With higher-yielding quality wheats making it hard for growers to meet the full protein spec, perhaps it would be easier if breeders designed a wheat that made a decent loaf with lower protein. CPM assesses the science.

We’ll be looking in some detail at how the protein functions.

By Tom Allen-Stevens

It’s a lucky number for some, but for most growers 13% protein tends to be a target they fail to achieve, according to the AHDB Cereals Quality Survey. Just 31% of Group 1 wheat samples from harvest 2015 achieved the full bread-making quality spec, and protein is cited as the main limiting factor – 37% of samples were 13% or above, while 90% of samples exceeded 250 Hagberg and 92% attained the required 76kg/hl specific weight.

It’s a lucky number for some, but for most growers 13% protein tends to be a target they fail to achieve, according to the AHDB Cereals Quality Survey. Just 31% of Group 1 wheat samples from harvest 2015 achieved the full bread-making quality spec, and protein is cited as the main limiting factor – 37% of samples were 13% or above, while 90% of samples exceeded 250 Hagberg and 92% attained the required 76kg/hl specific weight.

What’s more, unless the issue’s addressed, it’s a figure likely to drop even further, warns Dr Dhan Bhandari of AHDB Cereals and Oilseeds, and protein’s not necessarily a hard-and-fast measure of baking quality.

“The suitability of a wheat for baking is not straightforward, and the final product can be a matter of opinion. A protein content of 13% doesn’t guarantee a good loaf, and it may be possible to produce a suitable grist from wheats with a lower protein. But millers and bakers still prefer a wheat at 13% because, in the absence of anything more effective, it’s still the best indicator of likely quality we have at the moment,” he explains.

Protein dilution

In newer quality-wheat varieties, protein dilution – where applied nitrogen is used by the crop to feed the higher yield potential, rather than grain protein content – is a recognised problem that’s set to get worse, he says.

“There are several high-profile research projects and programmes underway aimed at lifting wheat off its yield plateau, with 20t/ha being the aim often quoted. If this is successful, breeders will be focused on converting N into starch, and achieving a 13% grain protein level in the future could become even harder.”

Fortunately, research has also been underway to unpick the vagaries of protein content and how it relates to baking quality. A three-year project that completed in Sept 2012, funded by BBSRC and industry partners, including AHDB, identified sets of genes, related to grain protein, that responded to N applications.

“This project resulted in a better understanding of the causes of variation in protein – not just content, but also its quality – in six, selected commercial varieties,” continues Dhan Bhandari. “We now know much more about the regions of the wheat genome, or quantitative trait loci (QTL), responsible for baking quality influenced by grain protein and how agronomic practice influences these.”

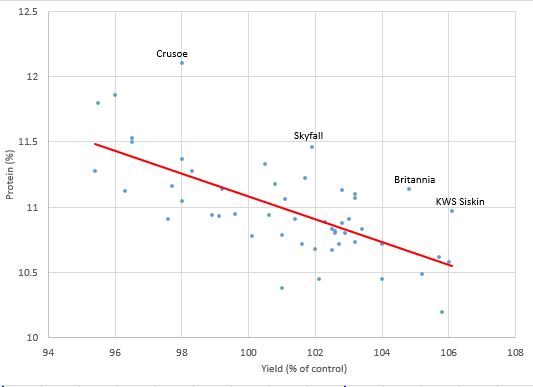

Crucially the project addressed the question of protein dilution. There’s an inverse relationship between yield and grain protein for most UK wheat varieties (see chart on pxx). “Some varieties buck that trend,” he notes.

“The next step in the challenge is to explore the QTL – look further afield to see how they differ between wheat types and what will happen to the QTL when you cross varieties. Can we use this knowledge to develop new types of wheat with good bread-making quality at low protein content?”

So a new industry-funded project is now underway which has that aim (see panel on pxx). A wider range of varieties

If breeders are focused on 20t/ha wheats, then achieving a 13% grain protein level in the future could become even harder, warns Dhan Bhandari.

are under scrutiny, looking not just at protein deviation but studying the protein composition in more detail. “Researchers will be looking for the gluten fraction that delivers the desired visco-elastic properties,” says Dhan Bhandari.

This will result in genetic markers being identified which breeders can use to help develop new lines with the right, stable proteins for bread-making. What’s more, the project aims to develop a more reliable test of the suitability of wheats for bread-making.

“The current test is very crude. The only true way to test flour is to gather enough to bake it, which doesn’t help breeders who are looking for a reliable way to screen new lines.”

Not absolute

One option to consider could be a method developed by the French applied research institute Arvalis. High performance liquid chromatography (HPLC) involves using a tiny quantity of flour and testing it for the nature of the proteins it contains. “It’s not absolute, but it may be a useful screening tool. What’s needed is further evaluation with UK varieties,” he notes.

The new protein project got underway in Jan this year. Already in the ground are trials of 40 different varieties that will come under scrutiny this harvest, reports project lead Prof Peter Shewry of Rothamsted Research.

“What we’re looking for are not necessarily wheats that consistently achieve 13% protein, but varieties that will be suitable for bread-making at 11-12%. We know this property is largely defined by gluten quality, so it’s a case of studying wheats we believe have this potential in more detail,” he says.

The varieties have been chosen either because they are known to have a more stable quality profile or because there’s anecdotal evidence that suggests this. There’s a mixture of wheats from across Europe – some older UK lines, such as Avalon and Cadenza, join Hereward and Soissons and some more recent additions to the AHDB Recommended List, as well as some candidate varieties.

“We’ve worked with the breeder partners on the project to source a wide selection of material – there are two hybrid wheats, some from Germany and several from Hungary.” These are grown under two nitrogen regimes, and then the harvested grain will undergo thorough testing.

“We’ll be looking in some detail at how the protein functions, but we’ll also develop tests that work at low protein levels and can be used by breeders and millers.”

At JIC, work will exploit knowledge of the genetic control of bread-making quality to develop improved cultivars, he continues. “Our previous work identified genetic markers for large QTL associated with quality, such as loaf volume and crumb structure. We’ll now bring all of these quality QTL together and ultimately create a perfect wheat for the low-protein, quality loaf.” These combined QTL could be taken into breeding programmes, or breeders could combine a few stable QTL into their lines.

“Through the course of the project, we hope to develop rapid tests and markers for wheat breeders and grain processors, and material to help millers and bakers optimise their processes.”

The HPLC test is one that could hold potential to give greater insight into a variety’s performance, believes AHDB RL manager Dr Simon Oxley. “This tests the proportion of functional glutenins and gliadins and the non-functional proteins,” he explains.

Depending on the end use, a miller or baker is looking for a flour to contain the right proportion of glutenins and gliadins. “The glutenins provide the elasticity, while the gliadins tend to give the dough extensibility.”

Working with Campden BRI, some pilot HPLC tests were carried out on a few samples from the RL trials from the 2014 harvest. The protein content of five varieties was analysed, and the results from three sites –in the East, the Midlands and in the far West – were compared.

“The protein content of each variety differed. But what surprised me was that for one variety, there was a greater proportion of non-functional protein in the sample from the East than the one taken from the West. If we had this detail on protein quality for all varieties, we’d be able to differentiate site effects better.”

He’s keen for a research project to look at this area in more detail, using the samples from the RL trials. “Understanding a bit more about the variety components might help us assess the quality of the protein. That’ll help inform about suitability for particular markets – end users already do their own tests for breads and biscuits, but what about niche uses?”

It would also help gauge the consistency of protein quality. “We have RL information that gives a measure of consistency of yield, but nothing when it comes to quality,” notes Simon Oxley.

This sort of research may bring growers immediate benefits, in terms of clearer information on variety performance through the RL. But pre-breeding work has a much longer timescale, notes Dhan Bhandari.

“Projects such as these may not translate into on-farm benefits for as long as 15 years, but it’s important for AHDB to be involved,” he says. “We’re there helping to direct the work to ensure it addresses growers’ needs, and we play an essential role in engaging end users with growers, so outcomes have mutual benefits.

Peter Shewry wants to study varieties that are suitable for bread-making at 11-12% protein.

“What’s more, this is a relatively small investment for AHDB, for a significant body of research that will give millers and bakers much greater confidence in quality parameters that currently don’t bear much scrutiny. The active participation of some of the leading UK flour milling and baking companies clearly shows how important this type of fundamental research is to this sector of the industry,” he concludes.

- Prof Peter Shewry was recently awarded the Clyde H Bailey Medal, the most prestigious award offered by the International Association for Cereal Science and Technology. Granted just once every four years, it was awarded for his outstanding research on wheat and other cereal grains, ranging from grain structure and functionality to molecular genetics.

Grain protein deviation in UK wheats

Hoping to redefine how protein is viewed

The difficulty KWS wheat breeder Mark Dodds has when selecting wheat varieties for quality traits is that he’s not entirely sure what he’s aiming for at present, particularly when it comes to protein.

“All millers have different requirements, and then there’s the need for it to be consistent over years and reliably within these requirements,” he explains.

“What’s more, the primary focus has to be yield – new lines don’t get into official testing unless you can demonstrate a yield advantage. That doesn’t mean protein’s forgotten, but it will come under increasing pressure as a result of the dilution effect.”

All varieties in his programme are routinely screened for quality traits, but a reliable test remains a challenge, he says. “You can get a picture of protein amount early on, from just a 15g sample, which helps us discount a lot of lines. But you can’t do a positive test until you have a plot large enough to harvest and try a test bake – that’s at least five years from the initial cross. Anything that can give us a positive indication early on would be a huge help.”

It’s one of the reasons KWS is on the consortium of industry partners involved in the current pre-breeding research, he says. “The aim is to retain the functionality in the wheat even with higher yields that may dilute the protein.”

The company has its own pre-breeder, dedicated to researching traits, but a project of this scale is not one that could be tackled by one breeding company on its own, he points out. “It’s a huge project, involving some of the best experts in their field from Rothamsted, Campden BRI and JIC. Success in pre-breeding work is a rare occurrence, so you need a project of this size to ensure results.”

Once the project bears fruit, the partners on the consortium will be the first to benefit – a breeder’s ‘toolkit’ that may consist of genetic markers or small-scale tests that could be used to better predict quality in early generation breeding material.. “It’s only a step along the way, but an important step,” notes Mark Dodds.

“There’s no one gene that governs traits such as yield or grain quality – there’s a whole heap of them. Finding and understanding more genes that control quality would allow breeders to utilise them to improve UK wheat. Without this type of project, it would be a slower, more complicated job bringing new varietal developments to the market place,” he explains.

Although the results won’t be seen on farm for some time, he feels there’s a need to redress the imbalance with most wheat in the UK currently grown for feed. “We reckon a third of the market should be hard milling wheats, a third soft milling and the rest feed varieties. The point of KWS’ Dynamic wheats is that you decide what protein level and what market you want to target, without a yield penalty.

“But one of the key aspects of this project is that its aim is to find new wheats with the right functionality that don’t need a 13% protein spec – it could ultimately change how quality wheat is traded in the UK, let alone how it’s bred.”

Research round-up

AHDB project 217-0005, Developing new types of wheat with good bread-making quality at low protein content, runs from Jan 2016 to Dec 2019. Its aim is to facilitate the development of new types of wheat through screening selected cultivars and lines to identify genetic sources of stable quality at low protein content. Its total cost is £1,040,000, with BBSRC as the Government sponsor and industry partners Campden BRI, DSV, KWS, Limagrain, Secobra, ADM, Heygates, Warburtons and Whitworth Bros. AHDB funding amounts to £80,000, with the research carried out by Rothamsted Research and JIC.