Could applying molybdenum as a spring fertiliser coating fire up nitrogen conversion and play a key role in improving nitrogen use efficiency? CPM digs a little deeper to find out.

Molybdenum applied as a coating on nitrogen fertiliser has the greatest impact as it feeds both the crop and the soil bacteria.

By Lucy de la Pasture

Improving nitrogen use efficiency (NUE) has become the Holy Grail in arable circles recently, with growers focusing on small gains to improve the plant’s access to any fertiliser that’s applied.

By firing up nitrification, with molybdenum as the main catalyst, it increases the ease with which plant roots can access and consume nitrogen from the soil, says Peter Scott.

NUE is well recognised in academic circles and has gained profile through the work and publications of the EU Nitrogen Expert Panel, explains Jane Salter, head of environmental policy at AIC. The body brought together policymakers, industry and scientists to rigorously test its application as a policy driver and for its practicality on farm. She believes improving NUE has significant importance to agriculture now and in the future.

“There are no downsides to NUE – the farmer gets more crop per kg of N, the environment benefits from less available N being potentially lost as ammonia, nitrous oxide and nitrate, and there’s a political win all round for achieving it.

“I can’t overemphasise the importance of nutrient management as part of the National Food Strategy and new environmental targets currently being consulted on. The next 10 years are crucial; our cropping systems must be more resilient to meet net zero, water, soil and air quality commitments made in the 25-year Environment Plan.

“We can’t lobby the environmental pressures away; farming and the environment are inseparable and finding solutions that work for both must be the way ahead,” she believes.

There are many factors which influence NUE in crops and the interaction molybdenum has with nitrogen shouldn’t be underestimated, believes Peter Scott, technical director at Origin Fertilisers. He highlights the outcome of two recent trials that have shown significant gains in both crop yield and NUE by applying molybdenum as a coating to nitrogen fertiliser in spring.

The trials took place in crops of spring barley and winter wheat during 2021 and highlight the relevance of knowing the properties of individual micronutrients to improve the use of nitrogen, believes Peter. He says that although molybdenum is used in the plant to break down nitrogen, it has an essential role in soil biology too.

“Micronutrients have different properties and react with nitrogen in a variety of ways. We know that molybdenum is key to nitrogen uptake, but we wanted to find out if it would have a greater or lesser effect on the plant’s ability to use nitrogen by applying it to the fertiliser granule. We also wanted to find out whether more nitrogen would be available in the soil.”

The spring barley variety under the microscope was Laureate in a trial which took place in Angus, Scotland. The Origin molybdenum coating on both the seedbed and top-dressing fertilisers was compared with a seedbed NPKS application and nitrogen/sulphur top dressing.

“The key findings were a yield increase of 3.5% over the standard application and an increase in NUE of 8.9%. Of equal interest is a return on investment of 6:1, meaning the coated fertiliser application had a positive impact on the bottom line,” explains Peter.

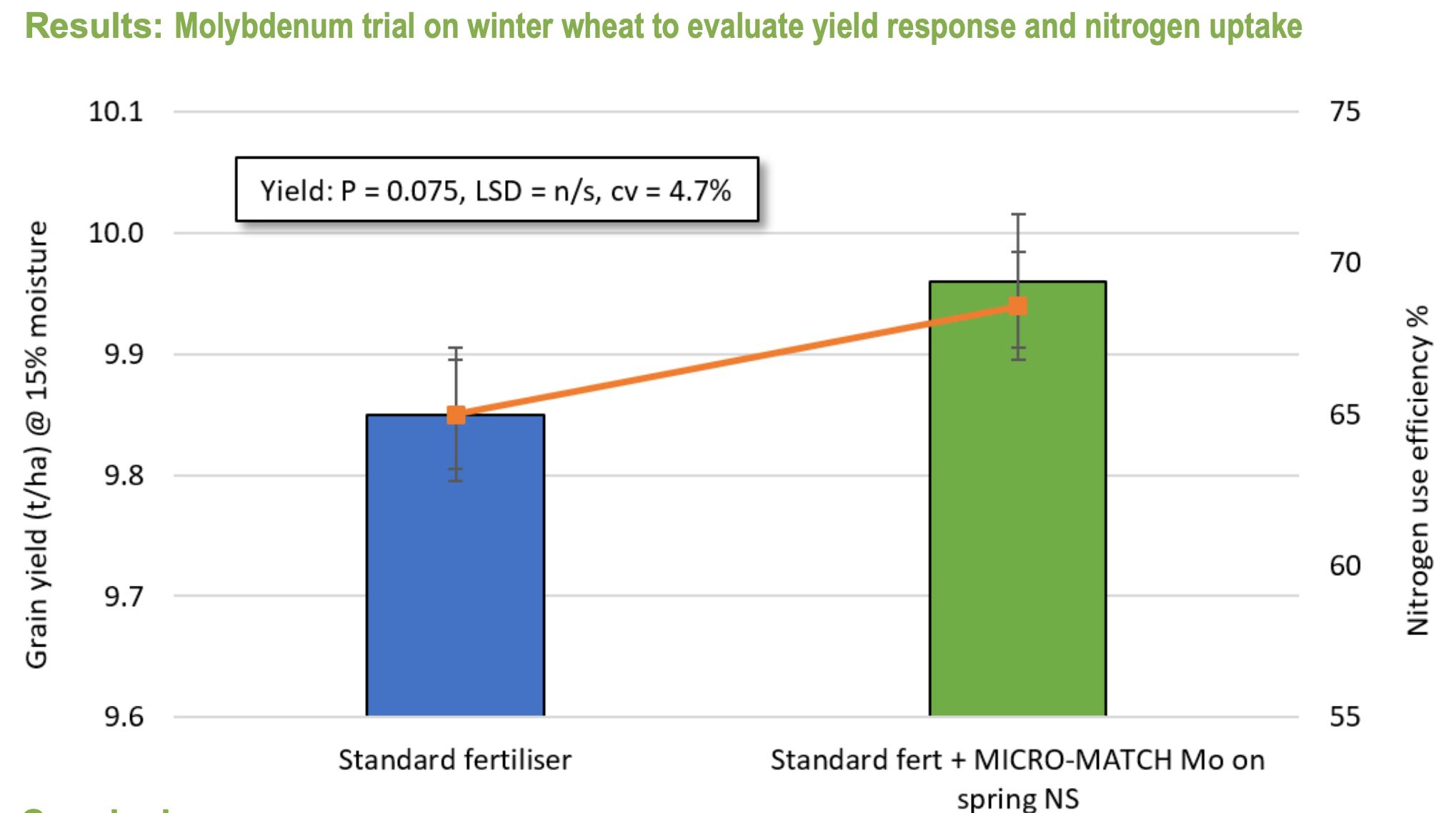

“It was a similar story in the winter wheat trial carried out in Yorkshire. An increase of 5.4% in NUE was achieved, along with a 1.1% uplift in yield, and the treatment offered a 2:1 return on investment.

“The gains in yield and NUE will be welcomed by farmers keen to understand how micronutrients play an integral role to soil and plant biology,” believes Peter.

The trials began with a broad-spectrum soil analysis of the field, which highlighted low molybdenum levels and a pH of 6.8 across the clay loam soil. The trials also highlight that how molybdenum is applied affects its efficiency as a catalyst for the nitrogen, he explains.

Source: Origin Fertilisers, 2021

“The availability of most micronutrients increases as soils become more acidic, having a lower pH. For molybdenum, the opposite is true and availability will increase when soil pH is higher. So growers with a soil deficient in molybdenum should be evaluating the best way to get molybdenum to where it’s required,” he suggests.

“Micronutrients are usually applied as a foliar application. However, these results highlight molybdenum applied as a coating on nitrogen fertiliser has the greatest impact as it feeds both the crop and the soil bacteria that require molybdenum as a catalyst to function.”

This insight was gleaned from a tailored application of Origin Fertilisers’ NUE-Trition range, which use micronutrient coatings, such as molybdenum, on fertiliser. Even if the soil is showing as not deficient, Peter is of the view that farmers could be applying this key nutrient to improve the sustainability of nitrogen – helping the crop take up more of it rather than losing N to the environment through nitrate leaching, denitrification, or ammonia volatilisation.

“The Origin molybdenum coating is applied to the granules in the form of a dry powder that has an electrostatic charge and doesn’t require a liquid to attach it to the fertiliser. The dry powder acts like a magnet and disperses evenly across the granule,” he explains.

“Recognising a soil is deficient in certain nutrients allows a detailed and prescriptive fertiliser application to be tailored to correct these issues, and a micronutrient coating on a fertiliser granule enables it to start working as soon as the nitrogen begins to dissolve.”

Jane agrees and says that understanding the key drivers for improving NUE starts with soil health and a good nutrient balance.

Jane Salter comments there are no downsides to NUE – more crop per kg of N, the environment benefits, and there’s a political win all round for achieving it. ©Tim Scrivener Photographer 07850 303986

….Covering Agriculture In The UK….

She advocates for farmers to better understand NUE and the factors influencing it, with the support of their FACTS qualified advisers. She suggests it’s measured on farms and crop level targets set for percent improvements over time.

“It’s also looking probable that future farm payments will incentivise our joint commitment to driving NUE, which indicates government and wider stakeholder support now,” she comments.

But to achieve a better understanding of NUE, it’s necessary to understand how improvements can be made. Peter explains the science behind the part molybdenum plays in improving NUE, saying that as a naturally occurring metal, its presence in the soil aids the conversion of nitrogen from ammonium to nitrates.

“But we should think of molybdenum’s interaction with nitrogen in two parts,” he adds. “Molybdenum is the catalyst required for the conversion of nitrogen and is essential for soil biology. It sparks a reaction in soil bacteria enzymes that stimulate the nitrification process. The second part of molybdenum’s role is the conversion in the plant of raw nitrogen into protein.

“In the soil, nitrogen starts off as ammonium, and during nitrification it loses hydrogen and gains oxygen, changing it from ammonium into nitrite and then nitrate. By firing up nitrification, with molybdenum as the main catalyst, we’re increasing the ease with which plant roots can access and consume nitrogen from the soil.”

Molybdenum’s presence is also helping legumes, such as peas and beans, fix nitrogen which can give a wider appreciation of its importance when looking at NUE enhancers.

“Legumes are well known for their ability to fix atmospheric nitrogen using nodules that form on the roots of the plant, and the metal catalyst needed for this is molybdenum. It acts as a metallo-catalyst to fix nitrogen from the atmosphere and lock it into the nodules.”

It’s a key component in the soil, but plants will only be able to take up so much nitrogen before they reach capacity. Plants need to be able to convert this nitrogen into protein through an enzyme called nitrate reductase, and an essential catalyst for this process is molybdenum, explains Peter.

“A shortage of nitrate reductase in the plant will cause it to slow down its nitrogen uptake. In a similar way to when we are full, we need time to convert the food into energy, the plant requires molybdenum to convert nitrogen into protein, and therefore allow room for more nitrogen to be taken up. This process is called nitrogen assimilation.

“By choosing to apply molybdenum as a foliar application, it could mean that levels in the soil are low, and it means the plant has to work harder to access nitrogen, therefore reducing the efficiency with which nitrogen is converted.”

Due to its close relationship with nitrogen, a soil deficient in molybdenum can lead to the plant showing the same symptoms as one with nitrogen deficiency. Molybdenum is mobile within the plant, which means older leaves are affected first with a pale, yellowing of the smaller leaves.

Soil type also plays a part – sandy soils with low cation exchange capacity (CEC) are likely to have low molybdenum holding capacity. Conversely, soils with good organic matter content will hold onto molybdenum well, he adds.

This article was taken from the latest issue of CPM. For more articles like this, subscribe here.