This season burning-off will be a step into the unknown for many. CPM discovers how decisions made before a tuber is even planted will influence the success of desiccation at the tail end of the season.

Nitrogen management will be especially important on indeterminate varieties.

By Lucy de la Pasture and Rob Jones

If there’s one thing potato growers are very good at then it’s adjusting to change. The past few years has seen the loss of many pesticide stalwarts and this year is no exception, with perhaps two of the most relied upon, diquat and CIPC, no longer approved for use.

The potato industry has lost its major desiccant before, when sulphuric acid was withdrawn in 2009. Back then diquat was there to take up the slack and desiccation was still achievable with a split application. This time around the two remaining desiccants – Gozai (pyraflufen-ethyl) and Spotlight (carfentrazone-ethyl) – are known to be most effective on stems, leading many growers down the road of flailing the crop as a first step to remove the foliage.

Other growers, who are either unwilling or unable to flail due to soil type considerations, are also facing a more protracted period of desiccation with three or four applications of desiccant required.

Whichever system is being adopted, preparing for the change starts before the crop is planted. AHDB’s Dr Bill Watts suggests growers make sure they understand their biggest challenges – from varietal determinacy and nitrogen management to expected time of harvest.

“Where growers are planting indeterminate varieties which have a high haulm longevity – such as Markies and Royal – planting early can bring forward the desiccation timing whilst maintaining yield. But in areas prone to late frosts, such as the Fens, moving planting forwards isn’t always an option.

“Nitrogen management will be especially important on indeterminate varieties. Growers should supply enough nitrogen for yield, but also aim to produce crops that are near to natural senescence at the point of T1 desiccation.” he says.

Bill suggests growers think backwards from the time they intend to desiccate to help plan the nitrogen requirement to be ‘just enough’ rather than too much.

Will Gagg, manager of AHDB’s strategic potato (SPot) farm in the North, says he’s been cutting back on the amount of nitrogen applied to crops in general in response to the long-term work being carried out by Dr Mark Stalham of NIAB CUF. His research has shown that, on average, growers are applying an excess of about 30kgN/ha to their potato crops.

Without diquat, Will really appreciates the need to avoid producing excess canopy. “On some varieties I plan to cut right back on nitrogen so that we can kill the plant more easily. But I’m not overly worried as I think the flail we’ve invested in will cope, however if we were going solely down the chemical route to desiccate it’s something I’d look at even more closely,” he says.

The potato market has been notoriously slow to change when it comes to varieties, so growers may be largely constrained when it comes to making varietal choices. But where farms are equipped to chit seed then this could be another tool to help bring harvest forward, says David.

“By chitting seed, growers can physiologically age seed tubers which will result in a shorter growing period in the ground, hence earlier onset of senescence,” he comments.

All the possible combinations and sequences of desiccation chemistry and machines have been trialled at the AHDB’s regional SPot farms, as well as at other trials programmes throughout the country. AHDB’s David Wilson says the results have been ‘better than expected’ which has helped alleviate some of the worry about making changes to desiccation practice, though he points out that 2019 was a kind season.

When it comes to applying chemical desiccants, the AHDB trials have highlighted that application mid-late morning has a better effect than in late-afternoon.

“There were big differences in defoliation in the treatments we looked at, but this didn’t correspond with the time to skin set and there were no statistical differences between any of the treatments trialled.

But what is clear from the work done last season is that there’s green leaf in the crop for longer, which will have a number of consequences,” explains David.

“Achieving burn down is going to take at least a week longer than with diquat, so blight programmes will need to cover this. It will be important to plan blight sprays so that chemistry with activity on tuber blight is still legally available to put on at the tail-end of the season,” he says.

Bill adds that growers have achieved highly effective desiccation in the South West using water volumes of 400 l/ha to improve coverage, but that care should be taken to avoid dilution of tank- mixed blight protectants.

“The slower speed of foliar desiccation achieved using the diquat alternatives means maintaining a robust blight programme is going to be important for some time after a T1 desiccation treatment. Even so, the speed of skin set seems to be comparable with diquat and no extra bulking of tubers has been seen in AHDB field work,” he adds.

There may even be a silver lining to the demise of diquat, believes David. “Diquat was often applied with residual herbicides and the cut-off timing was up to 40% of the crop emerged in maincrop potatoes. This would sometimes result in the crop being knocked back at the beginning of the season, pushing maturity back. For Gozai and Spotlight, the cut off is much earlier,

at just 10% crop emergence in second earlies and maincrop, which will potentially result in less set-backs if used within the label restrictions.”

Many growers will opt for a flail to remove foliage as the first step in the desiccation process, believes David. But there are a number of things to bear in mind when moving to a flail system.

AHDB’s Harry Henderson points out that an easy mistake to make would be to forget to check bed formation against flail set up. “Destoners and planters operate on a single bed, but flails may operate over two or three beds, so it’s going to be really important to match the topper to the rows – just a few centimetres out will make a big difference,” he says.

It’s a trap Will is making sure he doesn’t fall into. “We were very conscious how we set out the beds and rows when we looked at buying a flail topper. On our Wold soils we opt for a 80cm (32”) row on a 180cm (72”) bed, whereas on the silt soils we move to a 90cm (36”) row on a 180cm bed. We’ve had to buy a topper that can accommodate both row types,” he says.

Will also points out that they’re having to make changes to their headland breaks so that there’s enough room to turn with the flail. “We’re going to leave a much wider break of 5-6m so that we can get the flail in and out easier.”

One of the worries about relying on a flailing system is the effect a wet season would have on harvesting, he points out. “We’re going to have to increase our ability to grade and harvest in better format as I can see costs increasing by 12-16% depending on the conditions at flailing.”

Weighing up potato desiccation options without diquat

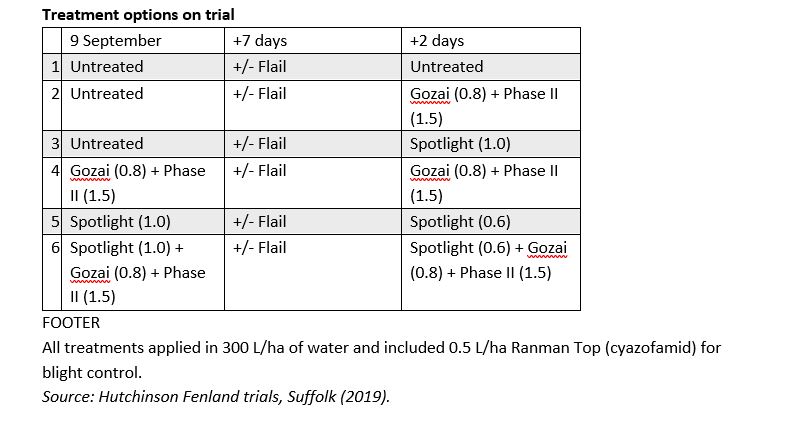

Various desiccation strategies were put to the test at Hutchinsons Fenland trials site, situated at A L Lee Farming Company’s Friesland Farm, near Mildenhall in Suffolk last September.

The work focussed on different timings and sequences of the two main chemical alternatives, Spotlight and Gozai, with and without flailing (see table 1) in an 18ha field of Markies on black fen soil.

Results across all treatments were better than expected, but agronomist Andrew Cromie stresses this was mainly due to conditions favouring desiccation. “Unusually, canopies were already starting to senesce by Sept, while warm, dry weather was ideal for chemistry to work quickly.

“We saw 85% burn-down within a week, which is extremely quick, and I doubt it would be repeated in another year with a big, growing canopy.”

Generally, the most effective strategy was to apply a desiccant to open up the canopy and follow this with mechanical topping. Andrew acknowledges flailing has challenges, especially in wetter years than the one just gone. Wheeling damage, erosion of potato beds, soil compaction and the potential for surface crop residues to increase disease risk in tubers must all be considered, as does weed pressure.

“Fortunately this Sept was very dry and our trial was in a very clean field, but if bindweed is present, flailing’s not an option,” he says.

Topping can also trigger regrowth from the plant’s axil, so growers should leave a reasonable amount of stem (at least 15-20cm) exposed and not covered with mulch, to ensure any follow-up herbicide can work effectively.

Results from plots where flailing wasn’t used suggest good canopy destruction and skin set can still be achieved through chemical applications alone, although the situation could be very different in other seasons and soil types, he warns.

The ‘belt and braces’ treatment (number six) shows the maximum that can be legally applied and performed best overall, but at a cost, Andrew points out. At £160-170/ha, that approach is double what might have been spent using a diquat-based programme.

John Keer from Richard Austin Agriculture says the number of treatments applied is as important as the products used, so the key is to start desiccation programmes earlier and knock-down canopies in stages.

“Sprays only kill the part of the plant they hit. Use the first application to open up the canopy, then alter subsequent applications according to the amount of green material left in the crop. Include a fungicide wherever you’ve still got green material to reduce the risk of late blight coming in,” he says.

Without flailing, three or four herbicide applications may be needed to achieve full desiccation, although it depends on the variety, soil type and weather, so decisions must be on a field-by-field and season-by-season basis, he says.

Regardless of the approach taken, desiccation is likely to take one to two weeks longer than with a diquat-based programme, so more focus is also needed on other ways of managing canopies to help speed-up the process, adds Andrew.

Planning starts before the crop is sown, with variety choice and soil type being key considerations. Growers may question whether growing a long-season variety like Markies is the right option on certain fields. In some cases, it may be better to go for a more determinate type that senesces earlier. Reducing nitrogen applications to avoid over-large canopies will also be worth considering.

Other novel desiccation options trialled at Friesland Farm included pelargonic acid, which is currently only available for amenity use in the UK, so pricing is prohibitive for agriculture (cost £250-500/ha at the 50-100 l/ha rates). Salt solution was also investigated (sodium/ potassium chloride) and was found to be slower acting than diquat and not as effective as herbicides. It also requires high water volumes, which adds logistical challenges.

The most challenging year yet?

Agrovista agronomist Jack Hoyles advises on 800ha of potatoes covering South Lincolnshire, Cambridgeshire and Norfolk, most of which is destined for the processing and pre-packed markets. He predicts that desiccation will pose the greatest single question for growers during 2020, with all viable options for destroying potato haulm presenting potential challenges for many growers.

“2020 could be the toughest year yet. Ensuring customers still achieve industry targets, such as market size, market dry matter and fry colour, with an ever-decreasing number of chemicals will require significant agronomic changes to the way we currently manage the crop, taking advanced planning to the next level,” he says.

During the 2019 season, many growers understandably still used diquat as part of their desiccation strategy, but new trials confirmed that both a ‘flail and spray’ and chemical-only approach to burning down the crop are both viable with advanced planning on canopy management.

“Desiccation (with and without flailing) is viable as long as you can control canopy growth and I achieved excellent results last year using the two stem desiccants; Gozai and Spotlight, as part of a three-four spray program designed to achieve full desiccation. As Gozai has a 14-day harvest interval it will be my first spray within the program sequence,” he comments.

It’s generally accepted growers will have to look at varieties carefully, particularly if considering reducing nitrogen rates to manipulate canopy growth in order to senesce the crop earlier. And it’s here that Jack sees some potential hurdles.

“Employing a fertiliser strategy on long season varieties such as Markies (a variety that many of my chippers grow) could be problematic. Markies have 12-20 tubers per plant, so if you cut back too heavily on fertiliser to control growth and then there’s a dry spell in spring you run the risk of not achieving market size by focusing too much on canopy size.

“Variety selection is critical but getting some luck with some warm dry summer weather to help senesce the crop naturally before harvest cannot be underestimated either,” he adds.

For early season weed control Jack believes filling the gap left by diquat should be far more straightforward given the chemical options available to growers.

“This year I’ll be basing my early season weed control around Soleto (metobromuron), which is my ‘go to’ residual herbicide. It’s safe on all varieties and on all soil types, so it takes all the guesswork out of the equation.

“With diquat no longer an option, I’ll be partnering Soleto with Gozai as my key contact herbicide – applying it at 0.4 l/ha, either on its own four-five days before the crop emerges or as part of a tank-mix.

“Good application timing and keeping water volumes up to ensure good coverage are the keys. To achieve best results I recommend using 200 l/ha of water and add a methylated seed oil when Gozai is applied alone and weeds are larger than four true leaves.