A focus on emissions and climate change won’t just help the planet, it could actually add to your productivity. CPM explores how fertiliser fares in the carbon calculations.

Achieving high yields should be seen as an environmental good, rather than indicative of environmental harm.

By Tom Allen-Stevens

Agriculture gets a bum rap when it comes to climate change and as far as crop production is concerned, fertiliser use is often singled out as the bad boy. But is the burden of responsibility being unfairly laden onto growers’ nitrogen practice?

For Anke Kwast, vice president of Yara’s climate-neutral roadmap, it goes far wider than the farm. “Fighting climate change is crucial for all of us. We’re seeing increasingly extreme weather conditions, and there are many steps we must take to combat this. But one important step we must all make as consumers is a positive commitment towards Net Zero, as this will be a strong drive for transformation,” she says.

“For Yara climate change is a real concern. We have an aim to be climate neutral by 2050 in our own production and we also actively contribute towards the transformation of the whole food chain towards climate neutrality.”

Agriculture accounts for around a quarter of greenhouse gas emissions (GHG) of which crop production makes up another quarter. “From the food chain perspective, about a quarter of the GHG emissions of bread comes from farming, for example, of which 30-40% are emitted from the soil and around 25-30% are related to the production of fertiliser. So both emissions from the soil and fertiliser must be addressed to decarbonise the food chain,” notes Anke.

But the size of that slice depends on where your fertiliser comes from. Yara, along with other European fertiliser manufacturers, has already introduced abatement technology that has reduced the nitrous oxide (N₂O) emissions associated with its manufacture by more than 90%. These emissions are around 300 times more impactful than carbon dioxide (CO₂), Anke points out. “That means that fertiliser from Europe has around half the carbon footprint as fertiliser from other origins.”

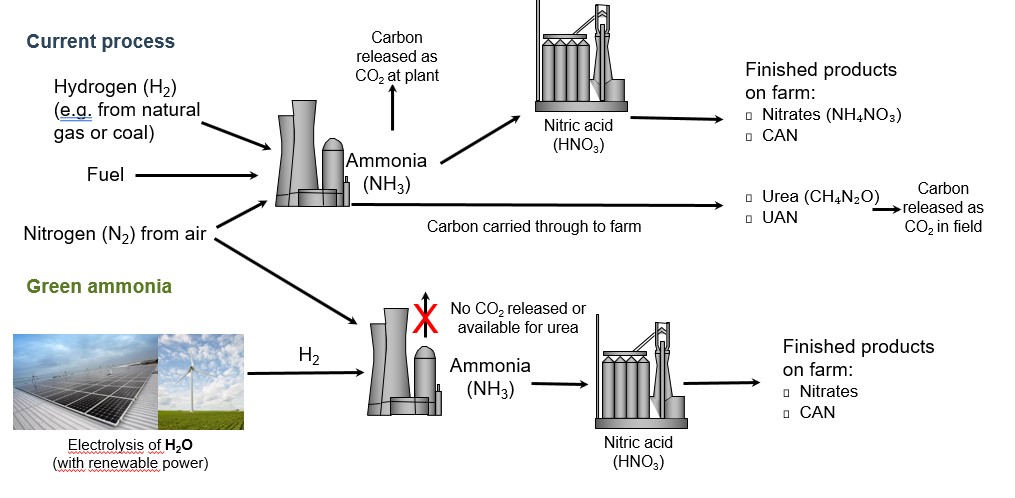

The next step for Yara is a green ammonia programme that uses renewable energy technologies to produce hydrogen by electrolysis from water, capture nitrogen from the air and combine these to form ammonia. It’s a new take on the Haber Bosch process used for over a century and currently fuelled by natural gas, or in some countries coal, which is responsible for releasing vast quantities of CO₂. The green ammonia process uses spare electricity from wind farms and is totally carbon-free.

The next step for Yara is a green ammonia programme that uses renewable energy technologies to produce hydrogen by electrolysis from water, capture nitrogen from the air and combine these to form ammonia. It’s a new take on the Haber Bosch process used for over a century and currently fuelled by natural gas, or in some countries coal, which is responsible for releasing vast quantities of CO₂. The green ammonia process uses spare electricity from wind farms and is totally carbon-free.

Another important route to reduce GHG emissions, and one with a clear financial benefit on farm, is to improve nitrogen use efficiency (NUE), continues Anke. “Using precision application techniques, the NUE can be increased from around 60% current average in Europe to 80% – this has been demonstrated in trials.”

In the UK, many such trials have been carried out by ADAS, and in more recent years ADAS has amassed datasets on the yields and inputs of growers in the Yield Enhancement Network (YEN). With funding from The Morley Agricultural Foundation, researchers have explored the evidence and assumptions with respect to GHG and found all is not as it seems.

“Most people, even farmers, believe that high crop yields need lots of fertiliser and other inputs which worsen the environmental impacts of farming,” says Dr Daniel Kindred, head of Agronomics at ADAS. “Our analysis shows that achieving high yields should be seen as an environmental good, rather than indicative of environmental harm.”

The reason for this, Daniel explains, is that agriculture is the only industry that removes CO₂ from the atmosphere, through photosynthesis, to produce energy rich products.

“A typical crop growing say 10t/ha grain produces 18t/ha of biomass above ground and an estimated 1.8t/ha in roots below ground. That means a typical grain crop fixes around 34t CO₂/ha. However, this carbon is released back into the atmosphere when the grain is consumed and when its residues decompose in the soil. Unless some of this carbon is retained, for example within stable soil organic matter (SOM), there’s no net reduction of atmospheric CO₂. So carbon fixation by crops is not normally considered in GHG calculations.”

But it’s not the carbon release from the soil that’s the concern. Far more damaging are the N₂O emissions related to manures, fertilisers, crop residues and composts applied to the soil. “Emissions of N₂O typically account for less than 5kg N/ha, so are unimportant agronomically. But their global-warming potential is huge – typically 0.6-1.5t CO₂e/ha (t of CO₂ equivalence) for grain crops.”

Another source to consider are the emissions associated with manufacture of fertilisers, and again N₂O has been the culprit. “There’s good news here – the fertiliser industry in the UK and Europe has invested very heavily over the past 10 years in technologies to abate these N₂O emissions. Many fertiliser manufacturers can now provide accredited GHG intensities for their products. Purchase wisely and the associated GHG are around 0.7t CO₂e/ha but this can be much higher.”

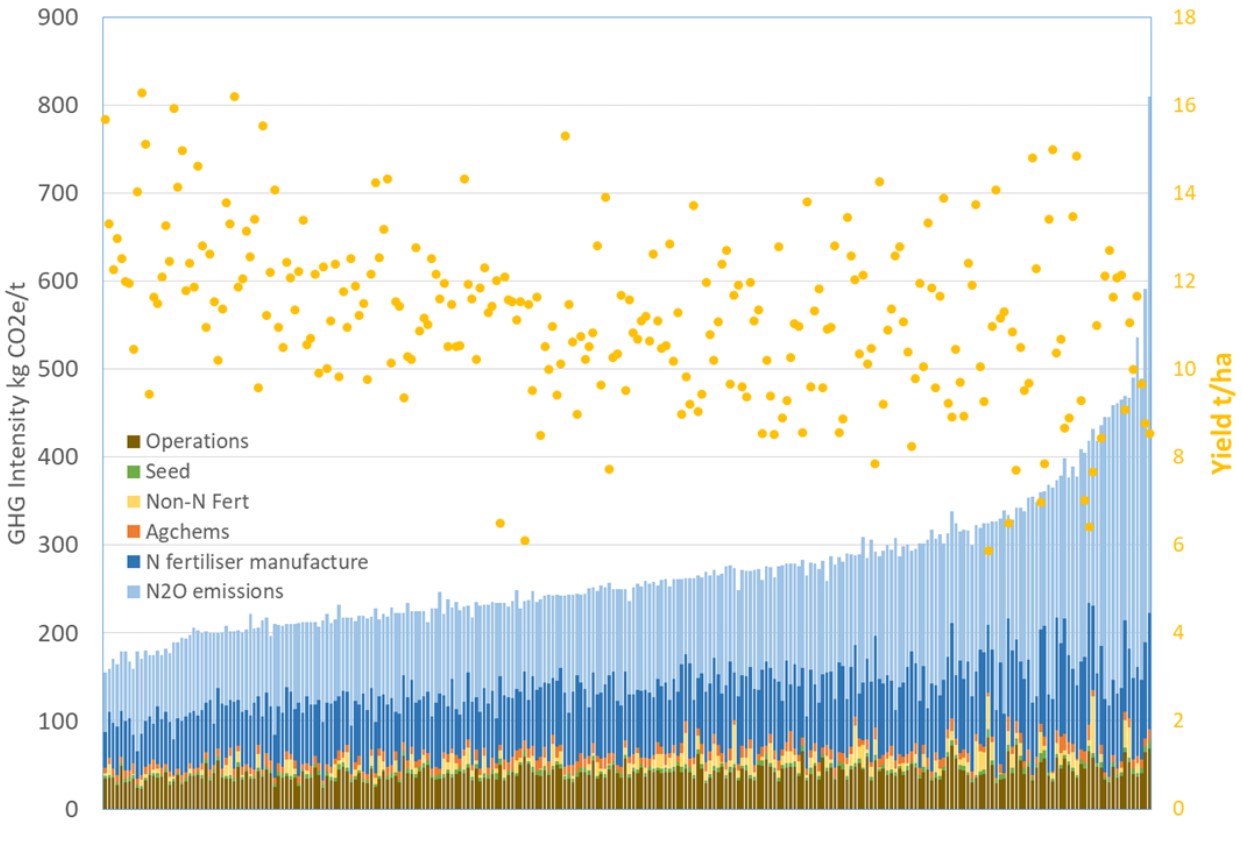

While the total emissions from a typical cereal crop are around 3t CO₂e/ha, what matters is the GHG intensity per t of grain, Daniel argues, and this was calculated for the YEN dataset where sufficient information on inputs was available.

“This clearly shows the dominance of N fertiliser and N₂O emissions on the carbon intensity of cereal grains – together these account for more than 70% of the total. It can also be seen that the lowest GHG intensities per t are often achieved where the yields are high, and vice versa. However, the biggest drivers of variation in GHG intensities are the emissions from N fertiliser use and associated N₂O emissions.”

N₂O emissions from the soil result from the nitrification of ammonium to nitrate and, in anaerobic conditions, from denitrification of nitrate to ammonium, he explains. From a GHG calculation perspective, for any N you add to the soil, a standard 1% is assumed to be emitted as N₂O, as defined by IPCC.

This was explored in the cross-industry MINNO project that ADAS led from 2009 to 2015. What researchers found was that typical emissions from fertiliser applications in the drier arable regions of the UK were substantially less than the 1% standard, but higher from wetter soils. This means that applying 200kgN/ha in dry regions with 600mm annual rainfall gives N₂O emissions of 0.66t CO₂e/ha, while the same application in a wetter region with 1200mm rainfall would give emissions of 1.7t CO₂e/ha.

So how should N rates be adjusted to optimise crop GHG intensities? “Previous work has shown that the minimum GHG intensity is achieved at only 30kgN/ha, while the economic optimum for yield is around 200kgN/ha,” notes Daniel.

“However, this calculation ignores the consideration that any grain not produced here due to lower yields will likely have to be produced by increased production somewhere else. That increases pressure for land use change and the consequent huge carbon losses from vegetation and soil that result from the conversion of natural grassland or forest to crop land.”

Factoring in this indirect land use change (ILUC), shows there’s little difference in overall emissions between N rates of 100 and 200kgN/ha.

The net effect of ILUC is significant, he says – every 1t less wheat grain produced in the UK can result in an emissions burden of 1.8t CO₂e elsewhere in the world where land is converted to meet the shortfall.

Estimated GHG intensities for YEN cereal crops. Source: ADAS YEN, 2013-2019; constituent parts of GHG shown in columns and on left axis, yields achieved are yellow dots on right axis.

“This also suggests there’s a large under-recognised benefit from enhancing yields. Many farms in the YEN consistently achieve yields higher than 12t/ha, where national average yields are 8t/ha. It could be argued that these farms are contributing 7t CO₂e/ha simply through reducing ILUC.”

Keen to take this research forward, ADAS has recently launched YEN-Zero, highlights crop research consultant Dr Christina Baxter. “The plan is to bring together a community of interested farmers, advisors, industry, researchers and policy makers. We want to develop shared understanding, to share ideas and data, to enable comparisons and benchmarking, and to derive insights. These will form hypotheses that can be tested on-farm that can help us achieve Net Zero crop production.”

The aim is for more clarity and transparency behind what she calls “the black box” of how emissions are currently calculated. “By breaking it down and simplifying it, we can work with growers towards strategies that can mitigate emissions.”

As well as maximising the use of the land, ensuring it’s yielding its best potential, applying appropriate rates of fertiliser to meet crop demand is key, she says, and growers should aim to apply rates that differ no more than 50kgN/ha from the optimum to avoid waste.

“Compaction will affect the efficiency of crop nutrient uptake as well as creating anaerobic conditions which exacerbate N₂O emissions,” she notes.

“Most of all, our work with YEN has shown it’s the ‘Farm Factor’, the attention to detail in management of the crop and soil that pays, not the amount spent on inputs. That tends to deliver higher yields which will have a lower GHG intensity per tonne of grain,” Christina concludes.

Greater precision on farm aids efficiency and reduces emissions

Fertiliser can present a conundrum for farmers, notes Natalie Wood, Yara arable agronomist for UK and Ireland. “Nitrogen fertiliser plays a key role in enhancing food production to feed a growing global population. But overuse leads to soil, air and water pollution, not to mention leaving a dent in your bank balance. There’s a balance to be struck. The key to greater efficiency is precision agronomy.”

There are simple things growers can do, she explains:

Know your soil

Taking regular soil analysis over the years helps to build up a picture of your land and how fertile it is. This will allow you to be more accurate with your choice of fertiliser, applying only those nutrients that your soil is deficient in and your crop needs.

Focus on the growing crop

In spring, leaf analysis comes into play, detailing exactly what developing deficiencies crops have, so you can act quickly to avoid issues that will affect yield. Using tools such as Yara’s N-Tester BT, that measures leaf nitrogen in a growing crop, gives an accurate field-specific nitrogen requirement, reducing wastage.

Increase nitrogen use efficiency

Natalie believes there are three elements here that make a difference:

- Choose the right fertiliser – A compound rather than a blend ensures an even application of all nutrients.

- Vary the application – Field nitrogen requirements are never constant, yet often the application of nitrogen fertiliser is. Tools such as Yara’s N-Sensor and Atfarm software can be used to make variable nitrogen application that meet crop requirements, rather than wasteful blanket applications.

- Spread at the right time – different types of fertiliser release their nitrogen in the plant-available nitrate form at different rates. A good understanding of the differences ensure you get the timing of nitrogen availability right.

Grow the future

Climate change, societal demands, changing consumer trends and not least the weather – one thing that’s certain about farming is that it’s anything but predictable. So the best farms must be efficient enough to grow crops both sustainably and profitably now and in the future.

Few aspects of crop production are more critical in this than a plant’s nutrition, which is why CPM has teamed up with Yara. This series of articles looks at some of the innovations coming into this area and the practical steps needed to ensure your farming system is set to grow the future.

With decades of evidence-based knowledge, Yara continues to be at the forefront of crop macro and micronutrient advice. Investment in technology has resulted in world-leading products that support in-field decision-making and precision nitrogen application.