Keep the boom low, travel slow and apply pre-em herbicides with plenty of water, say Syngenta’s spray-application team. CPM catches up with research that shows the incredible difference it makes on blackgrass.

By Tom Allen-Stevens

Growers could be losing up to 80% efficacy of their pre-emergence blackgrass herbicides purely because they’ve been applied incorrectly.

Research carried out by Syngenta’s spray application team has found there are three key areas where herbicides are losing efficacy as a result of poor application practice:

- Forward speed – ideally this should be 6km/h

- Boom height – this should be 50cm

- Water volume – the best results are at 200 l/ha.

The team have also assessed 90% drift-reduction nozzles and strongly advise spray operators switch over to these when conditions are less than ideal.

Full details of the research and application advice, including bite-size videos are available on the Syngenta website.

James Thomas is hosting a webinar through Facebook to offer more advice and answer specific queries.

Application specialist James Thomas is also hosting a webinar through Facebook at 8:00am on Weds 6 Sept to offer more advice and answer specific queries on pre-em application efficacy.

“For many growers now, the pre-em spray is the single bite of the cherry you have to get blackgrass under control using herbicides,” he notes.

“You can easily spend in excess of £100/ha. It doesn’t cost any more to ensure a good result, but our trials have shown the difference where a pre-em has been poorly applied is incredible.”

Boom sway

The aim is an even coverage across the soil surface. Boom sway and yaw and spray drift can often have a more marked effect on efficacy of pre-ems than other applications, says James.

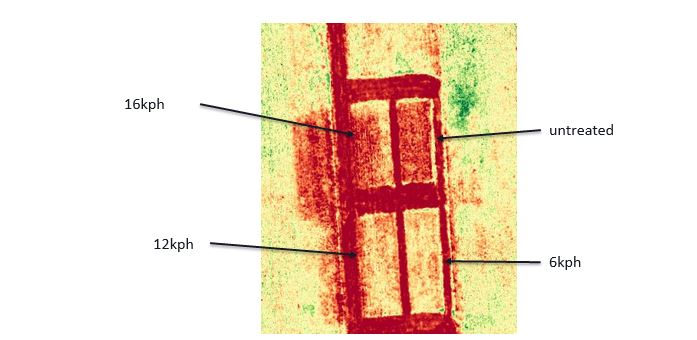

“On the continent, many operators travel at just 6km/h to ensure good coverage, yet in the UK the typical forward speed is 12-16km/h. Our trials show a reduction in efficacy of up to 40% from forward speed alone.”

This drone scan pic, which shows up blackgrass in the trials plots in red, shows the difference forward speed makes.

Keeping booms at the recommended 50cm height above the soil can be hard, he accepts, especially when the slightest bump at speed can cause damage, but independent research has shown raising this to 1m increases drift by ten times.

“Our trials show this also reduces blackgrass control by 17%,” he adds.

While 100 l/ha is the standard water volume used for many applications, this should be raised to 200 l/ha with pre-ems. “Our trials show a reduction in efficacy of 40% if you halve water volume to 100 l/ha.”

Drift-reduction nozzles

He also strongly recommends spray operators make good use of 90% drift-reduction nozzles. “In ideal conditions, the 3D nozzle is unchallenged as by far the best choice,” notes James.

Using drift-reduction nozzles when conditions are less than ideal is good practice and there’s no drop in efficacy.

“But in many parts of Europe, regulation enforces the use of drift-reduction nozzles. That’s not currently the case in the UK, but it is good practice, especially for applications made when conditions are less than ideal.

“Our trials have shown no drop in efficacy through using these nozzles, and it helps compliance with very complex buffer-zone regulations, as well as demonstrating good practice, which will help preserve the chemistry we have available.”

Full details on James’ three favoured drift-reduction nozzles can also be found on the Syngenta Pre-em Application web page.