Agritechnica’a Innovation awards provide a pointer for where machinery innovation’s heading. CPM picks out some highlights.

Agritechnica’a Innovation awards provide a pointer for where machinery innovation’s heading. CPM picks out some highlights.

By David Jones

This year at Agritechnica, the independent committee appointed by the DLG (German Agricultural Society) had the task of choosing innovation medal winners from a total of 320 entries. German manufacturers dominated the stage – which won’t be seen as headline news, based on the competition’s history – but there were a number of ideas that’ll no doubt progress into widespread usage in their particular fields.

Gold – Cemos Automatic Threshing System (CATS)

Developed by Claas for use on its straw-walker and hybrid combines, this system seeks to help remove the onus of decision from operators regarding the optimum settings for drum speed, concave gap and the aggressiveness of threshing in order to achieve optimum grain quality in the prevailing harvest conditions.

Developed by Claas for use on its straw-walker and hybrid combines, this system seeks to help remove the onus of decision from operators regarding the optimum settings for drum speed, concave gap and the aggressiveness of threshing in order to achieve optimum grain quality in the prevailing harvest conditions.

By removing the decision-making role from the operator – as to what the optimum machine settings will be for the conditions – CATS is able to make the various adjustments to produce grain of a consistent quality standard.

Gold – Kemper StalkBuster

Developed jointly with John Deere, the StalkBuster is a response to the damage caused by the corn borer – the number one enemy of silage maize crops in Germany (and, potentially, following wheat crops). Comprehensive destruction of the maize stubble has been identified as one of the key actions in dealing with the pest: enter, the StalkBuster.

With stubble being the preferred over-wintering habitat of the corn borer, this machine forms an integral part of the maize header and destroys the remains of the crop before it can be driven over by the forager or tractor and trailer.

Silver – Fendt e100 Vario

While electrically powered cars have been around for a while, the technology has so far missed the commercial vehicle sector, due principally to the challenges of producing a sufficiently powerful battery for the heavy work involved. The e100 Vario uses a quick-charging 100kWh battery providing sufficient power for four hours’ work. A thermal management system includes a heat pump to control cab temperature and the battery can also be used as storage for farm-generated power.

Silver – Claas Axion 900 Terra Trac

This semi-tracked, fully suspended tractor is considered to provide both operator comfort at high transport speeds and greater protection of the soil’s structure. To achieve this, the 900 Terra Trac is the first semi-tracked tractor to provide a suspended front and rear axle – which also provides good directional stability in the field.

Silver – Camera-supported seedbed preparation

Introduced by Pӧttinger, but developed jointly with New Holland, this system involves the use of cameras that take real-time footage of the soil surface and the incidence and size of clods. The operator enters a target value and the actual ‘cloddiness’ is measured from the ground behind the power harrow.

The reading is transmitted to the job processor and, via the implement’s ECU, the system then automatically controls the tractor’s ground speed and the power harrow PTO speed to produce the desired level of top tilth. As a result, the system is able to create a uniform seedbed in a variety of soils.

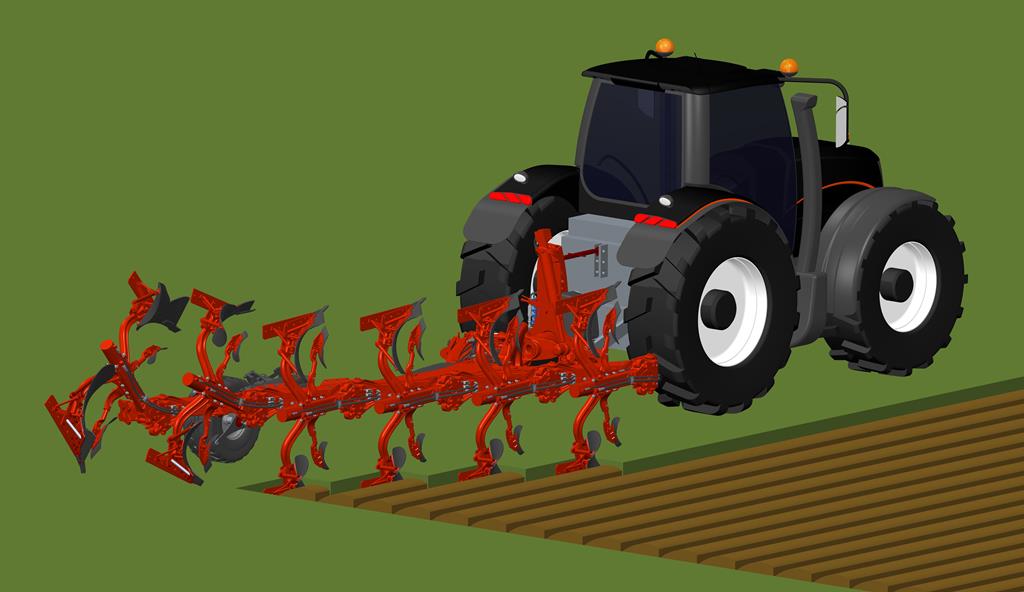

Silver – Kuhn automated plough lift-out

“An enormous plus for field hygiene” is how the company describes this GPS-based facility. Ever-wider working widths have caused Z-shaped patterns to be created at headlands when the implement is raised, which, in turn, means crop residues and volunteers aren’t properly incorporated.

“An enormous plus for field hygiene” is how the company describes this GPS-based facility. Ever-wider working widths have caused Z-shaped patterns to be created at headlands when the implement is raised, which, in turn, means crop residues and volunteers aren’t properly incorporated.

Kuhn has developed a hydraulic system that controls individual plough blades, raising and lowering them – based on GPS positioning data – to create a totally straight furrow edge where there used to be a ‘Z’. Subsequent tasks – headland ploughing, drilling, spreading and spraying, etc – are simplified and more effective.

Silver – AGCO Ideal combine harvesters

Massey Ferguson and Fendt have managed to overcome the dilemma between high capacity and transport width with a new range of high-capacity harvesters that have a maximum road width of 3.3m. With the entire machine having been developed from scratch, this has been achieved by restricting the threshing width. Automatic header attachment with header identification also make their market debuts.

Silver – Krone Forager LiftCab

Driving all day into a ‘wall’ of maize can now be relieved with the option of LiftCab, which raises the cab by up to 70cm to give the operator a clearer picture of work progress and the whereabouts of the harvest fleet, so reducing stress and fatigue. LiftCab also facilitates easier access to service and maintenance points.

Silver – Large Vehicle Alert System

Claas has made use of the capabilities of telematics to develop a system that warns other road users of the proximity of large machines, such as harvesters, on narrow roads. It provides the assistance systems of car and truck drivers in the locality with the machine’s location, so allowing alternative routes to be selected.