Combining on-farm trials with a pursuit of variable-rate application has given an Oxon grower a precise insight on how to make the most of his inputs. CPM visits as fungicides are brought into the plan.

By Tom Allen-Stevens

Just a glance at the field that dips and folds before you indicates it’s one that will bring returns from variable-rate applications.

And it does – for almost 15 years, Simon Beddows, farm manager at Coppid Farming, has been using precision farming tools to vary the rate of fertiliser and more recently seed to the 750ha of arable land farmed around Dunsden Green, near Reading. Split-field trials indicate a yield improvement between 0.25-0.75t/ha for a system that costs no more than 0.1t/ha.

What’s interesting about this field, though, is that it’s the site where Simon’s putting variable-rate PGR and fungicide application to the test. “There are parts of the field that will yield more than 10t/ha, and there are areas that will return just 5t/ha. I need to tailor inputs accordingly,” he says.

With very variable soils and some steep slopes, farming is a challenge.

“I already know it works with varying seed and nitrogen, and it simply doesn’t make sense to apply a high input regime to parts of a crop that won’t give you the return – a high dose rate of PGR could even knock it back.”

Joining him to devise a plan for the trials are Simon Parrington and Richard Markham from SOYL. As one of Bayer’s Partners in Performance farmers, Simon Beddows receives help and advice to develop solutions to improve crop performance through the on-farm trials he’s conducting. This year, that help is extending to the variable-rate fungicide and PGR work.

“We won’t make any major changes in management practices until we’ve trialled them on the farm,” states Simon Beddows.

The journey into precision farming started in 2005. “I’ve always known we have very variable soils – it’s not unusual to find 15 soil types in one field, ranging from gravel through to heavy clay. They’re typical of the area and the topography also means we have some steep slopes – farming them is a challenge.”

Traditional P and K testing in a W pattern showed the soils averaged a steady Index 2. But when he asked SOYL to test using a grid pattern, this revealed a range within fields of index 1 up to 4, for exactly the same average value. “It’s like a big hammer hits you and you realise something’s not right.”

Winter wheat yields average 8.5t/ha, but this varies from just 5t/ha to 11.5t/ha, and no two years are the same, he adds. “What we’ve been aiming to do is even up the crops.”

The farm invested in the precision farming kit to manage this. “Initially we had Claas and Renault equipment, but we’ve moved to John Deere now, with everything on Greenstar – compatibility issues were a problem. It’s better now, but ISOBUS is not as seamless as it should be.”

Simon Parrington confirms the industry has ironed out most of the hardware compatibility issues. “There are platforms now to ensure smooth exchange of data, and there’s much greater willingness from manufacturers to work together. It takes a while for the hardware itself to catch up, however.”

Having spent a few years variably applying P and K to even out indices, Simon Beddows moved on to variable-rate N applications. The SOYL system uses satellite images to generate application maps, with rates varying above and below the field average. “We did three years of on-farm trials, and it’s these that gave us the results, with yield increases varying from 0.25-0.75t/ha.” Simon Parrington says ten years of trials undertaken by SOYL indicate a 4.6% average yield increase.

The season at Dunsden Green generally starts with a “smallish” N application to the winter barley and oilseed rape of around 60kgN/ha, variably applied, to get it started. This is then followed up with a blanket application of an NS blend applied to all crops. All applications thereafter are variably applied, with satellite-generated NDVI maps supplied through the season to provide information on canopy variation.

“We’re aiming to even up the crop at the start of the season,” notes Richard. “So in the OSR, applications prior to flowering are geared towards building the required green area index (GAI) of 3.5 – N rate is increased in thin areas and reduced where the crop is thicker. For the final application, this is reversed, and the crop is fed according to its yield potential.”

Following the initial NS blend, the wheats – Skyfall and KWS Zyatt, destined for milling – receive three N applications. The first evens up the canopy while the subsequent doses feed the potential, with a total average of around 260-280kgN/ha applied.

“Variable-rate fertiliser is quite complicated, because the canopy measurements vary throughout the season. Variable-rate seed is based on just one scan, however, so it’s relatively easy,” says Simon Beddows.

This an electrical conductivity (EC) scan that assesses soil type, used as the basis to vary the seed rate. Germination is estimated to vary from 60-95%, based on soil type, and seed rate is adjusted accordingly, with more drilled on the clay caps and less going in lighter soils. Manual edits are built in to increase seed rates for blackgrass patches, for example, and for headlands.

“Last year was the first year we used the system, and as so much of the crop burnt off in the drought, we can’t really assess what difference it made,” he notes. “But with our variable soils, it’s a no-brainer and I expect to see marked improvements in evenness of crop.”

Meanwhile, variable-rate PGR and fungicide are underway, and this will be the third year of split-field trials. “So far we’ve looked at varying the T0 application and have achieved a 0.4t/ha yield increase. I think this comes mainly from not applying so much PGR to the crop on the gravel that doesn’t warrant any – it actually damages the crop.”

The variable rate is achieved by increasing the water volume applied +/- 20% with the average over the field set at 100 l/ha. The applied dose is adjusted so that the maximum recommended rate is put on the part of the crop that receives the full 120 l/ha. “I always apply the spring herbicide as a separate operation anyway, so the variable rate doesn’t impact on other priorities.”

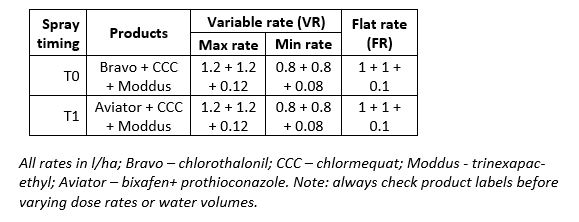

This year’s trial will see both the T0 and T1 sprays varied in randomised tramline segments of the 40ha field – other areas will receive the average

rate. “We’ll be using this field, which is one of the farm’s most variable, and another field which is more consistent to get a good comparison,” notes Simon Beddows.

Again, the extent to which rates of product are varied is limited somewhat by the equipment used – anything greater than a 20% variance in application rate would risk compromising spray pattern.

“It would be ideal to match PGR use to GAI as there’s a threshold below which it’s not needed. But we have to rein back our ambitions to what we can achieve,” he reasons.

There are plans to take it further, however. “Up until now, we’ve sought to even out the crop, but going forward we have to farm the land according to potential.”

With subsidy dropping out of the picture, Simon intends to use the spatially variable data he’s amassed to create different profitability zones in each field. “There are some parts, such as wet corners and some headlands that will never be profitable, and these we’ll take out of production and look to put them into a stewardship scheme.

“Other areas produce a profitable wheat crop, but can lose money when in a break crop, so they’ll be fallowed or go into a cover crop. Then we’ll focus on the most productive areas and that’s where we’ll be tailoring inputs most closely to potential.”

The advantage for Simon is that he not only has the data in layers that can inform how to divide up the fields, he also has the data from his on-farm trials that tells him the return on investment from products applied.

“We’ll not only be improving profitability, but targeting inputs far more precisely to where they’re required. That’ll have environmental benefits, but hopefully it’ll also help reduce the number of chemicals Michael Gove decides to remove from the pesticide armoury,” he notes.

- To follow progress of Simon Beddows’ on-farm trials, sign up to his blog https://simonbeddowsfarmersblog.wordpress.com/

Trials point the path to fungicide future

A keen advocate of on-farm trials, Simon Beddows has been a member of Bayer’s Judge for Yourself group of farmers for many years.

“It does give you an advantage – for example, we got to trial a new fungicide in barley although it’s not yet commercially available for the crop, and achieved a 0.25t/ha yield advantage over our farm-standard treatment. This helps to quantify the benefits of new products, so I can decide where they’re best placed.

“But more importantly we get together with other farmers, and the sharing of techniques and ideas is as valuable as the trials themselves.”

So just how much scope is there to improve margins through variable-rate application of fungicides? “So far, we only have experience with varying the T0 spray, which contributes least to overall yield. So I’m keeping an open mind, and it’ll be interesting to see how the T1 Aviator performs at different rates, according to crop cover.”

Hardware is a limitation of his current set-up, however. “In the future, we’ll hopefully have better disease prediction, and perhaps sensors on the boom that will help tailor product to disease threat. Also, sprayer technology will no doubt advance to allow varying rates of different products in one pass – I hope I’ll have the information from my trials so I’ll know the return on investment of such advances.”

Rosalind Martin of Bayer says that without advances in diagnostic and application technology there’s a limit to how far fungicide rates can be varied. From a product stewardship point of view it’s important when varying rates not to drop below the minimum recommended dose. “Fungicide Futures, a joint initiative between AHDB and FRAG, advises that SDHI resistance in septoria evolves more quickly at higher doses whereas azole resistance is less affected by dose. Therefore, when tank-mixing SDHIs and azoles, a high rate of azole relative to the SDHI should be used,” she notes.

“I’d be nervous about areas here where the prothioconazole rate drops below 75% of a full rate, so below 0.94l/ha of Aviator. That may just be on the thinner areas of crop, and the rate overall averages 1 l/ha, but it won’t make a difference to a septoria spore whether it lands in a thin area or a thick part of the crop – it still needs an effective dose to control it as well as the potential other diseases, such as eyespot and fusarium, that may be present.”

While precision targeting of pesticides makes sense for herbicides and PGRs, she’s unsure whether variable-rate fungicide would bring a benefit. “Our data suggests drilling date, variety and weather beyond April are the three big deciding factors driving disease risk, which won’t vary across a field.”

Bayer is working on a project to measure the Septoria tritici DNA level within a leaf, she adds. “Where the future lies is with better prediction, and then targeting products accordingly. This will allow us to understand how far through the latent period of infection a crop may be before any disease is visible to the naked eye. So accurately timing an application with the right product, based on actual infection level, may be the way to become more precise with fungicides.”

2019 variable-rate fungicide and PGR trial

Partners in performance

Partners in Performance is the result of a long-standing collaboration between Bayer and a group of progressive growers.

It started in 2011 with the launch of Aviator Xpro when growers were invited to trial Aviator on their farm. In these split-field trials Bayer took a back seat with the only demands being the field area for fungicide comparison and crop yield verified over a weighbridge or via combine yield monitor –– everything else was down to the farmer.

Over time this has developed into a club. Each year the farmers meet to discuss results, listen to guest speakers and debate winter wheat management issues.

Farming has always been a challenging business, and with Brexit those challenges have intensified. The margin between profit and breaking even is likely to become even tighter and any incremental gain will be needed for sustainable combinable crop production.

To achieve that the industry needs to work together to share the latest research and thinking, exchange ideas and experiences.

Partners in Performance aims to bring farmers and specialists together to develop solutions to improve crop performance and investment return.