficials within the crop.

You could say Craig has already earned that right. Since he arrived as farm and estate manager at the Lockerley Estate in Hants five years ago, the pesticide spend has reduced by 41%, the amount of inorganic fertiliser used by 32%, while the organic matter of the soils (SOM) has increased on average by 1.1%. Lockerley has also become a LEAF Demonstration Farm and is LEAF Marque Accredited.

“The biggest change for us as a team has been mindset,” says Craig. “We’ve taken everything in hand, from woodland management, to agronomy, to administration of subsidies and financials. We’ve achieved efficiencies with how we work, and know we can do more.

“But what’s fundamental is to have the confidence not to do something – whether that’s reduced cultivations, lower crop inputs or taking areas out of production altogether.”

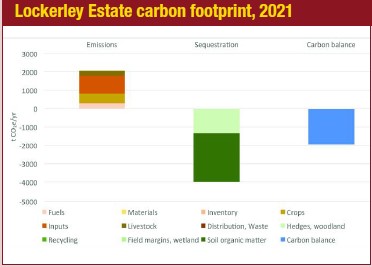

Craig refers to it as a “recalibration” – harnessing the skills of the estate team on their mission for it to be a progressive, sustainable and successful farming business that champions a regenerative approach. “So we have the opportunity to sequester carbon, for example. But we must fully understand the carbon issues first – accurately measure our emissions, understand how we can reduce the use of inorganic fertiliser, and how that affects the ability of living roots to sequester carbon.”

The estate has plenty of natural capital assets to draw on that Craig points out as he drives back to the farm office. Owned by siblings of the Sainsbury family, there are 800ha of arable cropping, 235ha of woodland and 30ha of permanent grass. There’s a rewilding project, two sites of special scientific interest (SSSI) and a special area of conservation (SAC). It’s part of the 5000ha Wallop Brook Farmers catchment – a project focusing on farming practices surrounding the SSSI chalk stream that passes through.

“We farm 11 different soil types from Upton chalk to Givendale clay and much in between,” continues Craig. “One of the first aspects I wanted to understand was what our farming practices are doing to these.” So he’s taken five representative points on the estate, accurately mapped using What3Words, on which a full soil analysis is taken annually.

Since the start of a change to regenerative farming principles the results have shown an average increase of the mean SOM from the five sample points from 4.1-5.2% using the Dumas SOM test. So how has this been achieved? “When I first arrived, all fields were cultivated twice to 175-200mm with a Väderstad Topdown. We quickly reduced this to around 75-100mm, and now make more use of a Väderstad Carrier L with cross cutters and Biodrill, going shallower again – around 50mm. It’s not only built SOM, but saved labour and machinery costs.” Craig gestures to the farm’s John Deere 8360RT crawler tractor that’s gathering dust, stuck behind a topper in the shed opposite the office.

This spring, the estate dipped into direct drilling for the first time with 160ha of spring crops, trying out a 6m Virkar single-disc drill borrowed from Lockerley’s sister estate 30 miles away. “It was a success, but we’d earned our right to do it. In farming you can’t afford failure. So we’ve taken our time and built our confidence over six years.”

They’ve also built up the system around it. Back at the estate office, Craig explains that the rotation has moved from wheat/spring barley/oilseed rape to one that includes oats and winter barley. “We’re growing Maris Otter, which at 6t/ha will never outyield hybrid barley. But it uses less fertiliser and the net margin on this land is better,” he says as he flicks through the figures.

Peas and beans are now the main break crops, with OSR dropped as a result of cabbage stem flea beetle pressure. More than 200ha of cover crops are grown with diverse mixtures majoring on phacelia, buckwheat and clovers. These are grazed by a 1200-head flock of sheep, brought in under a partnership arrangement with a local shepherd. They’ve resulted in a 28% reduction in nitrogen fertiliser for malting barley following cover crops and a more consistent grain sample.2000t of organic manure and compost are imported each year and add to the soil improvement picture.

So what about productivity? “Winter oats produce the best margin because they’re a very low input crop, yield well and we will soon be supplying Jordans as a LEAF Marque farm. Spring beans are a risk, but you have to look at the contribution across the rotation as a whole – that’s where the benefits come, and the pulses have considerably reduced our fertiliser and cultivation requirement,” notes Craig.

The next stage on Lockerley’s journey may be non-chemical weeding, and Dick the weed-zapping robot prototype has visited the farm.

The next step on the productivity journey has made its first forays across the farm over the past nine months in something of a ground-breaking step, not just for Lockerley, but for agriculture. The estate was one of the first in the UK to have a field mapped by Tom, the scouting robot from Small Robot Company.

The pilot service, costing £40/ha, included four scans in the autumn and a further three this spring. All 12.7M plants across 6ha of a 35ha field were logged and monitored at each scan, around 250,000 of which were found to be weeds. “I view this as another card in the deck that gets us towards our progressive, sustainable goal, marrying the most traditional methods of good mixed farming with the latest technology,” notes Craig.

“The massive opportunity is in non-chemical weeding, but the granularity of the information you receive for every plant in the field has potential far beyond that. I could go into Wilma – the user interface – and have a look at what Tom found. He zeroed in on a 3-4ha patch containing blackgrass and the detail of the map produced was simply amazing.

“One interesting aspect was the way the autonomous bot worked – it wasn’t a particularly fast work rate, but they tested him at night, too. The results were consistent, which was a bit of a landmark moment for the technology, I understand.

“Going forward, I don’t think I’d use Tom over the whole farm, but focus his input on areas that would bring greatest returns – patches of blackgrass or areas of variability where a per-plant understanding could help us reduce fertiliser use by, say, 50%,” he enthuses.

“The technology’s come a long way in just 12 months, and there’s talk Tom will be used to listen for birdsong to log biodiversity indicators, smell the soil and seek out slugs. The next stage of robot farming may be non-chemical weeding, and Dick the weed-zapping bot has visited the farm. It’s impressive how he locates and fries the weeds with electricity, although commercial application is still some way off.”

Outside the core arable enterprise, Craig explains that the estate is involved in a number of projects looking to enhance its biodiversity, as well as build its carbon stocks. A new Higher Tier Countryside Stewardship Scheme will start next Jan, subject to approval, taking about 14% of land out of production and into environmental measures. This includes ASSIST strips – 6m wide pollen and nectar margins established in the middle of fields parallel to tramlines to increase the population of beneficials within the crop.

30ha surrounding the SSSI and SAC areas have been developed into a rewilding project with a small herd of Longhorn cattle introduced for natural grazing. 10,000 hedgerow plants have been established in the last three years adding to the 20km on the farm, while over 100,000 trees, mostly new woodland, have been planted since 1983 as the estate has moved towards restocking its woodland with continuous cover, rather than clear-felling.

One of the few remaining bags of flour, bagged up for home-baking enthusiasts and sold to the local community.

There’s a strong financial element to the changes, though. Craig pulls out an Agricultural Transition Roadmap he’s prepared, that shows how he plans for the loss of the Basic Payment Scheme to be balanced – there’s a notable gap in income that develops by 2028.

“Being part of the Wallop Brook Farmers catchment isn’t just about doing what’s right for the chalk streams. We’re positioning ourselves for ELMs Pillar 2 funding.”

He also draws a distinction between the estate’s actual net zero, that’s already been achieved, and operational net zero. “We have natural assets sequestering carbon and a 50kW solar array. But the challenge is for the farming carbon footprint to be zero. So we have a project this harvest looking at switching our 12,000 litres/yr of red diesel used in the continuous flow drier to hydrotreated vegetable oil, for instance.”

Craig has reservations about current carbon calculation tools and believes that if farmers learn to get the operational carbon accounting right, the markets for traded carbon will develop. “If we’re led into trading carbon without understanding how to fix the problem first, we may come up against problems further down the line,” he notes.

And he reckons there are local market advantages in this quest. The estate has opened a Veg Shed, with ecologically grown vegetables and home-sourced venison and lamb sold to the local community. Working with a local mill, they’ve also bagged up several hundred packs of flour for home-baking enthusiasts.

Craig picks up a couple of packs from the few that remain and are sitting in the corner of the office. “The demand for these during lockdown was staggering and we’ve already run out of our strong bread flour,” he says.

“I think these opportunities will only increase, especially if we put in elements, such as what we’re doing with the Small Robot Company, to disrupt the industry, to force it to ask questions about how food is produced and the carbon cost of resourcing this.”

Craig glances down at the Lockerley Estate branded produce in his hand. “I’m looking forward to selling the UK’s first bag of flour that’s both grown to regenerative principles and produced by robots,” he says.

What makes Craig Livingstone a Climate Change Champion?

Source: Lockerley Estate, 2020, calculated using Farm Carbon Calculator. Figures shown are indicative.

Innovative ideas

Craig’s focus is to use the best of technology, combine this with a recalibration of ideas – a change of mindset within the team at Lockerley – to deliver the estate’s mission. This is clearly stated, and his progress towards the estate’s goals are well evidenced.

Productivity push

Behind the headline achievements there’s a planned approach to maintaining or increasing output sustainably, while lowering resource use with confidence. Craig plans to make greater efficiency gains through increasing the level of detail and granularity of the data he captures.

Cultivation care

A measured reduction in cultivations has ‘earned’ the estate its right to go no-till. A respect for the soil has driven impressive gains in organic matter content.

Bio-based boldness

Although the estate is clearly carbon positive, thanks to good use of its natural assets, Craig makes a distinction with the farm’s operational carbon balance, that he also plans to bring to zero.

Robot nose sniffs soil for the carbon clues

The Lockerley Estate is involved in a potentially game-changing soil health monitoring project. Soil samples were collected this spring by scouting robot Tom and analysed on-the-fly for Volatile Organic Compounds (VOCs). This autumn, in the next phase of the trials, soil samples will be collected from five known locations on the estate which have been tracked for the last five years. These will be ground-truthed by sending the samples to a lab for analysis, and the results compared with the historical data.

Funded by UKRI, the project consortium comprises PES Technologies, Small Robot Company (SRC), NIAB-EMR, Hutchinsons, and the Universities of Essex and Greenwich. The proof of concept has been achieved with the robot successfully taking and scanning 400g samples of farmland soils. The consortium is using machine learning approaches to profile soil health directly in the field by measuring soil gases. These microbial VOCs are effluxed by various soil types and cropping systems – it’s the first time they’ve ever been used to gauge soil health.

PES Technologies has developed the robot’s “nose” – a soil health analysis tool that detects the VOCs. The tool’s output data is related to a variety of biological, chemical and physical soil health indicators, including microbial biomass and SOM content, by analysing the activities and diversity of a soil’s microbial community.

SRC’s Sam Watson Jones believes robotic monitoring could provide accurate, repeatable carbon measurement at farm scale. “The UK – and UK agriculture – have made bold commitments to Net Zero,” he says. “Robotics can already take billions of accurate measurements in each field. These will transform the way that farms are able to sequester and cycle carbon, and measure that accurately. The opportunity for UK (and global) agriculture to support the transition towards Net Zero is enormous.

“For the individual farmer, this technology is empowering. Craig has already shown how a respect for the soil can result in massive improvements in its health. It’s the steps he’s taken, along with a determination to use the best technology to go further, that makes him a worthy Climate Change Champion.”

Climate Change Champions

UK Farming has set itself the challenging target of Net Zero emissions by 2040. Although led by the NFU, it will take the entire industry, working together in a partnership approach to meet this ambitious goal.

But there are individual growers, thought leaders who have already started on this journey. They have the ideas, the progressive outlook and the determination to shape positive change. CPM has teamed up with leading agricultural suppliers who have a credible Net Zero aspiration to identify these individuals and bring them into the top-level discussion about how farming can position itself as the solution to climate change.

CPM would like to thank our sponsors:

Agrii, BASF, BKT, CF Fertilisers, KWS, Interagro, Lloyds Bank, Small Robot Company]