Bayer has been helping growers carry out on-farm trials aiming to eke out the green leaf area of a wheat crop. CPM visits a Lincs grower as he formulates a plan involving nutrition and biostimulants, as well as fungicides.

We can keep grain fill going well into July, provided we can give the crop the resource it needs.

By Tom Allen-Stevens

David Hoyles is someone who’s not afraid to question the advice of ‘experts’, especially if he perceives there’s a product push behind what he’s hearing. But he got a little more than he bargained for after repeatedly asking searching questions during the crop nutrition seminar at the CropTec show in Nov.

“I’ve been looking at the role of amino acids in extending the duration of green leaf area on our wheat crop, which is why I attended the seminar presented by Yara’s biostimulants specialist Antonis Angeletakis,” he explains. “I just wasn’t sure about how much trials work underpinned the results he was relaying, especially research in the UK.”

There’s no rooting restriction on the Grade 1 silts.

A few days after the seminar, he was contacted by Yara UK’s Natalie Wood. “She was there and heard my questioning. She asked if I’d be interested in giving their Biotrac biostimulant a go in some on-farm trials. I’m always willing to try new ideas, and if they don’t work you ditch them and go on to something else. So I’m actually quite excited to see how this product might fit into the strategy we’re developing.”

And it’s the strategy for this season’s on-farm trials he’s now devising with Natalie’s help. Also joining him on the 700ha arable farm at Long Sutton, near Spalding, Lincs, is local Bayer commercial technical manager Jack Hill. As one of Bayer’s Partners in Performance farmers (see below), David receives help and advice to develop solutions to improve crop performance through the on-farm trials he’s conducting.

The focus for David’s trials is extending the green leaf area of the wheat crop for as long as possible, turning available sunlight into grain goodness and ultimately yield. It’s an objective that ties in well with his farm’s soil, climate and location, he explains.

“We’re below sea level here on Grade 1 silts. There’s no rooting restriction and we benefit from sea frets – mist that rolls in from the coast – and heavy dews, ensuring there’s enough moisture and keeping temperatures pegged back a degree or two in high summer. This means we can keep grain fill going well into July, provided we can give the crop the resource it needs.”

There’s a 6-7 year rotation on the farm, with mustard, vining peas, potatoes, sugar beet and beetroot grown alongside wheat. Land is also let out for two years in the rotation to Emmets for field vegetables, leaving around 170ha of wheat. “The better silts have first wheats only, but we do have some second wheats. About 60-70% of this is grown for seed for large local processors, with much of it basic and pre-basic generation. We also grow soft Group 4 varieties for Weetabix.”

The nature of the rotation means the wheat tends to come into fertile soil with plenty of residual N and the five-year average yield is 11.6t/ha. “The farm philosophy is to get the basics right first. So we spend about £30,000/year looking after the drains, for instance. Our four top priorities for the wheat crop are to get the right seedbed, choose the right varieties, get the nitrogen right, and then make sure every operation gets the care and attention it deserves,” says David.

The farm has entered a crop into the yield enhancement network (YEN) every year since it started and tends to rank in among the top performers. The 2018 results form the basis for the conversation around the aspects he wants to focus on in the coming season – the farm came third with a 14.1t/ha crop of Graham, achieving 68% of the site potential.

“On nearly all the parameters we tend to perform better than average – biomass and ear numbers are good for example. If we could increase grains per ear, we’d do even better,” notes David.

But the groundwork for this late season focus starts as soon as the crop comes out of the winter, Natalie points out. “To achieve the optimum yield, you have to make sure the crop has both sink and source – the capacity to yield, as well as the resources available to turn into assimilate.

“Early in the season is when you build the sink, and YEN has shown it’s the crops with plenty of biomass that tend to be the top performers.”

Achieving the right tiller numbers coming out of winter is generally not a problem for David. “We have a low weed burden and most of the other crops in the rotation allow a reasonably early drilling date – late Sept at 300 seeds/m². I have in the past tried raising the seed rate, but that tends to result in weak plants. It’s more about monitoring the crop and pushing it little and often with nutrition.”

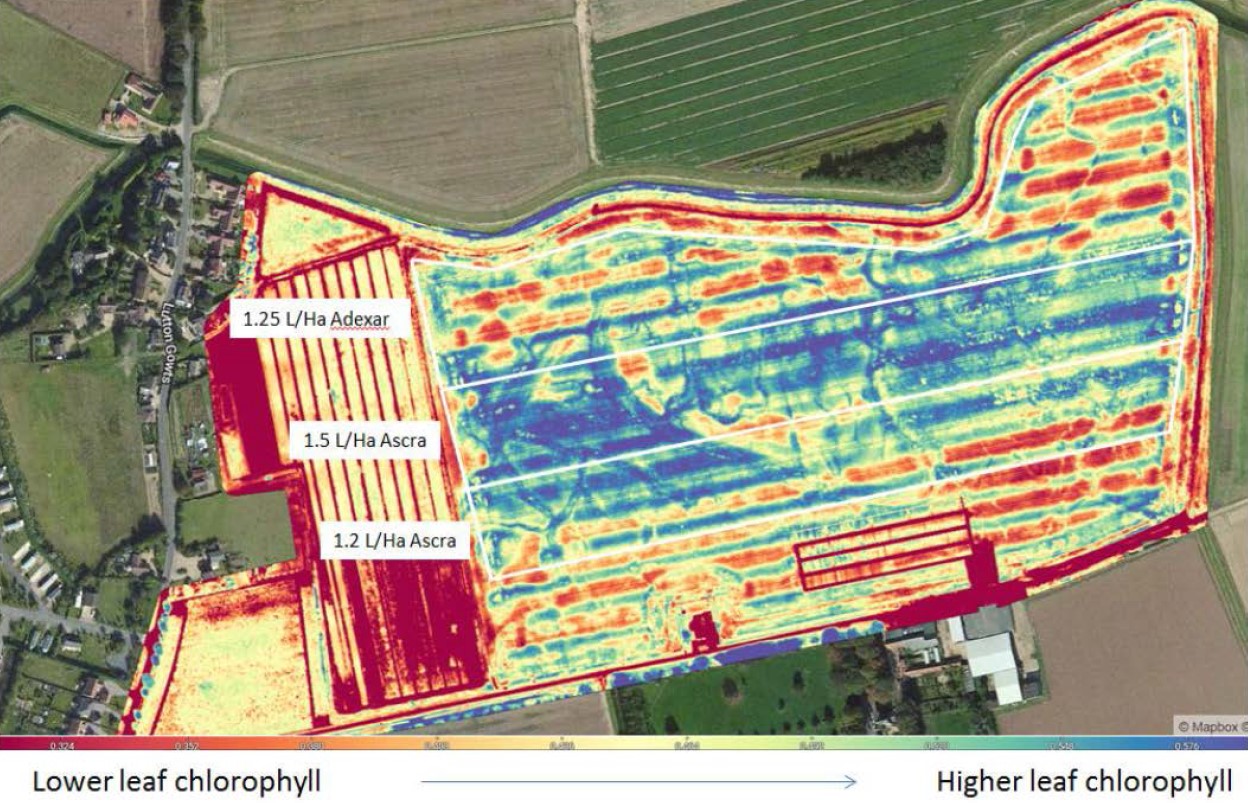

The NDRE map showed there was more leaf chlorophyll in the strips where Ascra had been applied.

He starts the spring with around 1000 tillers/m² and aims to maintain around 800 of these. “We carry out a lot of soil mineral N testing and do vary total applied rates as a result. So we generally apply around 200-220kgN/ha, but last year applied more like 250kgN/ha, for example, as residual N levels were low.”

Natalie confirms that’s the correct optimum N for David’s situation. So when should this be applied? “You tend to get the greatest return from the first N application – our trials in Germany show best results from around 100kgN/ha, while in the UK most growers apply about 70-80kgN/ha,” she says.

The farm lies outside an NVZ and some of the wheat has already received 30kgN/ha, taking advantage of the early favourable conditions. “We go little and often, making 4-5 applications in a season, and the YEN reports suggests this is more than most. The next N application will be at the end of Feb, so we’re on track to give the wheat the early N it needs,” says David.

But it’s not just about N, and this is where the group begins to identify some potential tweaks to the management strategy. “One aspect our YEN report has shown up is that we may not be applying enough sulphur – the grain S was low. What’s more, the average N:S ratio is 17:1, while ours is over 19:1,” notes David.

Natalie confirms it’s a common problem in UK wheat crops. “Routine samples sent in to our labs for analysis show a staggering 97% of these are low or deficient in S. As the crop takes up N, it requires the appropriate amount of S – if one is slightly low, it affects the uptake of the other. But S is prone to leaching, so it’s best to apply it as ammonium sulphate in an N/S compound, especially early on in the season.”

Then there are the micronutrients to consider, she continues. “The important ones are manganese, magnesium, copper and zinc. Mn and Mg affect chlorophyll production, while Cu and Zn are needed for fertility and grain fill. But it’s important to ensure the crop has sufficient levels of these early on, so consider applying these at the T0 timing.

“Boron is a nutrient that’s often forgotten in wheat. It’s needed to generate pollen and a deficiency will affect seed set. But preliminary results from recent trials work we’ve done show there’s a yield advantage in applying this early on, as well as later in the season.”

If the crop is lacking in any of these nutrients, it’ll suffer a ‘hidden hunger’, she explains. This is where there are no visible symptoms, but it won’t be taking up so much N nor putting on the early season biomass during the rapid growth phase that’s needed to lay down the sink.

“I wonder whether we’re going on too late with a lot of our inputs,” remarks David. “We focus a lot of our spend in March, but it seems to be at T0 or even earlier we should be making some of these applications.”

And this is also where he’ll be focusing the Biotrac. Natalie admits there’s limited data for how this product performs in UK crops at present. “The main ingredient is ascophyllum, a seaweed extract that helps a plant combat abiotic stress, such as disease or pest pressure or extreme temperatures. We’re currently offering it to a limited number of growers and are looking to see how it’s best used.”

She believes it’s best applied at the T0 and T1 timings. “Conditions may be cold, but high-performing crops will be putting on growth and they’ll be held back if they experience any stress. It’ll also help them manage pesticide inputs.”

David’s resolved to try out no less than three separate programmes on this year’s crop of Graham winter wheat – one 20ha field will be split with 2 l/ha applied at either T0, or T1 or at both timings, with the results compared with the standard farm treatment.

“I’ve been worried in the past that the weather at T0 or before stem extension isn’t right to apply inputs, but I wonder now whether I’ve held my crop back and that it has a hidden hunger. While it’s crucial to get the nutrition right, It may be that taking stress out of the crop early on will help it build more grain sites later,” says David.

Fungicide focus on greening the flag

The farm has been following a strategic approach to fungicides, and in particular focusing on keeping the top leaves green for as long as possible. “The nutrients you apply build the biomass, but it’s up to the fungicides to keep the canopy green and photosynthesising,” reasons David.

The first step in his approach is variety choice, and he tends to select “cleaner” varieties. “But we’re aiming for high yields and prepared to put the inputs and the management discipline into achieving these.”

A high number of tillers right from the start of the season puts the crop under pressure, he notes. “Already we saw mildew and yellow rust bubbling up in Jan. The cold snap in early Feb has knocked this back, but early applications will need to keep a lid on disease and allow the crop to put on growth.”

Jack Hill agrees and is interested to see how the early biostimulants may interact with the fungicide programme. “We know these products are compatible with fungicides, including SDHIs. What we don’t have much data on is efficacy.

“But we don’t want to make any compromises with the T1 application – if you lose control of disease at this timing, you’ll never claw it back.”

However, on-farm trials at Long Sutton have been looking in some detail at the use of Ascra to retain green leaf area. “We always see a greening effect with Ascra,” says Jack. “Pot trials have shown it increases the chlorophyll in the flagleaf by 11 times over untreated – almost twice what bixafen achieves on its own.”

Bayer trials at its site in Callow, near Hereford, in 2015 showed that a wheat crop can put on an additional 0.49t/ha for every day it holds on to a green leaf area above 37%. So how does this translate into on-farm performance?

The effect was measured using a drone on David’s Judge for Yourself trials in 2017. These on-farm tramline trials put three different T2 regimes side by side in the field. The area was mapped using a multi-spectral camera that picked out the Normalised Difference Red Edge (NDRE) index, highlighting differences at the far-red end of the spectrum.

“This showed there was clearly more leaf chlorophyll in the strips where Ascra had been applied,” notes Jack.

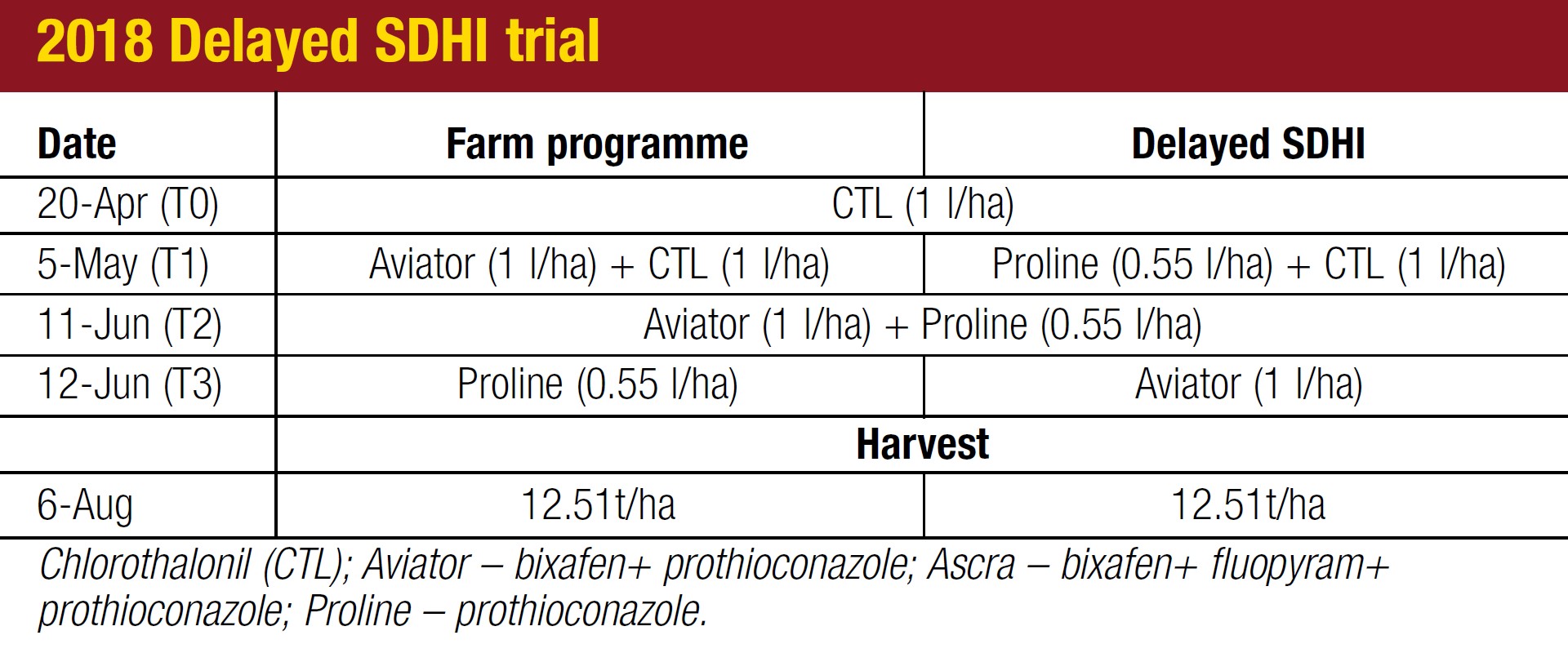

Last year they decided to take the trials one step further, explains David. “I wanted to see if a late SDHI application would make a difference. So we compared Aviator (bixafen+ prothioconazole) at T1 with the same application at T3

“The unusual dry conditions caused the entire crop to senesce at the same time, however, and there was no difference in yield. But we’re going to try it again this year,” he says.

So is it better to delay the SDHI applications until T2 and T3? Jack sounds a note of caution: “If disease pressure is low at T1 and you’re on top of timings, it’s certainly a strategy worth considering,” he says.

“But only 50% of the efficacy of any fungicide can be attributed to the product itself, while the rest is down to application care and timings. If you set your crop up well in the early part of the season, it’ll have the capacity and be healthy enough to make the most of what you give it towards the end, so it’s only a strategy likely to pay dividends if the rest of your crop management is as good as it can be.”

Partners in performance

Partners in Performance is the result of a long-standing collaboration between Bayer and a group of progressive growers.

It started in 2011 with the launch of Aviator Xpro when growers were invited to trial Aviator on their farm. In these split-field trials Bayer took a back seat with the only demands being the field area for fungicide comparison and crop yield verified over a weighbridge or via combine yield monitor – everything else was down to the farmer.

Over time this has developed into a club. Each year the farmers meet to discuss results, listen to guest speakers and debate winter wheat management issues.

Farming has always been a challenging business, and with Brexit those challenges have intensified. The margin between profit and breaking even is likely to become even tighter and any incremental gain will be needed for sustainable combinable crop production.

To achieve that the industry needs to work together to share the latest research and thinking, exchange ideas and experiences.

Partners in Performance aims to bring farmers and specialists together to develop solutions to improve crop performance and investment return.