A group of progressive growers met recently to gain a deeper insight into how to optimise their wheat’s performance. CPM joined them and brings an exclusive report.

We effectively have around 100 days from when the crop wakes up in the spring until it senesces to make it yield.

By Tom Allen-Stevens

As spring growth gets underway, there are two questions many growers will probably be asking themselves: ‘How has the wheat crop fared through the winter?’ and ‘What’s the surest way to get it to perform at its best by harvest?’

There’s one group of farmers that’s keener than most to know the answers. The Bayer Xpro Farmers Club (XFC) is a group of progressive growers from across the UK who meet regularly to discuss technical issues and in particular how to optimise winter wheat performance. Most of the farmers have also joined the Yield Enhancement Network (YEN) and have been looking in more detail at how to manage crop growth to achieve this (see below).

The individual situation and location of a crop will determine its potential long-term average yield.

“We effectively have around 100 days from when the crop wakes up in the spring until it senesces to make it yield,” notes Northants grower Andrew Pitts. “We have to ensure every day contributes towards that.”

On Terrington Marsh in Norfolk, Mark Means is keen to ensure his crops aren’t sink-limited and are managed to ensure they have the capacity to yield. “There’s also the worry that if you push them too hard, they’ll lodge.”

Russ McKenzie, on the Cambs, Beds and Northants border, is looking to focus on optimising early canopy and crop structure. “Getting biomass and preserving or manipulating tiller numbers are critical to achieving high yields,” he reckons.

But Andrew Williamson in Shrops worries whether keeping the biomass alive for longer takes yield out of the ear. “Late-maturing Revelation always looks like it has monster ears, but doesn’t perform for us as well as earlier maturing JB Diego.”

For Roger Hopley in Staffs, making the N available to the crop when it needs it is a key concern. “In April, ground conditions are often too dry,” he notes.

While attention to detail on trace elements holds the key for Essex grower James Mayes. He’s keen to improve his understanding of what they can do. “These are far more on our radar than they were before – we’re aware of them but we’re not experts.”

So Bayer’s brought the group of around a dozen growers together with a number of leading industry representatives to provide insight into some of these areas. The principle explored in YEN is to work out the biophysical potential yield of a crop, explains ADAS scientist Dr Mark Ramsden.

“A crop’s yield potential is based on the availability of incident light energy and the ability of the crop to capture this resource and convert it into biomass. This conversion requires water, drawn up by the roots from the soil. The yield potentials of crops in the East are commonly limited by the availability of water, while in the North and West, light is more often the limiting factor.”

The individual situation and location of a crop will determine its potential biomass, and a harvest index of around 60% will give you a potential yield. “The long-term average across the UK is 21t/ha of grain at 15% moisture. In Cornwall, it’s more like 24t/ha, while in East Anglia and the North East it’s 20t/ha,” he adds.

The success of growers in managing their crop will determine how much of this potential yield is realised – in 2017 the highest actual yield in the YEN was 15.3t/ha, while the highest proportion of potential yield was 83%. Key areas to focus on are nutrition and green leaf area duration (see below).

“The first step is to assess where you are,” advises Mark Tucker of Yara. “You’re aiming for 600 ears/m², so it’s a good idea to assess shoot numbers early on.”

A low biomass crop above ground suggests a low root mass below, too. “That affects nutrient uptake and nitrogen use efficiency (NUE). If your crop’s behind, it needs extra N early on. So if your early dressing is 40-50kgN/ha, a good target is 80-100kgN/ha.”

March and April tend to be two of the driest months, which could slow uptake of applied nutrients, he continues. “So the more N we can get into the crop early on, the more chance there is of getting a return on that N.”

It’s also worth finding out your soil nitrogen supply, and Mark Tucker notes that organic matter will increase NUE. “If you keep a zero-N plot within your crop that will tell you how much N is naturally available.”

Once you’ve succeeded in building early biomass with an early N dressing, it’s important to keep the crop well nourished throughout the growing season by carefully balancing subsequent dressings, he continues. “The best way to assess this is with an N-Tester. The guideline states you should keep the crop at 3%N, but that’s for the whole crop – the leaf wants to be at 4%N, or between 4-5% for a milling wheat.”

Other nutrients are crucial – a performance crop should want for nothing, Mark Tucker notes. “It’s a good idea to get tissue tests during the season, but the results need to be interpreted. Plants have a big demand for potash in spring, but it’s often not picked up in dry weight analysis because K is carried in solution. Don’t look at one result in isolation – a declining K is what to look out for.

Phosphate that’s apparently available in the soil may be locked up, he continues, and a tissue analysis will reveal this. “It’s needed in relatively low amounts, and P availability is at a minimum when the soil is coldest at the start of spring. So an early foliar dose can be a valuable boost, or fresh solid P applied in the spring will be readily available as soon as soils warm up.”

Sulphur doesn’t move in the plant, he adds. “Again, don’t just rely on one tissue test to tell you availability, and make sure there’s S available at the end of the season to feed the ear.”

Micronutrients, although needed in small amounts are crucial. “Often overlooked are copper, zinc and boron. A lack of any one of these will limit grain numbers in the ear. But analysis results show six out of ten crops are short of Zn, four out of ten lack Cu while 80% of crops go short of Bo.

“Yara’s currently undertaking work to refine guidelines on Bo management – the demand is low during tillering, but there are times, such as at GS39, when the crop demand is much higher,” notes Mark Tucker.

Early start ensures a late finish

Extending GLA through fungicide use

Having a leaf canopy that captures the available sunlight and turns it into energy is crucial to optimising yield potential. The key to this is keeping those leaves green for as long as possible, according to Bayer commercial technical manager Gareth Bubb.

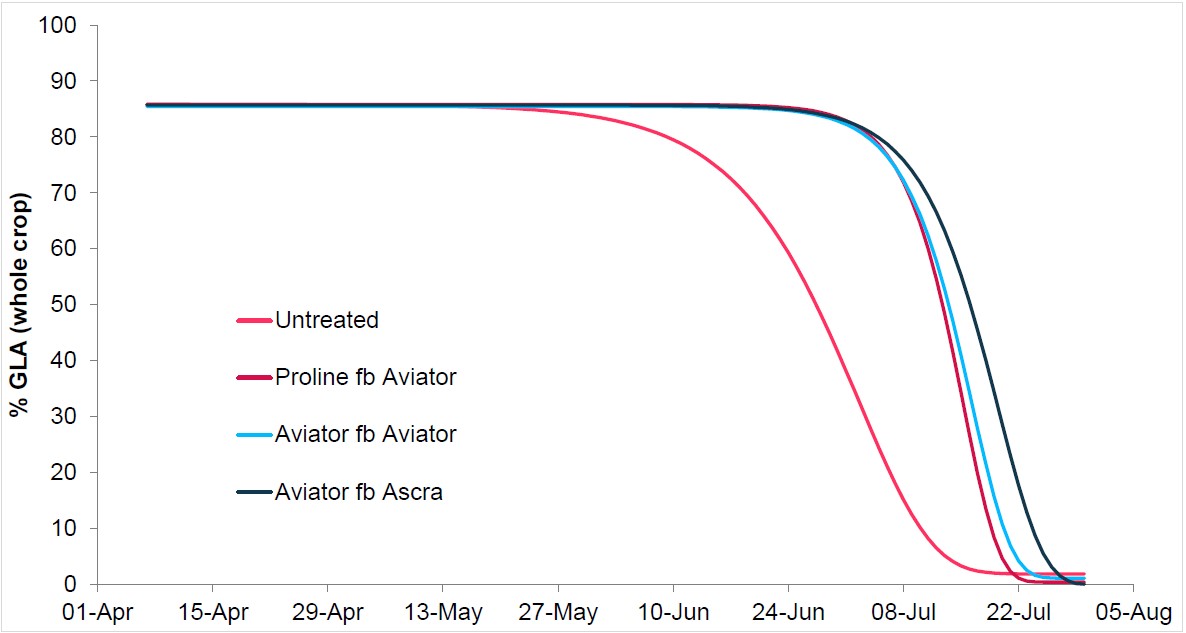

“If you’re pushing your crop for yield, keeping it greener for longer will make all the difference,” he says. In fact, it makes a difference on average of 0.45t/ha per day that green leaf area (GLA) is above 35%, according to Bayer trials carried out over the past three years, with analysis carried out by ADAS.

“The trials in 2016/17 on KWS Santiago showed an extra 13 days GLA duration over untreated for a Proline (prothioconazole) T1 spray application followed by Aviator (bixafen+ prothioconazole) at T2 (see chart). This nudged up to 14 days where two SDHIs were used. The best result, at 18days, was Aviator, followed by Ascra (bixafen+ fluopyram+ prothioconazole),” reports Gareth.

So how is season-long GLA achieved? “It starts with the early sprays – the aim here is to keep disease out of the crop that will affect GLA later on,” he explains.

“The T0 buys you time and is mainly about protecting the crop from early septoria with chlorothalonil (CTL). If yellow rust is a risk, an azole, such as tebuconazole or cyproconazole will bring about three weeks protection. A strobilurin at T0 will stop rust quicker, but won’t last as long.”

He advocates an SDHI at T1, unless it’s a variety with a strong septoria disease rating sown relatively late. “In other situations, variety ratings are all well and good, but every day before 1 Oct the crop was sown will knock back a variety’s septoria score.”

Of all the applications, the T1 is the most difficult to time right, he notes. “You have to give leaf three a good covering, regardless of what you do at T0 or subsequently. The T1 and T2 are the timings you cannot mess around with.”

If it’s a susceptible variety, the T1 has gone on early and there’s likely to be a long interval between that and T2, you could be pushed into a T1.5, he says. This may also be the case if the weather is ideal for yellow rust development.

There’s also potentially a long period after the T3 to keep the leaf green. “We have done some work showing a benefit from using an SDHI at T3, rather than T1, but if you let disease in at T1, you’ve already lost the battle. There’s little value in a T4 spray, unless brown rust is a problem.”

Keen to nurture the crop potential

Russ McKenzie would like to look more closely at ways to manipulate ear and grain numbers to optimise what is produced.

The late start to the spring is beginning to make the XFC growers nervous. “We’ve had a really wet winter, but most of our wheats are looking OK, especially the more forward ones,” notes Andrew Pitts.

Skyfall, Elicit and LG Motown make up his 500ha of wheats on chalky boulder clay at Grange Farm, Mears Ashby. “I’d like to have put 100kgN/ha early on all the later drilled crops, and only put a bit on,” he reports.

“We have become more focused on feeding crop potential since being involved with YEN, and apply between 30-80kgN/ha more over the season, applied in 4-5 splits rather than three. We aim for a GAI of 6+ at maximum canopy and are seeing yield benefits where we get the crop structure right.”

In the lowest part of the Wash on silty clay loam, Mark Means is most concerned about his spring crops. KWS Barrel, KWS Zyatt, Gallant, Cordiale and a little KWS Siskin make up his 450ha of winter wheat.

“Oct-drilled crops in fertile situations are looking good. The frost has hurt the Nov-drilled wheat after sugar beet, but we have given these a bit of early N and they’re looking OK.”

His was the best-performing crop in the first year of YEN in 2013, and his wheats routinely receive a T1.5 spray. “it’s a good timing for broadleaf weeds and growth regulator, and adding some CTL covers leaf two at the right time 10-14 days before flag leaf emergence. Later in the season it’s about coaxing the crop to keep the grain sites going with trace elements and other building blocks,” he says.

Russ McKenzie reports that his 429ha of Siskin, Zyatt, KWS Crispin, Gleam, Elicit and Shabras at Tebbit’s Farm are “generally OK”. “The latest drilled wheats could do with a bit of encouragement, and anywhere that had a degree of water logging looks pretty horrible, although fortunately that’s not very much.”

He prioritised N on second and late wheats in the brief window in late Feb. “I’m concerned that some crops may be losing potential and backward crops are going to need front loading with N to try to boost canopy development. The problem is that window is closing rapidly as we physically can’t get on.”

Andrew Williamson’s 120ha of Siskin, KWS Lily, Graham and JB Diego wheats are looking “cold with wet feet” on silty clay loam at Upper Overton Farm near Bridgnorth, but he’s not unduly concerned.

“Normally they’d have some N on by now – we’ve upped the early dose since being involved in YEN from 40kgN/ha to 70-80kgN/ha to build early biomass. We’ll then monitor with the N-Tester for the rest of the season. All the YEN data shows you get better crops later, but it’s our early maturing crops that perform better – we want to look closely at that.”

Although he’s been an XFC farmer for around four years, this is the first year Roger Hopley, at Halfhead Farm, Shallowford, has joined the YEN. “We achieved 82kg/hl specific weight from Graham last year, and I’d like to understand why,” he says.

He managed to get 100kgN/ha of urea onto the later-drilled wheats – there’s 150ha of Graham, KWS Kerrin and KWS Silverstone on heavy clay. “It took a while to work, but the crop’s looking greener – the first dose is the best value for money,” he says.

James Mayes is one of seven Sentry farm managers in the YEN who have joined XFC for the first time this year. At Bentfield Bury Farm near Stansted Mountfitchet his 206ha of Lily, Skyfall and Zyatt on heavy boulder clay wasn’t drilled until Oct.

“Our first opportunity for N applications coincided with recent snow and rain events. Since then it’s stayed wet and made travelling impossible – we’re now keen to get on. One thing we’re learning through YEN is the importance of building biomass early on.”

There are plans among the XFC group to look in more detail at specific areas of crop management, including potentially running on-farm trials.

Andrew Pitts would like to predict milling wheat N requirement earlier. “I overcooked the N on Skyfall last year and ended up with 14-15% protein. I’d like to know how to refine the last dose better to the crop.”

Mark Means and Andrew Williamson are keen to look at the effect of putting SDHIs on at T2 and T3 timings, while for Russ it’s “maximising ear population and/or influencing grain numbers per ear. Is there a way to manipulate more and optimise what is produced?”

James and the other Sentry farmers are keen to look more closely at trace elements. “It will be interesting to assess the difference more regular tissue testing will make to our group in respect of our different geographical locations and varying soil types,” he says.

Partners in Performance

Partners in Performance is the result of a long-standing collaboration between Bayer and a group of progressive growers.

It started in 2011 with the launch of Aviator Xpro when growers were invited to trial Aviator on their farm. In these split-field trials Bayer took a back seat with the only demands being the field area for fungicide comparison and crop yield verified over a weighbridge or via combine yield monitor – everything else was down to the farmer.

Over time this developed into more of a club. Each year the farmers would meet to discuss results, listen to guest speakers and debate winter wheat management issues.

Farming has always been a challenging business, and with Brexit those challenges have intensified. The margin between profit and breaking even is likely to become even tighter and any incremental gain will be needed for sustainable combinable crop production.

To achieve that the industry needs to work together to share the latest research and thinking, exchange ideas and experiences.

To achieve that the industry needs to work together to share the latest research and thinking, exchange ideas and experiences.

Partners in Performance aims to bring farmers and specialists together to develop solutions to improve crop performance and investment return.