30% of wheat grown in the UK still doesn’t receive sulphur applications however, as a macronutrient and to avoid the risk of deficiency, every cereal crop should have some sulphur applied to it – every year. CPM finds out more.

Not all sulphur fertilisers are the same and timing will depend on a number of factors – it is always useful to check what you are applying using the ‘4Rs’, advises Tim Kerr, Fertiliser Manager with Hutchinsons.

Ask yourself is it the right type of fertiliser, are you applying the right rate, are you applying it at the right time and finally, is it going on the right place i.e. is it being applied accurately?

Nitrogen and sulphur work very closely together and demand for N and S is very closely correlated; one major function of nitrogen and sulphur is amino acid production and both elements are required together to ensure they are both utilised efficiently in this process.

“Currently the most common current practice is for sulphur to be applied with nitrogen applications – generally with the first or second application,” says Tim.

“In fertiliser terms there is a fixed ratio of the requirement of N and S – work on 5-1 for cereals.”

“Between GS 31 and 39, the N uptake averages 2.5kg/ha per day. At the same time the S uptake is on average 0.5kg/ha per day. Between GS 39 and 59 N uptake averages 2kg/ha per day and S uptake mirrors this at 0.4kg/ha per day.

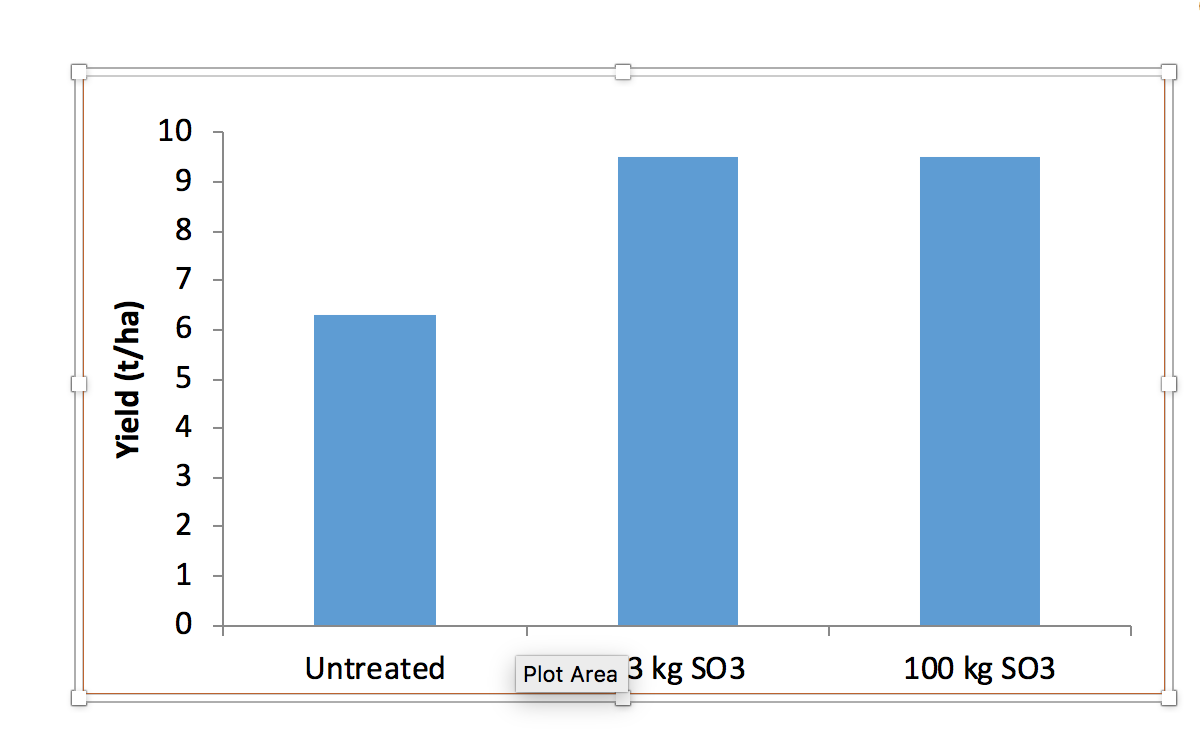

Tim refers to replicated trial work carried out by Yara and Hutchinsons in 2018, which showed the very significant response to sulphur, whilst also highlighting that applying too much sulphur was of no economic benefit.

Hutchinsons Yara Trials response to sulphur

Tim advises milling wheat growers to apply 50kg/ha of SO3 to reduce the risk of acrylamide formation during processing.

“This is a good level to aim for – either that or use the 5 to 1 calculation (e.g. 200kg/ha of N = 40kg/ha SO3).”

What product?

“There is frequent debate over the right choice of nitrogen fertiliser, whilst the suitability of the sulphur is often overlooked.”

He explains that whilst ammonium sulphate is widely used and is rapidly available it can also be at risk of significant nitrogen and sulphur losses.

“Whilst the risk of N losses via volatilisation from urea are well documented, research tells us that ammonium sulphate can be equally at risk of volatilisation on high pH soils – with potential nitrogen losses of the same magnitude as urea. “

“Equally the sulphate fraction is water soluble – so can be prone to leaching below the rooting zone before it is utilised.”

Calcium sulphate is also used in some NS compounds – and these products would be more appropriate for alkaline soils and are less susceptible to leaching of sulphur. It is therefore important to know what form of sulphur you are applying, Tim adds.

He suggests that in order to try to match soil supply with crop demand it is preferable to apply nitrogen and sulphur together, if practical, at each nitrogen application – and this can be achieved with granular or liquid NS fertilisers.

“One alternative approach is to combine spring potash applications with sulphur.”

A new product now available to UK growers is Potash Plus (analysis 37% K2O, 3% MgO 23% SO3) which is a granular compound now being produced by ICL at the Cleveland Potash mine – it is a combination of MOP and PolySulphate.

“The sulphur in PolySulphate comes from three sources – calcium, magnesium and potassium sulphate. This has been shown to release S over a long enough period of time to meet the crop’s requirements for sulphur over the major growth period and is also unaffected by pH so a useful alternative to ammonium sulphate.

“Applying potash in the spring is increasingly seen as a very effective way of applying K to cereals – to meet the peak uptake requirements. The balance of K and S in Potash Plus will suit many UK soils and it should be a very valuable addition to the toolbox for managing sulphur effectively,” says Tim.

“Using Potash Plus will allow straight nitrogen to be used – removing the need to buy NS products.”