Growers have been urged not to neglect the pH status of their soils in a bid to cut costs. Early autumn is the ideal time for spreading lime and current dry conditions mean spreaders can travel with minimal damage to soils.

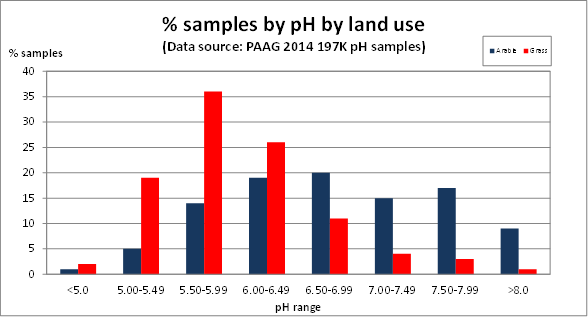

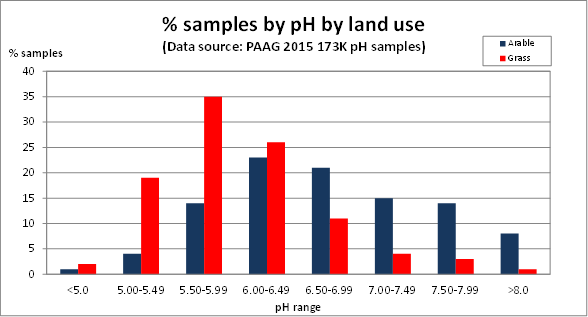

Figures from the Professional Agricultural Analysis Group (PAAG) of routine soil analysis suggest the pH status of arable soils may be dropping.

In 2014, the proportion of arable soil samples found below the target pH6.5 – the level at which the availability of most nutrients is optimised – was 39%. But this rose last year to 42% (see charts below).

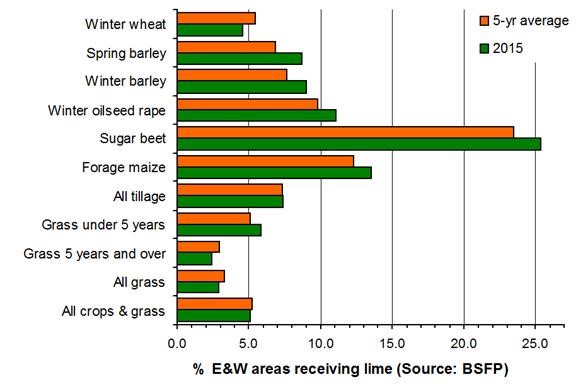

The current status of grassland is worse, with PAAG figures showing more than four out of five samples tested fall below pH6.5. British Survey of Fertiliser Practice (BSFP) data show just 7% of arable and less than 3% of grassland receives lime, however.

Fundamental requirement

Fundamental requirement

Maintaining mineral arable soils at pH 6.5 is a fundamental requirement for a productive crop, points out Edward Downing, crop nutrition technical manager with Frontier.

“Growers may be looking to save money, but it’s hard to cover crop input costs with a low yield,” he says.

“That means getting the basics right before you can start to move forward, and when it comes to efficient use of nutrition, you can’t even pass Go until you sort out your lime status.”

Maintaining the correct pH should be considered a key part of nutrient management planning, adds ADAS soil scientist Dr Lizzie Sagoo. “If the soil pH is too low then the nutrient use efficiency of applied fertilisers will be reduced,” she explains.

Maintaining the correct pH should be considered a key part of nutrient management planning, says Lizzie Sagoo.

“Growers should take soil samples for routine soil analysis, including pH, every 3-5 years. Soil pH can vary within fields and in some cases it’s worth more intensive GPS soil sampling for pH.”

This includes areas within fields where there’s a known variation in soil type or texture. “This helps growers identify any areas of the field which are well below target pH.”

Some sampling services provide growers with detailed in-field measurement of soil pH, she notes. “The Veris MSP3 machine now includes measurement of soil pH, allowing growers to get a much more detailed picture of the variation in soil pH across the field.”

Sampling services

More commonly, sampling services will map fields on a zonal or grid basis and provide information growers can pass on to spreading contactors.

This is the basis of Agrovista’s Precision Services, for example. While Frontier provides sampling and precision-mapping services for pH and all major crop nutrients through Soyl.

Soilquest from Agrii provides three levels of sampling services says the firm’s Stuart Alexander. “This ranges from a whole field offer which includes one representative sample per field, while Soil Reflection is based on management zones created from satellite imagery.”

Soil Scan is its sampling service based on management zones that can be determined through an electrical conductivity (EC) scan.

Not every grower wishes to go to the expense or has the need for an EC Scan, points out Oliver Wood of Hutchinsons’ Omnia Precision Agronomy.

Usually around 20 separate samples are taken to represent each zone.

“Our normal procedure is zonal sampling, but we’d sit down with the grower to determine the zones, based on what information they have to hand. This may be yield maps, an EC scan, or simply years of knowledge and experience.”

When it comes to application, lime recommendations given in RB209 are based on ground limestone or ground chalk with a neutralising value (NV) of 50-55%, points out Lizzie Sagoo.

“If you’re using another type of liming material, you need to work out the application rate, taking into account the NV,” she says.

So if the lime recommendation in RB209 is 6t/ha of ground lime or chalk and the material being used is paper sludge ash with an NV of 37, the amount required is (50/37) x 6 = 8.1t/ha.

Fine material

Another important quality to take into consideration is how fine the material is, points out Richard Cogman, National Limex manager for British Sugar.

“A fine material will react quickly in the soil and return it to a healthy pH ready for the next crop. If it’s too coarse this may take some time, or not at all in extreme cases of poor quality.”

Most agricultural lime should be fine enough such that 40% of it will pass through a 150-micron sieve, he says. “The standard for our Limex 70, a dry, friable material, or Limex 45, a damper product spread via manure spreader with spinning discs, is more than 85%. But we have come across other material on farm recently that’s as low as 4%.”

Growers should also consider additional nutrient value, he adds, with Limex 70 adding significant amounts of phosphate, sulphate and magnesium. “At a typical spreading rate of 7.5t/ha, this can be worth £60/ha,” he points out.

Another option is granular material, such as Calcifert and Calciprill, notes Edward Downing. “You can spread it with your own on-farm spreader, but the granules are formed from finely ground, high purity calcium carbonate.”

This means a considerably lower use rate is needed, and it’s used in a different way, he explains. “It has a reputation as a fire-brigade treatment as you can apply it to the standing crop using the tramlines, but it’s best used across the rotation, applying every two years to keep the pH closer to the optimum.”

The best time to apply bulk lime is after crop’s cut in dry conditions.

The best time to apply bulk lime is after crop’s cut in dry conditions, although it can be applied at any time of the year, notes Sheila Johnson of Norfolk-based GJ Orford Partners.

The firm runs five different spreading machines across Norfolk, Suffolk, parts of Cambs, Lincs and Essex, including one on row-crop wheels, suitable for use in horticultural situations, for example, in the standing crop.

“Most commonly, though, we’ll apply to the stubble using a three-wheel Terra-Gator. This spreads up to 10t/ha to 12m and the wheel configuration spreads the weight well.”

It’s an operation that typically takes place when growers are at their busiest, she notes, so good communication beforehand helps to ensure a smooth operation with minimal disruption.

“What makes the biggest difference is where we have good maps. These should show which fields are receiving lime at what rate, the access from the road and where the material should be tipped – the more detailed, the better.”

Most lime is spread at a fixed rate, although operators can apply just to parts of fields, or apply different rates within fields.

“We have one machine that can apply the material variably, using a GPS controller, for those who require that service,” adds Sheila Johnson.