Getting the best out of phosphate may seem like a fine art with so many products on the market and varying opinions on application windows. CPM explores the options in search of strategies that suit the individual farm.

To run phosphate reserves down is a dangerous business and can be expensive to build back up.

By Charlotte Cunningham

Phosphorus is one of the most important macro-elements required for optimum plant nutrition and particularly crucial in the establishment stage. For those whose soils are naturally lacking in this essential nutrient, phosphate fertilisers have long been the go-to solution for reaching target levels for optimum crop productivity.

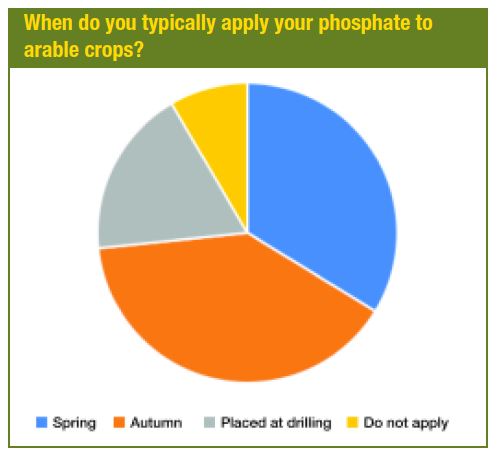

Despite it being such a widely used nutrient, opinions differ over uptake levels, when phosphate is most utilised, and what is the best source. So it comes as no surprise that in a survey carried out by CPM and Yara 64% of growers believed 70% of phosphate is taken up in the spring, while 28% the majority is taken up in the autumn and a further 8% believed most is utilised in the winter. This may highlight the need for clarification on the best strategy.

Traditionally, growers have applied phosphate in the autumn. This was backed up in the survey as 40% of growers stated they apply during this window. However, with more understanding over the mobility of phosphate in the soils, an increasing number of farmers are now applying more phosphate in the spring.

“Growers certainly understand more about the lack of mobility in phosphate – when applied to cold soils it’s virtually immobile,” explains Tim Kerr, fertiliser manager at Hutchinsons. “While uptake itself is relatively consistent throughout the growing season, most of the growing is done in the spring meaning there is a greater demand for it at this time.”

Crop demand in the autumn is in fact so low that it may be worth avoiding an application all together, adds Natalie Wood, agronomist at Yara. “Anything applied in the autumn is unlikely to give the supply that’s needed in the spring. Instead of phosphate, a seed treatment or foliar application can help to boost crops during and after establishment.”

Placing phosphate at drilling is also becoming more popular thanks to a better understanding of phosphate mobility, alongside the development of technology to assist growers, explains Tim. “Available phosphate reserves can be locked up very quickly in the soil, but if you enrich the area around the seed you should be able to maintain performance, and subsequently yield.

“Ten years ago at Cereals you wouldn’t have been able to find a drill that allowed you to place phosphate next to the seed – so that is big change.”

Placing at drilling is a resurgent and so research is being undertaken to assess the validity of it, explains Roger Sylvester-Bradley, head of crop performance at ADAS. “Tramline tests are being carried out at the moment after it was noted in a LINK-funded small-plot work that placing at drilling only proved beneficial in spring crops, not autumn. There’s logic in it, but we don’t yet know whether it will pay off.”

Despite it being an essential nutrient, 8% of growers revealed that they don’t apply phosphate at all. “If growers are maintaining their soil reserves, not applying phosphate is fine,” explains Tim. “However, to run reserves down is a dangerous business and can be expensive to build back up.”

Despite it being an essential nutrient, 8% of growers revealed that they don’t apply phosphate at all. “If growers are maintaining their soil reserves, not applying phosphate is fine,” explains Tim. “However, to run reserves down is a dangerous business and can be expensive to build back up.”

If an autumn application is required it ideally needs incorporating rather than just leaving it on the soil, he adds.

When it comes to application, 48% of growers revealed they undertake three-yearly routine soil sampling to determine rates of application. “Growers need to make sure they collect representative samples from across the whole field,” explains Natalie. “Ideally this would be about 20-25 samples – avoiding any odd areas such as water-logged patches – collected in the usual ‘W’ pattern.”

While working from soil sample results is sound method for deciding application rates, growers may also want to look at crop removal to make sure they’re maintaining soil reserves, says Tim. “It can work well to use a combination of approaches.”

Roger agrees: “A combined approach is the advice given in the RB209 guide. Use soil indices and take into account the crop offtake. Operating a balanced approach is key to getting the best out of phosphate.”

Precision farming is growing in popularity, with technological developments pushing growers towards greater use of variable rate application maps. However, according to the survey, only 36% of farmers utilise variable rates for phosphate application, compared to 64% who use generic, uniform application. “The use of variable rate applications is different for phosphate as it moves so little in the soil,” says Natalie. “Unless technology improves to enable us to collect a more accurate soil sample then uniform applications are a good option.”

In contrast, Tim reckons there is definitely a case for variable rates where there are varying soil types. “However, if you’re applying purely for phosphate maintenance, stick to uniform rates.”

While precision application is no doubt more expensive, it is more reliable, adds Roger. “Because you are making many more assessments per field, by identifying zones where you do and don’t need phosphate you can definitely make precision application pay.”

Application rates will vary depending on the starting point of the soils, however, the survey revealed that most growers are opting for average rates of 50-75kg/ha of P205, which would be a fairly adequate level for maintenance, explains Tim.

Application rates will vary depending on the starting point of the soils, however, the survey revealed that most growers are opting for average rates of 50-75kg/ha of P205, which would be a fairly adequate level for maintenance, explains Tim.

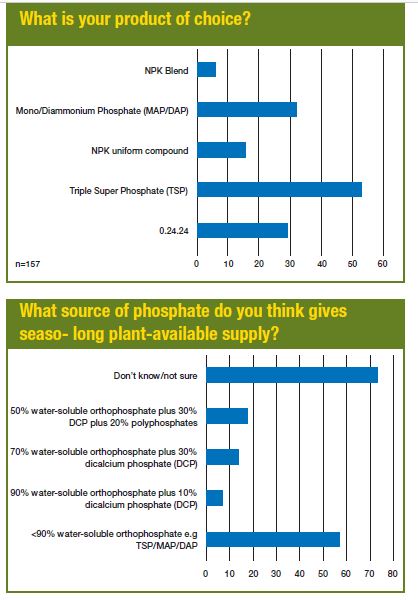

With so many phosphate products and different sources on the market, finding the right one to meet the needs of the farm can seem quite a daunting task. The survey revealed that growers were using a number of different options, with the most popular being Triple Super Phosphate (TSP) – which was the product of choice for 39% of growers.

Despite their popularity, products like TSP, mono or diammonium phosphate (MAP/DAP) are more than 90% water-soluble orthophosphate. This means that while phosphate is immediately available after application, over 40% becomes locked up within two weeks, causing issues in the spring, explains Natalie. “For those growers looking to optimise spring applications, the best course of action is an NPK compound used at the first nitrogen application, followed by a foliar treatment if needed later in the season.”

Only 12% of growers noted NPK as their product of choice, with 4% using a blend and 8% opting for a uniform compound. “More people are using straights now rather than blends,” says Tim. “I think there is now a greater understanding that phosphate is needed right through the whole crop cycle.”

Blends still hold a place however, with 21% of growers choosing 0:24:24. “This is fine, providing the recommendations for both P & K are being followed,” adds Roger.

The survey suggests there remains a lot of confusion around sources of phosphate –particularly which source gives plants season-long supply. 43% of growers didn’t know or weren’t sure when it came to knowing which products would provide them with continuous phosphate availability. “I’m not surprised people aren’t sure,” says Tim. “Most growers would just expect phosphate fertiliser to provide sufficient plant availability without taking into consideration how valuable that source is – there’s more to phosphate than meets the eye.

“If there was a better understanding of how phosphate works in the soil, growers would be able to make more informed decisions.”

Less water-soluble sources of phosphate can give better plant availability, adds Natalie. “Using a product that is 50-70% water-soluble orthophosphate with additional dicalcium phosphate (DCP), and polyphosphates means some that phosphate is immediately available but also allows root exudates to excrete root acids and supply phosphate to the plant as and when it needs it.”

There is a lot of variation in how different products work, and huge misunderstanding about the differences between them, she says. “But the more efficiently phosphate is used, the better the yield will be.”

Turning to other forms of phosphate, there is a lot of discussion around the benefits of foliar phosphate and phosphite. “Both sources remain fairly unproven, particularly with phosphite as not enough research has been done to prove its worth,” says Roger.

Despite this, 41% of growers stated that they use foliar phosphite, while a further 26% use foliar phosphate.

Though phosphite is derived from phosphoric acid, it’s not actually a source of phosphate – something that is very important to remember, warns Tim. “Phosphite doesn’t supply any quantity of phosphate to a plant, nothing meaningful anyway. What it does do however, is stimulate root growth which in turn helps plants to mine phosphate out of the soil.”

While Natalie agrees that foliar phosphate can improve root growth and plant health, she reckons in the first instance it’s worth doing a tissue sample in the spring to identify whether the crop is deficient.

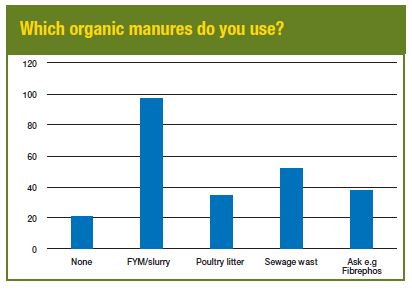

As well as manufactured fertilisers, organic manures can also provide a helpful source of phosphate. The importance of organic supplies was highlighted in the survey with just 12% of growers saying they don’t use any at all, and 58% revealing they use farmyard manure or slurry. “Wherever possible, farmers might want to consider some form of organic manure,” says Tim.

Doing so is useful for both the grower and the environment, adds Roger. “The more we can encourage organic manures the better, as this maintains phosphate in available forms for longer while recycling it rather than mining it.”

“There is a big issue with phosphate in developed agriculture as we are net importers of phosphate. This in turn can cause issues with water pollution.”

While all sources of organic manures have the potential to supply beneficial phosphate, their value can vary. Analysing organic manures is considered the only way to gain an insight into exactly what nutrient content it contains, so it comes as no surprise that 56% of growers do analyse organic manures.

However, this means that 44% don’t, so is there really benefit of investing in analysis? “Analysis is good value for money, as it allows you to make the most out your manure – it’s only sensible to know what you’re applying,” says Roger.

The RB209 guide is a good indicator for those growers looking to keep costs down, says Tim. “It’s important to know what the value of your organic manure is. However, RB209 guideline levels are pretty accurate. While analysis is good, it might not be worth doing every lorry load.”

But it is definitely worth investing in some analysis, says Natalie. “If you haven’t got an analysis, how can you work out what you’re getting out of it? It’s also really important for record keeping and NVZ requirements – you need to know what you’re putting onto the soils.”

Top tips for phosphate management

- Know your pH – make sure you have a sound understanding of your starting point and if you are in a high area or not.

- Evaluate the phosphate source you plan to apply, especially when placing phosphate at drilling. Will it provide the availability you require? This can help when making product decisions.

- Make the most of organic manures

- Regularly soil test to keep an eye on nutrient levels

Clear strategy is a winning solution

Congratulations to our lucky winner Peter Lankfer from Cambridgeshire who responded to the CPM/Yara survey on phosphate management and has won the fabulous prize of a Davis Vantage Pro2 wireless weather station.

Congratulations also go to our runners-up William Thomson, from East Lothian, who wins a season’s use of a Yara N tester for nitrogen management and Paul Hayward, from East Yorkshire, who will receive a soil corer.

All three CPM readers responded to the survey and completed the tie-breaker question, explaining the best way to obtain value from phosphate fertiliser. The common theme that impressed the judges was knowledge of a clear strategy when it came it using phosphate.

The light-hearted winning answer from Peter was: “Apply in the winter and spring in optimum conditions, followed by large gin and tonic!”. William said: “Know your soil status and apply accordingly, investigate all sources for best value.” Paul’s answer was: “Understand its most effective application.”

The aim of the survey was to explore the different phosphate options and delve further into when is the best time to apply them. To take part in the next survey, make sure we have your correct details by emailing angus@cpm-magazine.co.uk