Though some may be sceptical about the benefits of using adjuvants, two growers are achieving great results by incorporating them into their spray programmes. CPM finds out more.

“All spray operators are trying to achieve the same thing, and that’s getting the best out of the products they apply.”

By Charlotte Cunningham

Despite sometimes being cast off as ‘muck and magic’, adjuvants can make for an incredibly beneficial partner in the crop protection programme.

When used correctly, the benefits can be meaningful, from reducing drift to minimising alkaline hydrolysis, as Wiltshire farm manager, Martin Smart, knows all too well.

Martin Smart (foreground) believes that a lack of understanding about how to use adjuvants is the cause of criticism about their effectiveness.

Overseeing the management of more than 1200ha of arable ground spread over a 15-mile radius as part of the Ashton Farms operations, Martin has a busy workload which is put under further pressure due to catchy weather patterns and challenging soil and spraying conditions. “Our average rainfall is about 750mm a year, but no two seasons are the same. We can go through spells where it’s really dry, and then all of a sudden it turns. We’re also quite often affected by strong south-westerly winds,” he explains.

“Our spray days are often limited, so when sprayers are running, we have to make the most of it and get the best out of the chemicals we’re using – which is getting more and more difficult every year. We’re also in a very hard water area which has a big impact on the efficacy of some of the chemistry we use too.”

With these challenges in mind, Martin began exploring how adjuvants might help alleviate some of the pressure points in the spraying operations. “I’m passionate about spraying and always looking to learn and improve on what we’re doing, so when an Agrii agronomist introduced us to Kantor, I was keen to know more.”

Kantor is an activator adjuvant from Interagro which is designed to enhance compatibility in tank mixes, control drift and improve both chemical penetration and retention. “It sounded impressive, so I tried it myself, doing trials with different types of jets. While the drift control was obvious immediately, what I was really impressed with is how much better the chemistry spread on the leaf – when you turned around at the end of the field you could see the leaf was really wet, as if you’d wiped it, rather than just sprayed it on in little droplets. I think that was the best coverage I’d achieved to date at that point.”

Following a successful first impression, Kantor has become an essential companion in the spray programme.

Kantor is a must-include in glyphosate mixes due to the antagonistic effect it can have on products), explains Martin. “ To tackle the hard water issues, we use a water conditioner and also use harvested rainwater where we can to minimise the impact on our chemistry.”

But the specialist adjuvant also has a more general purpose and is used any time Martin is concerned about drift or coverage being affected by the conditions, which has in turn improved the effectiveness of sprays at the key fungicide timing applications. “The majority of our applications now include Kantor. Getting the right product where it needs to be at the right time is so important.

“We’re losing products left, right and centre at an alarming rate and efficacy is breaking down a lot quicker than people realise, so anything we can do or use to help make the most of what we do have has got to be a good thing.

“We’ve all – as sprayer operators – got to be looking at what more we can do. It’s down to us to get products where they need to be and get as much out of them as we can. Good spraying is a bit like a good Formula 1 car – it’s not one thing that makes the big difference to performance, it’s all the little things.”

Steve May has been using adjuvants for a long time in a bid to improve the efficiency of his spraying by increasing uptake of chemicals on crops and weeds.

As the 2022 Spray Operator of the Year, getting the best from chemistry is a core part of Steve May’s ethos. Steve is the arable foreman at Northamptonshire-based Fromant and Sanders and oversees the management of over 800ha.

“We’ve been using adjuvants for a long time here,” explains Steve. “The advice initially came from our agronomist, on the back of trying to improve the efficiency of what we do by increasing uptake of chemicals on crops or weeds.”

Much like Martin, Steve’s arable ground includes hills which are susceptible to the effects of wind, as well as hard water which causes havoc with some tank mixes. “Essentially what we’re looking to do is minimise drift and prevent alkaline hydrolysis.”

To achieve this, Steve has also been using Kantor, as well as other adjuvants from the Interagro stable, including Backrow – a specialist activator adjuvant – and Toil, a methylated rapeseed adjuvant oil, to aid wild oat control. “Kantor is really easy to use. It mixes well, cleans out the can easily and does what it says it will.”

Use is selective and based on a decision around the chemistry being used, temperature and weather conditions at the time of spraying, he explains. “Glyphosate is the obvious one where we’d look to use an adjuvant, as well as with some of the fungicides in the spring and with plant growth regulators.”

The benefits are meaningful, but Steve says something he always visibly notices is drift reduction. “It’s sometimes hard to see with your eye exactly how much you’re improving your chemistry, but you can definitely see an immediate noticeable reduction in drift with Kantor.

“Sometimes we’re quite pushed into spots we don’t really want to go into with the wind, so if you can put something in the tank just to help you out, it can make quite a big difference.”

Adjuvants and water conditioners were the topic of a recent NRoSO course attended by Martin and he says he was left ‘shocked’ at the attitude towards the products. “The course leader asked if anyone in the room used them regularly, so I put my hand up and there were murmurs around the room to the tune of ‘what a load of rubbish’.

“Lots of people still seem to think they don’t work and are just a bit of ‘muck and magic’, but in my opinion I think that’s down to a lack of understanding about what adjuvants are for, the different types of adjuvants and where you’d use each one,” he believes.

“Ultimately, all spray operators are trying to achieve the same thing, and that’s getting the best out of the products they apply. So while I know there are adjuvants out there which might not work as well as others, for me Kantor really works and does exactly what it says on the tin.”

Good knowledge of the adjuvant being used is key to getting the most out of them, believes Stuart Sutherland.

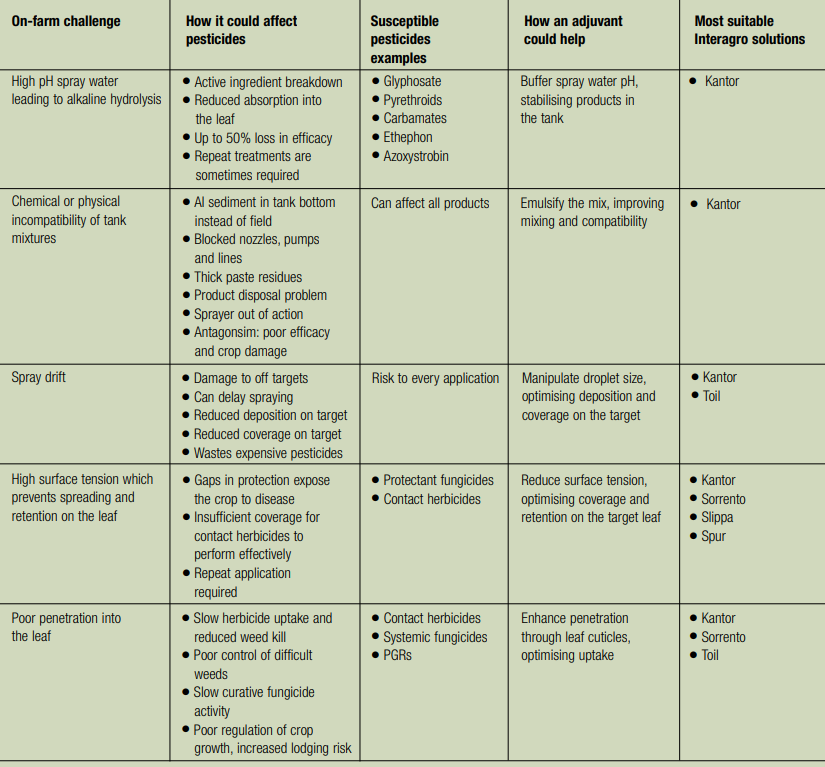

Stuart Sutherland, technical manager at Interagro, agrees and says that using the wrong adjuvant at the wrong time is often the reason why many growers are left scratching their heads when it comes to their effectiveness. “As a general explanation, adjuvants are designed to fulfil a variety of functions – from stabilising tank mixes to improving application. When used correctly, they can enhance biological efficacy and improve crop safety by modifying the physical characteristics of the spray solution to overcome the obstacles that may compromise performance.”

Adjuvants fall in to two different categories – activator adjuvants and special purpose adjuvants – and knowing the difference between the two is vital for deciding if and when they might be appropriate, explains Stuart.

“Activator adjuvants include surfactants, non-ionic and methylated seed oils, which are all designed to improve pesticide coverage and penetration. This is in comparison with special purpose adjuvants, which include buffering, compatibility and anti-drift agents. These types of adjuvants are targeted more at stabilising tank mixes and pH levels, as well as controlling drift, so it’s important to choose the most appropriate adjuvant for the job to optimise performance.”

However, Kantor combines the best of both, offering growers a ‘one-can’ solution, believes Stuart. “Kantor can be used on a wide range of crops, from the typical combinables like oilseed rape to other crops including potatoes, linseed and vining peas.

“The key functions of Kantor are to improve tank-mixing via a micro-emulsifying compatibility aid and reduce pH, as well as to boost spreading and retention by reducing surface tension between the spray solution and the crop surface,” he explains. “Drift control is possible due to Kantor’s ability to reduce the number of ultra-fine spray droplets and instead maintain a more uniform droplet size which is key for optimum coverage and retention.”

To back the performance claims up, Kantor has been tested in various trials. This includes a 2018 study at Silsoe Spray Applications Unit which looked at the effect of Kantor on droplet size and spray angle uniformity.

The performance of the fungicide Kestrel (prothioconazole+ tebuconazole) alone was compared with the performance of Kestrel plus Kantor – a volume of 0.15% – when put through a Lurmark 03F110 flat fan nozzle at a water volume of 200 l/ha. “In this study, Kantor was proven to significantly reduce the number of drift-prone Kestrel droplets and increased spray angle uniformity at the nozzle,” explains Stuart.

So when it comes to selecting the right adjuvant for the job in hand, where’s the best place to start? Stuart recommends taking a look at the pesticide label as the first port of call. “Advice may be given that must be followed regarding what type of adjuvant to use/avoid.”

He says it’s also important to select products from a trusted manufacturer, which has data to back up the claims of its products. “While adjuvant manufacturers may offer products with many of the same functions, product quality and adjuvant technology vary dramatically.

“It’s also important to remember that using an adjuvant is not always necessary. Think about your target, the pesticides you’re applying and what they need to do. In good conditions, you may not need one and you might therefore not see a benefit. On the other hand, there may be weaknesses in your spray preparation, application and delivery that can be improved,” says Stuart.

“Finally, keep it mind that although different adjuvants can perform a variety of different functions and significantly improve pesticide performance, no one adjuvant can perform every function for every situation. Make sure you have a good knowledge of the adjuvant you are using and that it’s the right one for the job.”

Adjuvants overview – why, when and what to use

[Source: Interagro]

Pushing performance

At the heart of good crop production lies careful use of chemistry to protect the plant and maintain performance, right through the season. But optimising the efficacy of plant protection products can be challenging, while increasingly restrictive regulations limit just how far you can go.

This series of articles explores the science behind the use of adjuvant and biostimulant tools to help power both chemistry and crop performance, as well as increase understanding of why they’re needed and what they do. We’re setting out to empower growers and drive crops to reach their full potential.

Kantor is the unique one-can adjuvant solution that brings unbeatable performance to crop protection sprays by overcoming the physical and chemical barriers that compromise optimal targeting and delivery. Bringing durability to tank mixes, reliability in suboptimal application conditions, and versatility in use, Kantor is the perfect partner for dependable herbicide, fungicide and PGR performance all season long.

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.