For the past three years, Suffolk grower Brian Barker hasn’t just been gleaning Real Results from his farmer-led field trials, but gathering data on how growers can be rewarded for the public goods they provide. CPM visits to find out.

What we want to achieve is a framework other farmers can follow and provide a wealth of data to back up a compelling case.

By Tom Allen-Stevens

Visit Suffolk grower Brian Barker between the months of October and April and you may well find him in a ditch at the edge of one of his fields, rather than monitoring the crop within it.

That’s because Brian believes it’s just as important to assess carefully what comes off the land as it is to put considered thought into what goes onto it, and he’s keen more science is applied to both.

Brian Barker has been taking regular samples throughout the winter from his field drains to measure the nitrate run-off from different crop covers.

“The aim is to demonstrate the public good of how we can manage the land. Doing so in one field on one farm won’t make a difference, but what we want to achieve is a framework other farmers can follow and provide a wealth of data to back up a compelling case,” he says.

Now he has the opportunity. Since 2017, EJ Barker and Sons, based at Lodge Farm, near Stowmarket, has hosted AHDB’s first strategic cereal farm, aiming to provide an independent, open and honest platform for UK farmers to see and learn from the integration of research in a practical way within a commercial farming system. It’s against this background that, for the same period, he’s been one of the 50 BASF Real Results farmers, and last year put the company’s new triazole in Revystar XE under the same scientific scrutiny.

“Working closely with AHDB, you get to understand the importance of statistical significance – it’s so important to compare like with like when it comes to on-farm trials. I like Real Results because it takes you out of your comfort zone, encouraging you to try something new. But underpinned with ADAS’ Agronomics, you know that the results you get back will stack up.”

The strategic farm involvement started after Brian finished his spell as an AHDB monitor farmer in 2017. “What I enjoyed most was the group of local farmers we’d built up around it. We were always asking questions about how we could improve our cropping systems, trialling things out on farm and sharing the results – I didn’t want to lose that.”

At the same time, AHDB was looking to grow its Farm Excellence Platform and build on the success it had in other sectors with networks such as the strategic potato (SPot) farms. Twinned with Brian’s enthusiasm, this paved the way for a six-year initiative that was launched in Nov 2017. The strategic cereal farm west has followed, hosted by Rob Fox at Squab Hall Farm, Warwicks, and a further farm is due to be launched later this year.

“For me it’s not just about field and farm-scale trials,” notes Brian. “We’re getting people onto the farm who wouldn’t ordinarily visit, such as those in the research community and policy-makers. It’s also about steering the juggernaut of AHDB R&D into a more practical, applied direction that connects better with farmers.”

Close involvement with local farmers through discussion days and on-farm events shape the priorities for the work carried out, generally done as a “look-see” in year one. Depending on results, a more detailed study may then follow, with a trials programme, normally including replicates, drawn up with research scientists.

Brian points out that what comes out of field drains is of huge public interest. “It costs £92M/year to remove pesticides from drinking water. Soil erosion and sedimentation costs £305M/year while removal of nitrates costs £170M/year. So there’d be a huge public benefit if farmers can develop solutions that keep inputs and soil in the field.”

Brian’s hunch was that cover crops would make a difference, so the look-see involved taking regular samples, 86 in total, throughout the winter from his field drains. There were nine separate sample points representing seven fields under different management – winter cereals, over-winter ploughed, grass and cover crop. He teamed up with Essex and Suffolk Water who tested the samples, focusing on nitrates.

“The EU Water Directive limit for nitrates is 50mg/l. What we found was that the over-winter ploughed land put double that limit through the drains, while the cover crop resulted in just 5mg/l of NO₃ lost from the field. It doesn’t take a scientist to tell you there’s a correlation there.”

With help from ADAS, trials were set up the following year as part of AHDB’s four-year Maxi Cover Crop project. This focused on two fields – one in stubble, the other ploughed – with half of each sown to a cover crop mix. A whole host of assessments were made, including NDVI scans, soil visual assessments and earthworm counts, alongside the nitrate offtakes.

“The over-winter bare ploughed land was worst, with average NO₃ concentration of 275mg/l. Cover crops were again best and where it was established after the plough drew most nitrate away from drains, leaving just 5mg/l,” he reports.

“However, we’ve repeated that trial this year, and it’s the direct-drilled cover crop that appears to be performing best. We’re learning that cover crops make the essential difference, and how successful they are at filtering out nitrates depends on how well they’re established.”

So how is this turned into a public good that farmers are paid for? Brian stresses this is not about creating a blueprint. “Every farm, every situation is different. I’ve found the construction of a drain – whether it’s clay or plastic – has a greater influence over what it ejects than how you cultivate a field, for example. But we can create a discussion, and the more farmers who gather this kind of data, the more we can build a robust basis for payments under an Environmental Land Management (ELM) contract,” he says.

One of the outcomes of the project is a “How to…” guide to help growers design and manage their own simple on-farm trials. “You’ll never get a categorical answer from farmer-led trials, but that’s not to say they don’t deliver value. What we hope is that a few farmers with inquisitive minds will join the discussion and do their own trials. Progress is when you find out for yourself what works best.”

Strategic trials – under test for harvest 2020

A total of seven projects are currently underway at Lodge Farm:

- Managed lower inputs – the effect of reduced fungicide applications on varieties with different disease ratings.

- Early crop biomass – explore ways in which canopy size in late-drilled crops of winter wheat can be enhanced to improve final yield.

- Cover crops – the role of cover crops in reducing nutrient leaching (as featured here).

- Flower strips – the impact of perennial flower strips on beneficial insect and pest populations.

- Very low inputs – the effect of reduced pesticide input applications on pest, weed and disease.

- Variable rate nitrogen –the cost-effectiveness of variable rate nitrogen on high and low biomass areas.

- Repeat baselining – monitoring soil and crop characteristics through the rotation.

A Real Result

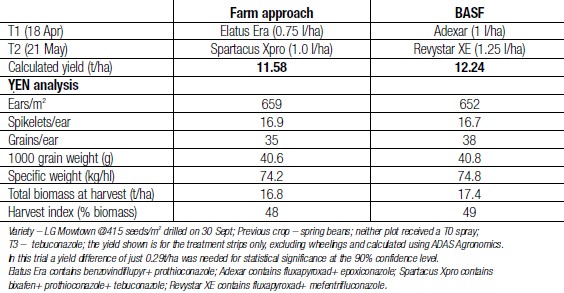

Although Revystar XE brought Brian a statistically significant yield benefit over his farm standard programme, he feels the trial this year didn’t meet the high standard of scientific comparison he aims to achieve.

“The crop was affected by late disease, and normally we’d adjust the spray programme to take account of this,” he explains. “We’d already used Elatus Era at T1 on the farm standard programme, planning to come in with it again at T2, to provide a fair comparison with the Revystar.

“But you can only use Elatus Era once per crop – we had to use a different SDHI/azole coformulation, which I don’t think really gave the BASF programme a fair crack of the whip.”

The loamy sand field received two passes with the farm’s 8m Väderstad Carrier before being drilled with a Sumo direct drill on 30 Sept. “The good conditions meant we established too thick a crop – we were aiming for 350 plants/m² but ended up with 360/m². After a mild winter, the crop had the highest shoot count on the farm at more than 1300/m²,” he recalls.

Brian doesn’t really have a farm standard fungicide programme, but takes regular plant counts through the year and then bases the applications on the crop potential. “The aim is to protect the wheats with potential and cut costs on those less likely to perform.”

With no chlorothalonil (CTL) going on the test field, he dispensed with a T0 spray altogether last year. “The crop reached the end of its construction phase by 8 April, and the plant shoots had settled down to 1000/m², suggesting we were on for a bumper crop of over 11t/ha.”

This is where the “error” was made with the T1 spray. “We were worried that the crop was brewing disease, which is why we opted for the Elatus Era. In hindsight, we should really have swapped the two around and gone first with the Spartacus.”

As it was, the shoot number continued to fall in response to dry conditions, and by the time the ear emerged, the ear count taken by Brian was at 800/m² with a yield expectation of 10.2t/ha – the farm average. By then, wetter conditions were putting the crop under greater disease pressure.

This is where the Revystar appears to have performed, according to the analysis of the YEN results, provided by ADAS’ Susie Roques. She suggests the greater yield resulted from a combination of higher biomass and harvest index, more grains per ear and higher thousand grain weight. “All as one would expect from a treatment which delayed canopy senescence and so prolonged the grain-filling period,” she adds.

“I did notice the Revystar-treated strips hung on to their green leaf for longer,” notes Brian. “But the disease came into the crop after the T2 and T3 treatments. I feel what we used at the T2 timing against Revystar didn’t really offer a fair comparison.”

If the current season was to repeat what happened last year, Brian would cut back on the T1, focusing the spend at the T2 timing. “But if current wet conditions continue, we’ll need to invest more at T1. This year could be very different, and we may have our backs against the wall. On high potential wheats, that’s where Revystar may come in useful, depending on where it’s priced. Also we’ve only seen it in one year and one field, so need a bit more experience with it.”

Although no CTL was used on the test field last year, in line with trial guidelines, Brian doesn’t feel Revystar should be viewed as a CTL replacement. In a low-pressure year, the T0 spray could be replaced with trace elements and biostimulants, he suggests, while careful timing and tailoring of products can provide the correct level of protection for the rest of the season.

“We always farm to the potential of the crop, rather than what we hope it’ll achieve, so I’m not after a silver bullet to help us face the growing disease challenges we face. What Revystar does, however, is add a nice, sharp tool to the toolbox at a time when some of the blunt ones are being removed. We’ve plenty more to learn about how best to use it.”

EJ Barker and Sons 2019 Real Results trials – Appletree field

The Real Results Circle

BASF’s Real Results Circle farmer-led trials are now in their fourth year. The initiative is focused on working with 50 farmers to conduct field-scale trials on their own farms using their own kit and management systems. The trials are all assessed using ADAS’ Agronomics tool which delivers statistical confidence to tramline, or field-wide treatment comparisons – an important part of Real Results.

In this series we follow the journey, thinking and results from farmers involved in the programme. The features also look at some in-depth related topics, such as SDHI performance and data capture and use.

We want farmers to share their knowledge and conduct on-farm trials. By coming together to face challenges as one, we can find out what really works and shape the future of UK agriculture.

To keep in touch with the progress of these growers and the trials, go to www.basfrealresults.co.uk