With the diversity of cropping changing on many arable units, the level of risk with some products could cause a slip-up on sprayer hygiene if the system’s under pressure. CPM seeks expert advice on potential problems.

Not all ALS products pose the same risk.

By Tom Allen-Stevens

Good sprayer hygiene is largely taken for granted. Sprayer operators who stay up-to-date with NRoSO training are trusted to know the risks and put in place a wash-out procedure that minimises the possibility of any problem.

Spray minute amounts of certain herbicides onto non-target crops and you risk severe crop damage, warns Alister McRobbie.

But it’s often not until a problem arises that it becomes clear there was a simple oversight in what was assumed to be good practice. What’s more, there are highly active products used on most arable farms today, which vary considerably in how easily residues can be cleaned from the sprayer, notes Alister McRobbie of Dupont.

Then there’s the three-crop rule and a general move towards more diverse cropping. This introduces new critical control points onto farms, argues Stuart Maltby of Frontier, not just in terms of damage to non-target crops, but with residues of non-approved pesticides found on produce.

These new, heightened risks mean it’s probably worth spending a little time reviewing your wash-out procedure before the spray season starts in earnest.

Why is sprayer hygiene important?

One of the wonders of modern herbicide technology is that you can apply a product through a sprayer at a concentration of just 0.01% and achieve an effective kill of target weeds. But the greatest strength of these herbicides is also a considerable risk – spray minute amounts onto non-target crops and you risk severe crop damage.

Another risk today, and one of arguably rising importance, is where residues of pesticides of any group are found on crops where there is no label clearance for the product. Modern analytical equipment can detect amounts as low as 0.1 parts per billion, which can result in a costly produce rejection, and serious repercussions for the business responsible, as well as for the industry in general.

The products that pose the greatest risk of damage to non-target crops are the ALS herbicides, as they are highly active with a dose rate of often just a few g/ha of active ingredient. These include sulfonylurea (SU) herbicides, such as Ally Max SX (metsulfuron-methyl+ tribenuron-methyl) as well as products such as Spitfire (florasulam+ fluroxypyr), Cleranda (imazamox+ metazachlor) and Atlantis (iodosulfuron +mesosulfuron).

When do problems arise?

Pesticide usage survey figures suggest around 9 million ha of herbicides are applied to cereals, approximately 40% of which are ALS herbicides – it’s a figure that’s been rising year-on-year since they were introduced. The greatest risk of crop damage occurs when the sprayer switches from applying herbicides on cereals to other products applied to sugar beet, oilseed rape, field vegetables or pulses and an adequate wash-out procedure has not been carried out.

The AHDB’s Early Bird Survey of GB farmers’ planting intentions for 2016 shows that the area sown to pulses alone is set to rise by 15%. Problems with grassweeds have seen many arable units make a general shift into spring cropping, while others have diversified the cropping portfolio in response to new CAP rules or economics of commodity crops. Product withdrawals and label revocations have also limited the crops approved for treatment with certain pesticides.

The result of these changes is that many sprayer operators may now be making applications with a high risk of cross-contamination that did not exist previously. More cereal herbicides applied in spring put brassicas and sugar beet at risk, for example, while an operator may not be aware of the potential consequences of a label change.

Where can residues persist in the sprayer?

Any point in a sprayer where liquids can remain stationery are where potential problems arise. Common areas include:

- The induction hopper – under the rim that may not be rinsed, as well as pipework leading to the tank.

- The sight glass

- Sprayer valves

- The main filter – any deposits of dirt can collect spray residues

- Spray lines where there is no prime-and-purge system

- Nozzle bodies

- The sump

Quick-fill systems should not be used during wash-out, as this can bypass the induction hopper, meaning residue or contaminated washings may not be flushed through.

Water-dispersible granule (WG) formulations in particular are a higher risk because in the sprayer they are partly in solution and partly in suspension. Small particles, under pressure may collect in the nooks and crannies.

Another problem is the common misconception that applying thousands of litres of liquid fertiliser will help wash out herbicide residues. In actual fact, the fertiliser coats any residue in the tank with a film so they persist in the sprayer until another pesticide is introduced.

If a sprayer is left to stand for any period of time before washing it out, particularly in warm weather, residues will often dry to surfaces such as the tank walls and these will become harder to clean. It’s poor practice to leave a sprayer unwashed overnight.

What products help?

When Dupont introduced SU herbicides in the early 1980s, the company also introduced AllClear to help operators wash sprayers out thoroughly between jobs. Originally launched as an ammonia-based product, today the formulation is an ammonia-free surfactant and less hazardous, but is very effective at removing residues and should always be used as part of any wash-out procedure, especially when using ALS herbicides.

Not all ALS products pose the same risk, however. DuPont SX SU products have been specifically formulated to be truly soluble granules. This means that they disperse fully as soon as they are added to the water in the sprayer induction bowl. This greatly reduces the risk of contamination common with WG formulations highlighted above.

What’s the best practice routine?

Whatever the wash-out procedure, the best place for any product is on the crop for which it’s intended. So it’s important when spraying a field to leave an area where washings can be sprayed without the risk of exceeding the maximum dose.

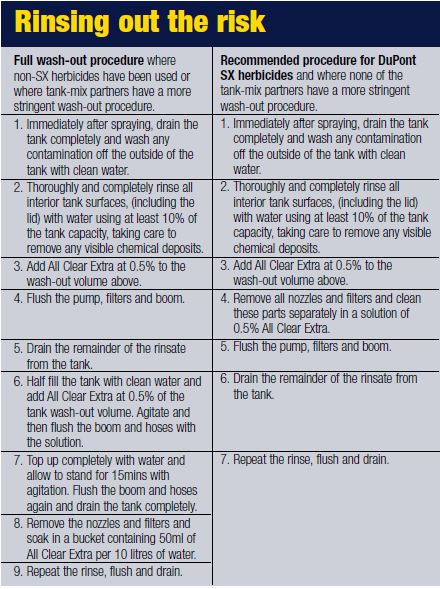

While manufacturer guidelines stated on product labels should always be followed with regard to wash-out, a full tank wash-out procedure (see panel below) is generally necessary for non-SX ALS herbicides. If using just SX herbicides, a shorter wash-out procedure can be followed, saving both water and time.

When disposing of washings, the code of practice for the safe use of pesticides on farms and holdings should be adhered to, particularly in relation to spraying onto land growing or intended for planting with sensitive crops.

How can the risk be minimised?

Sprayer operations should be carefully planned, so that the most sensitive crops, sprayed with the lowest-risk pesticides, are treated at the start of a day’s spraying, with highest-risk situations left towards the end. Insecticide and fungicide on OSR or pulses and blight sprays are examples of operations that should be put first.

Try to use products that minimise the risk of problems with cross-contamination. Choosing DuPont SX formulations of ALS herbicides will greatly reduce the risk associated with this group of chemistry, as well as reducing the time spent washing out the sprayer.

The sprayer operator should always bear critical control points in mind. A common error is failing to drain the tank completely – as soon as the pump is next switched on, this can result in contaminated liquid passing to nooks and crannies in the sprayer before any fresh water is introduced.

Which sprayer options help?

A clean-water rinsing tank is standard on most sprayers, and is essential for an efficient and effective wash-out

procedure. Likewise, most sprayers have a rotating-nozzle or spinning-disc device to clean the inside of the tank, and these are also essential.

Many sprayers have prime-and-purge systems that allow circulation to the booms with the nozzles switched off, and these help reduce the risk of problems with residues.

The best sprayers have automated wash-out procedures that are operated from the tractor cab with switches or via a control panel – such options are well worth specifying when buying a new sprayer.

Sprayer design eases wash-out worries

While washing out sprayers is an important task, it can also be a time-consuming operation when the sprayer could be at work. This is a detail not lost on Mark Gill who, in partnership with his brother and a neighbouring farmer, trades as Yare Valley Farming, a company based at Barnham Broom in Norfolk.

“Like many farms in this part of the country, we grow a wide variety of crops and it’s essential to avoid damage caused by harmful pesticide residues remaining in the sprayer,” he says. “I know washing can take up valuable time but with modern sprayer designs and the right product formulations, this can be reduced significantly.”

He farms a total of 800ha, the majority of which is down to winter wheat, winter and spring barley with 40ha used to grow forage maize for the farm’s 300 dairy cows. There’s also 200ha of maize grown for an AD unit and 40ha of main crop potatoes on rented ground.

With this diverse cropping regime, the sprayer, as on many farms, is a key machine. In this case, it’s a Chafer Sentry trailed sprayer with a 6000-litre tank and 36m boom.

“We apply liquid fertiliser as well as a broad range of pesticides so while we don’t always fill the tank to full capacity, it’s useful to have it available to maximise output when working some distance away from the farm on the potatoes or maize, for example,” he notes.

Keen to see the sprayer in work and not spending valuable time washing out the sprayer, Mark Gill highlights the Sentry’s rinsing system which is activated by an in-cab ‘Jet Flush’ switch and powers clean water through the spray lines.

“The chemical induction hopper has a rotating nozzle to clean all surfaces, the non-porous stainless steel tank cleans easily and there’s a filter which can be flushed to remove residues. Efficient cleaning is further enhanced by having a hydraulically powered centrifugal pump which can work at pressures of up to 100psi.

“Used in conjunction with DuPont’s SX formulations and the company’s All Clear Extra, washing time becomes a relatively speedy affair which doesn’t intrude excessively on a day’s spraying.”

Other time-saving features include a programmable fill volume to allow the operator to concentrate on adding product rather than having to spend time watching a level indicator.

The Sentry sprayer was also specified with an automatic boom section shut-off that draws information from the tractor’s positional GPS system and helps ensure there is no over-dosing on the headlands.

“It’s a sprayer which meets modern farming requirements – rapid efficient rinsing which is bound to be increasingly required given the diversity of crops we’re growing. There’s also a wide-working twin-line boom and automatic section cut-off. Above all, it’s a sprayer which is straightforward to use and liked by the operator, which reduces the chances of any problems,” he concludes.

Sprayer wash-out: top tips

- Assess the risks – work out what the critical control points are, which chemicals and crops are high risk, and plan spraying to avoid potential problems.

- Review the wash-out procedure – the best place for any pesticide product, including its residue, is on the crop for which it has label approval.

- Consider the formulation – look for products, such as SX formulations, that are less likely to result in residues.