The results of a T3 survey by Bayer show there’s still scope for growers to improve farm practice when it comes to fusarium ear blight (FEB) control. CPM digs into the detail.

When the anthers are first visible protruding from the middle florets of the ear, it’s a good guide to the optimum spray timing.

By Rob Jones and Lucy de la Pasture

On the whole the results of the survey are positive, says Bayer’s Sam Harvey, indicating many farmers are heeding the advice of experts that fusarium and mycotoxin control is now a necessity for both premium and feed wheat markets. But when it comes to getting the T3 timing right to protect the entire ear, not all are following best practice.

The survey reveals that the wheat area treated at T3 by both milling wheat and feed growers was 79% and 75% respectively. Given the prospect of mycotoxin contamination and yield loss from fusarium and microdochium, the fact that 21–25% of growers are leaving the ear unprotected is quite a surprise, says Fera’s Dr Phil Jennings.

FOOTER Source: Bayer T3 survey 2018

He believes the area not covered at T3 is probably down to weather rather than a deliberate policy not to spray. “The threat from fusarium isn’t just due to the mycotoxin-producing species, there’s also a potential yield penalty from infection. Since 1998, we’ve seen more disease caused by microdochium and this can reduce grain quality and final yield by as much as 10%.

“With fusarium the key driver is humid and showery weather around flowering, something we’re seeing more frequently. Even if early season inoculum build-up has been checked by cold and wet weather, the picture can change quickly given the right conditions for infection by FEB pathogens during flowering.

FOOTER Source: Bayer T3 survey 2018

“Favourable conditions for FEB infection could also hamper spraying operations. I think this is probably why not every wheat field received a T3,” he suggests.

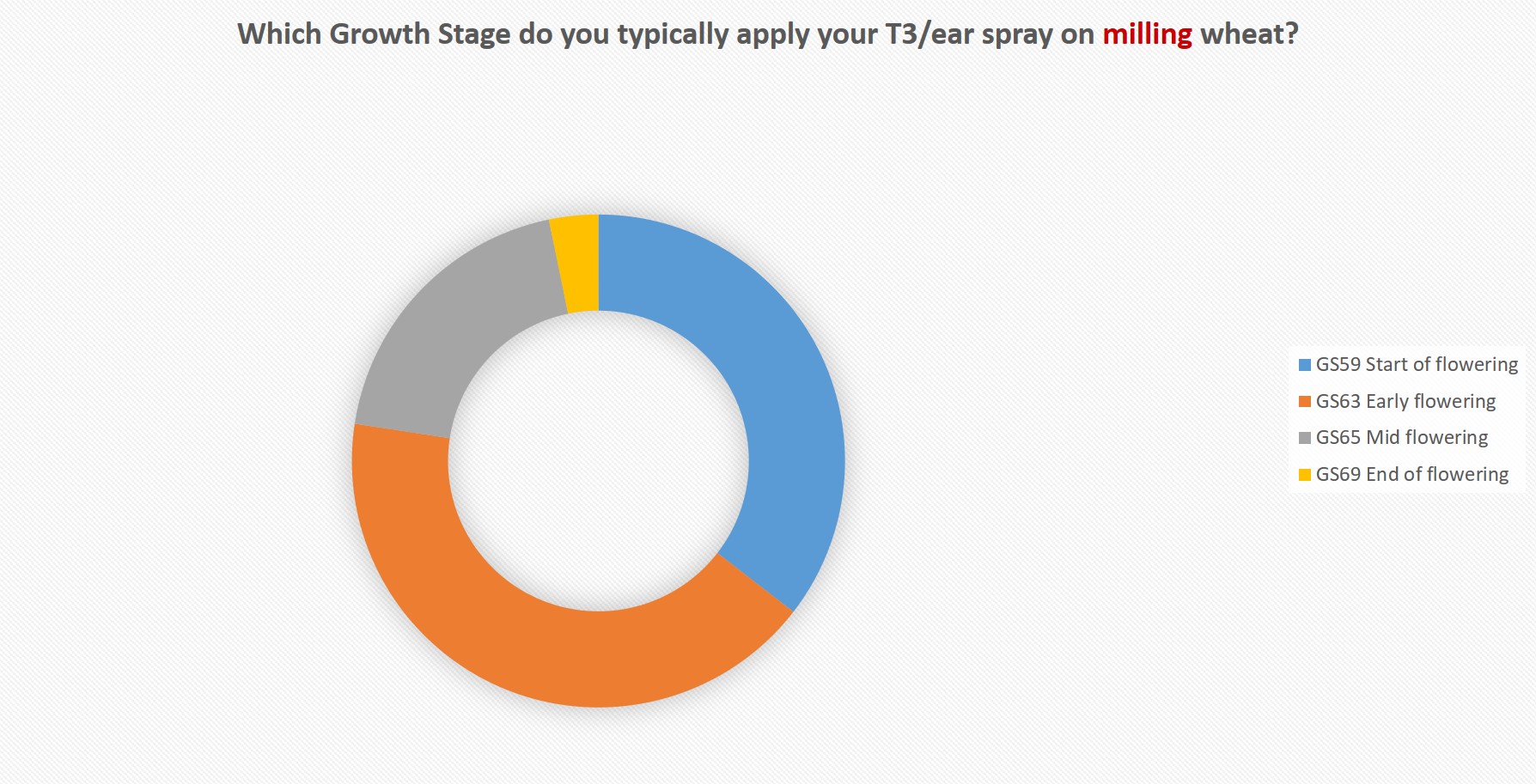

The survey suggests some confusion may still exist around the ideal timing. Some growers are still going either too early or too late. Again this might be down to a poor weather forecast, interruptions or other tasks taking priority, but whatever the case it is likely to result in impaired fusarium control, he points out.

Phil acknowledges it’s a hard timing to hit because the window is so narrow, but he says growers must aim for early to mid-flowering .

FOOTER Source: Bayer T3 survey 2018

‘It’s possible to get infection on the ear as it emerges, but that’s the exception rather than the rule. Prothioconazole is the most protective and curative fungicide option, but even here the window is narrow.

“Just ahead of mid-flower is the best application timing because it provides protection for the flowering period and a bit of kick-back. However, the protective activity is less with secondary azoles,” he warns.

The timing of T3 sprays is an area he feels warrants further investigation. “We need to establish whether missed timing is down to weather or workload-related issues, or is it due to a misunderstanding about when to time sprays for FEB control?”

Early to mid-flower is the ideal time to target Fusarium species because the fungus complex initially grows on the spent anthers that dangle from the florets post-anthesis, adds Sam.

“The anthers act as a route to infection of the developing seed tissue. When the anthers are visible protruding from the middle florets of the ear, it’s a good guide to the optimum spray timing. You have to apply the fungicide at this time to coat and protect the ear and anthers, before the disease starts to infect,” he advises.

Sam acknowledges total control of the fusarium complex from fungicide sprays is unlikely, but he believes one of the reasons Proline (prothioconazole) is the better option at T3 is because it widens the spray window a little further. In addition, it’s the only effective active ingredient against microdochium, he points out.

“Folicur (tebuconazole) has an effect on the toxin-producing Fusaria species, but Proline has the edge. It can provide an extra two days activity either side of flowering without any drop off in performance. Essentially Proline offers some flexibility to a timing that’s almost impossible to practically get absolutely right across the whole crop,” he says.

FOOTER

Source: Bayer T3 survey 2018NIAB’s technical director Bill Clark believes growers can easily be caught out when it comes to T3 timing because flowering may occur as soon as 7-10 days after the flag leaf spray has been applied. He points out that using prothioconazole early in flowering will usually decrease fusarium pressure, depending on the season.

“The T3 application needs to be thought of as a specific spray to target FEB rather than as a top-up for the T2 spray. A decent T2 won’t need added protection and it’s a mindset that encourages the interval between flag leaf spray and the T3 spray to be stretched,” he says.

In the survey, 43% of growers said they would consider a T4 and of those, most cited additional fusarium control as a reason.

Phil says a T4 can have benefits, but it very much depends on the season. “Crops are at their most susceptible during flowering. Sprays timed at early to mid-flowering give protection going forward and a little kick back against infection that might be present.

“But if the flowering period is extended, for example due to cold temperatures, a second application can act as a protectant top up. If flowering is short then a T4 will add nothing to a well timed early-mid-flower spray,” he advises.

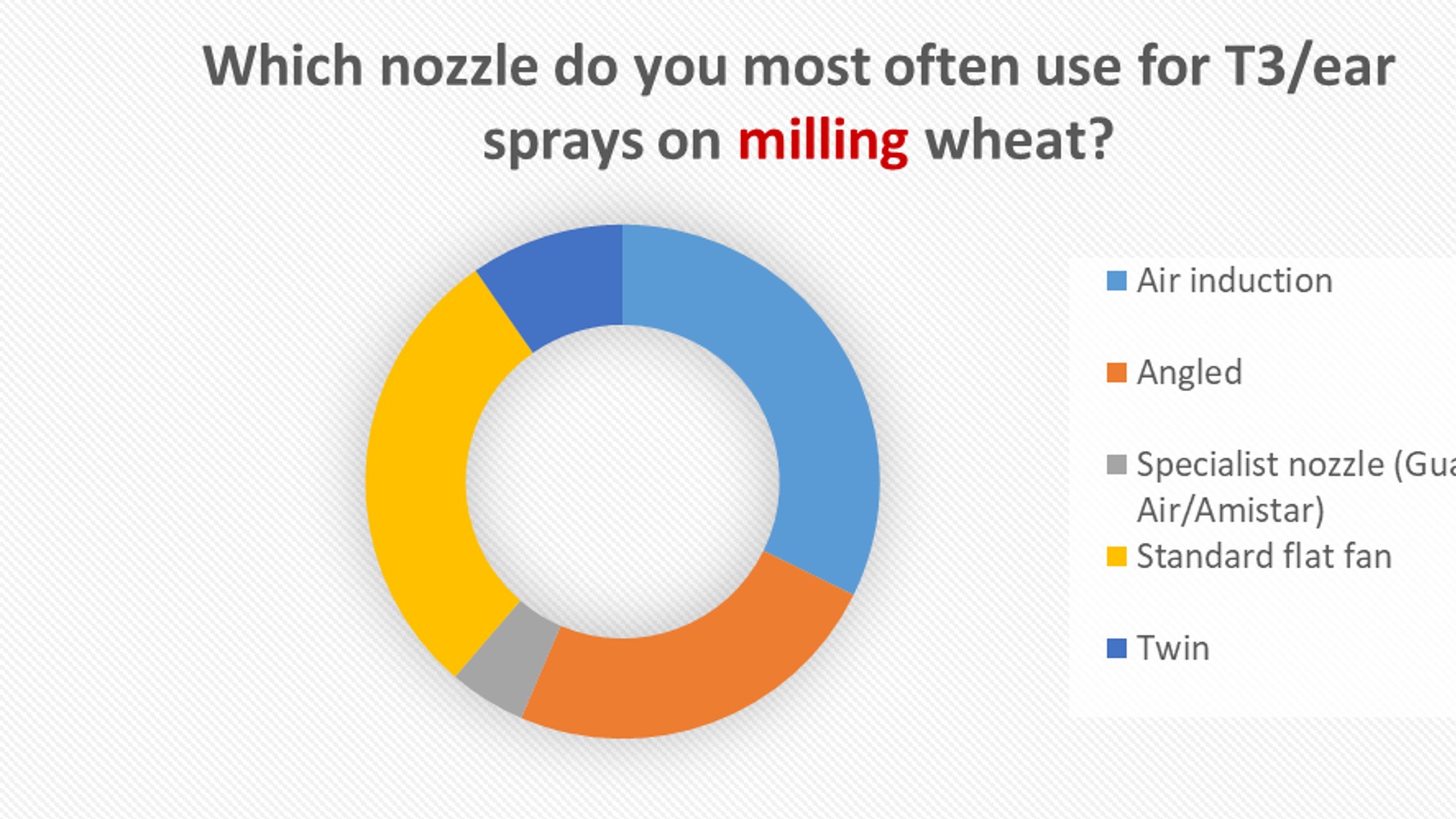

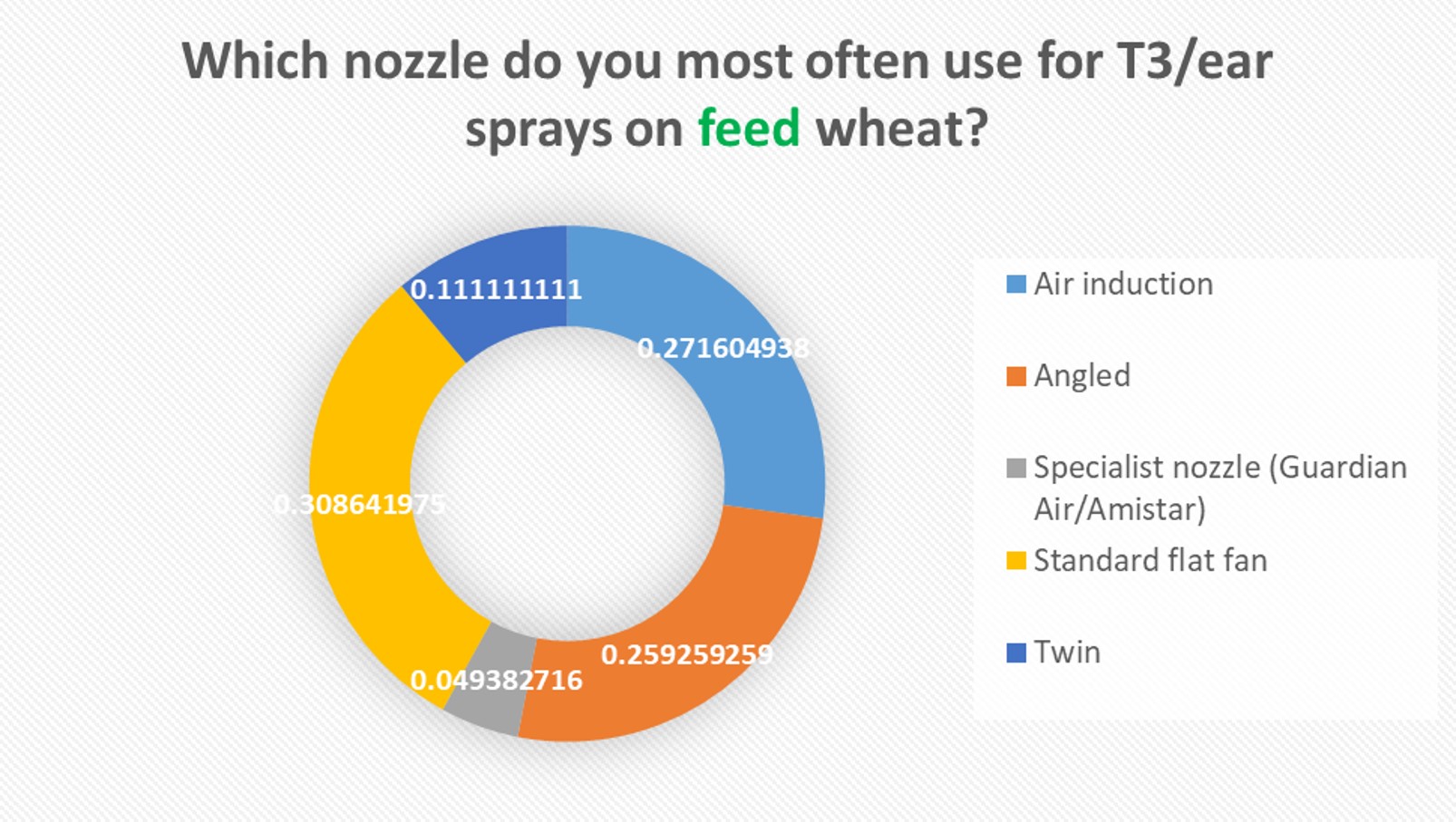

The survey showed growers made a range of nozzle choices, with an even distribution across air induction, angled and standard flat fan nozzle types. A small group of growers opting for twin or specialised nozzles, with little variation between the choices of milling and feed wheat growers.

Certainly nozzle type is important and work undertaken by Fera has shown that angled nozzles improve control, says Phil. They tested angled nozzles against vertical flat fans and saw a consistent improvement in fusarium control where angled nozzles were used with Proline, Folicur or Prosaro (prothioconazole+ tebuconazole). “For prothioconazole, Fusarium severity dropped to just 7%,” he notes.

Steve Gaiger of Collyer Farm Services in Hants has some sage advice, urging growers to think about what it is they’re trying to do with a T3 spray.

“The aim is to get full protection of the ear,” he says. “Achieving this is based on the quality of the spraying and spray deposition should override output of the sprayer.”

Collyers operate three self-propelled Bateman RB35 sprayers to service their own farm needs and a successful contracting business across the south east of England. Angled nozzles are now the norm for his ear sprays, says Steve.

He believes it’s common sense to attack vertical targets from sideways on. “Look down on the ear and it’s a small target, not dissimilar to a blackgrass stem. It’s also not a flat target, it has grains down the side. It stands to reason that spray angled to come in on the side axis will protect spikelets better,” he comments.

While he believes angled nozzles are best, a similar result can be achieved without them, he says. “For those with standard flat fan nozzles, it can be done by fitting different caps to give an angled spray. Another option is to alter the angle of air sleeves if fitted, or the boom tube itself. Whilst that won’t match the performance of an angled nozzle, it is better than applying a fungicide from above,” he suggests.

Steve is a big advocate of flat fan nozzles and considers them the gold standard in a number of alternative situations, but feels conditions need to be near to the optimum regardless of spray target. June is typically one of the drier months of the year, but the UK average is still ten days with rain so optimum conditions can be in short supply. For that reason, at T3 the Guardian Air or Defy 3D nozzle set at an angle is more the common choice for Steve.

“Both reduce drift and a tall crop does draws the spray in, but a low drift nozzle is the better option when conditions aren’t ideal or there’s a need to extend working time.”

Either way he prefers a fine pattern. “It’s about contact and penetration of the target and that’s best achieved with a finer spray pattern than with a coarse one. You’re looking to protect every spikelet and you won’t see fungicide systemic activity in the ear like you do a leaf,” he says, pointing out the importance of achieving good coverage.

He always sets nozzles in an alternating forward and rear-facing pattern. This ensures coverage of both sides of the ear and creates less turbulence, reducing drift. Nozzles are centred 50cm apart, at a boom height of 50cm above the crop.

Travel speed and boom height may not be considered vitally important with a big, ‘exposed’ target like the ear but Steve urges operators not to sacrifice control of the boom in order to cover more acres. He rarely travels above 12 km/h, even when using products at rates of 100 l/ha.

“Again, it’s all to do with accuracy over output. The faster you go, the greater the spray pressure needs to be. What you have to ask is whether the boom can handle it.”

Boom automation has taken much of the hard work out of setting up and stability, but he still feels traditional ideas have a place. “A 50cm tie strap attached to the boom is a simple guide to ensure the right boom height is maintained.”

He’s also reluctant to spray in the middle of the day. “As temperatures rise, evaporation increases which must have a bearing on spray deposition. Again, you risk compromising fusarium control if you spray in less than ideal conditions,” he concludes.

What is Fusarium ear blight?

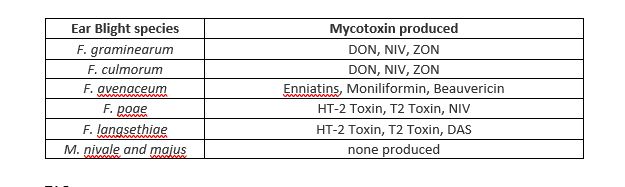

Fusarium ear blight is caused by a complex of seven different fungal species in the genus Fusarium, Giberella and Microdochium which vary in abundance and relative proportions from year to year. FEB is gradually increasing in incidence in UK and also occurs on barley, oats, rye and triticale.

FEB mycotoxin production

Recently the dominant species in the UK have been Fusarium culmorum, F. graminearum, F. poae and Microdochium nivale. Of these, F. culmorum and F. graminearum produce the toxins DON (deoxynivalenol) and ZON (zearalenone) in addition to reducing yield. There are strict European guidelines for levels of DON and ZON in grain.

Microdochium nivale occurs on infected debris and is also spread by infected seed, causing seedling blight and foot rot. It’s abundant but does not produce mycotoxins.

Both F. culmorum and F. graminearum can also infect the stem base, causing foot rot, which leads to early senescence and reduced yields. Both species release spores that spread to infect the ears at flowering. For F. culmorum, this is by rain-splashed asexually-produced spores called conidia, while for F. graminearum, wind dispersed sexually-produced spores (ascospores) act as inoculum. These are released from fruiting bodies at the stem base or infected crop debris from previous crops.

FEB disease symptoms appear as patches of early senescence and bleaching on the ears, with harvested grains appearing pale, shrivelled and often tinged with pink pigmentation.

Source: Croprotect